Home » The 7 Pillars of The Custom Packaging Unboxing Experience

The 7 Pillars of The Custom Packaging Unboxing Experience

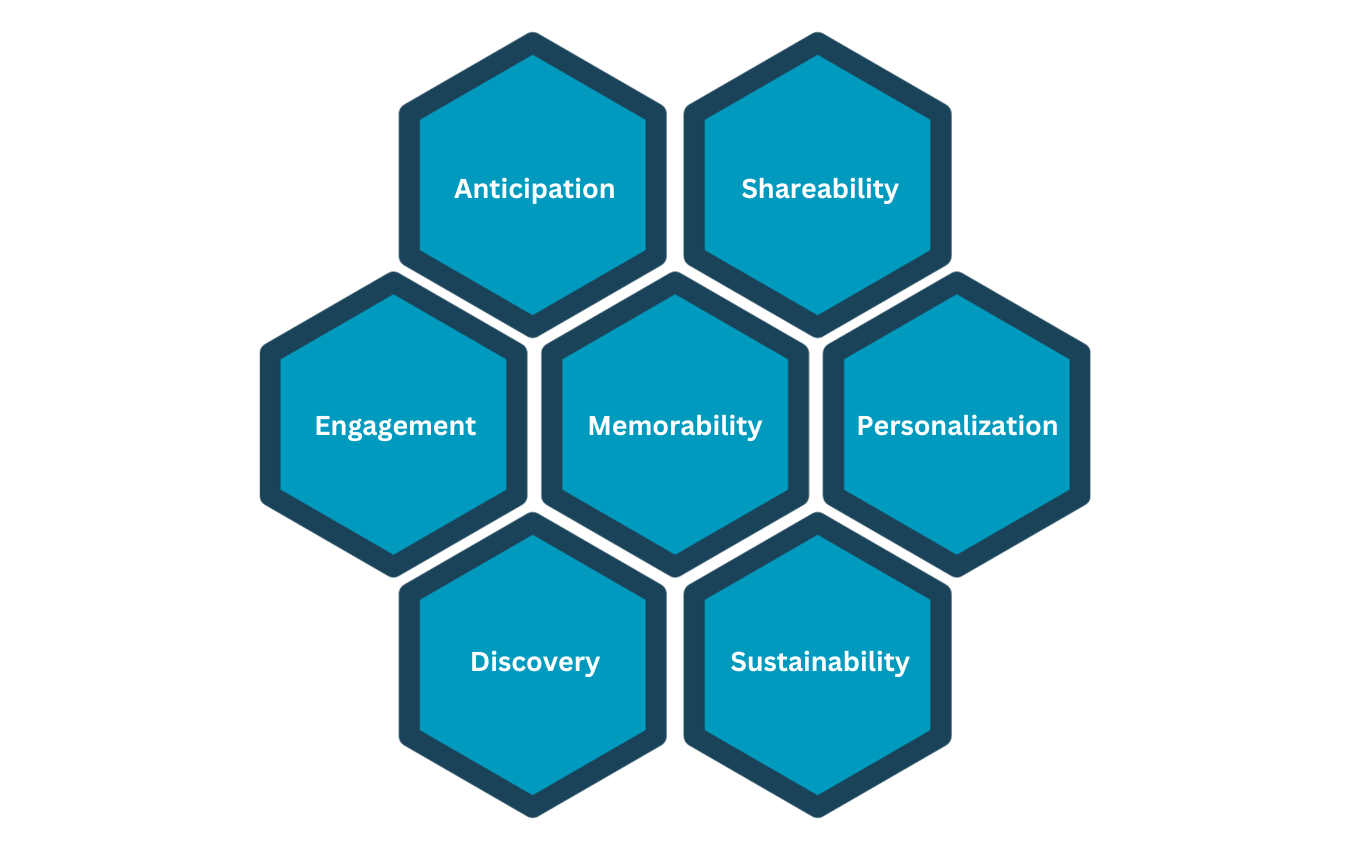

In today’s competitive marketplace, it’s not enough for a product to be high-quality; it must also provide an exceptional experience from the moment it arrives at the customer’s doorstep. Much like the principles of User Experience (UX) design, creating an engaging and memorable unboxing experience is crucial. We’ve adapted Peter Morville’s UX Honeycomb to create a Custom Packaging Honeycomb, which comprises seven essential factors for designing the perfect unboxing experience.

Anticipation: Building Excitement

Before the box is even opened, the unboxing experience should begin by generating anticipation. Consider the use of eye-catching visuals on the packaging, teasing what’s inside, and creating a sense of excitement.

Think about Apple’s iconic product packaging; it teases the product within, leaving customers eager to explore further.

Engagement: Holding Attention

A great unboxing experience should be engaging, holding the customer’s attention throughout. Use creative design, storytelling, or interactive elements within the packaging to keep customers captivated.

Brands like Glossier use colorful packaging and personalized notes to maintain engagement, making customers feel special.

Discovery: Easy Exploration

Customers should easily discover and explore the different layers, compartments, or elements of your packaging. Hidden surprises or information should be intuitively found, adding an element of delight.

Memorability: Leave a Lasting Impression

A memorable unboxing experience stays with customers long after they’ve opened the box. Aim to create an experience that’s shareable and worth remembering, fostering brand loyalty.

Luxury brands like Tiffany & Co. have mastered the art of creating memorable unboxing experiences, from the signature blue box to the white satin ribbon.

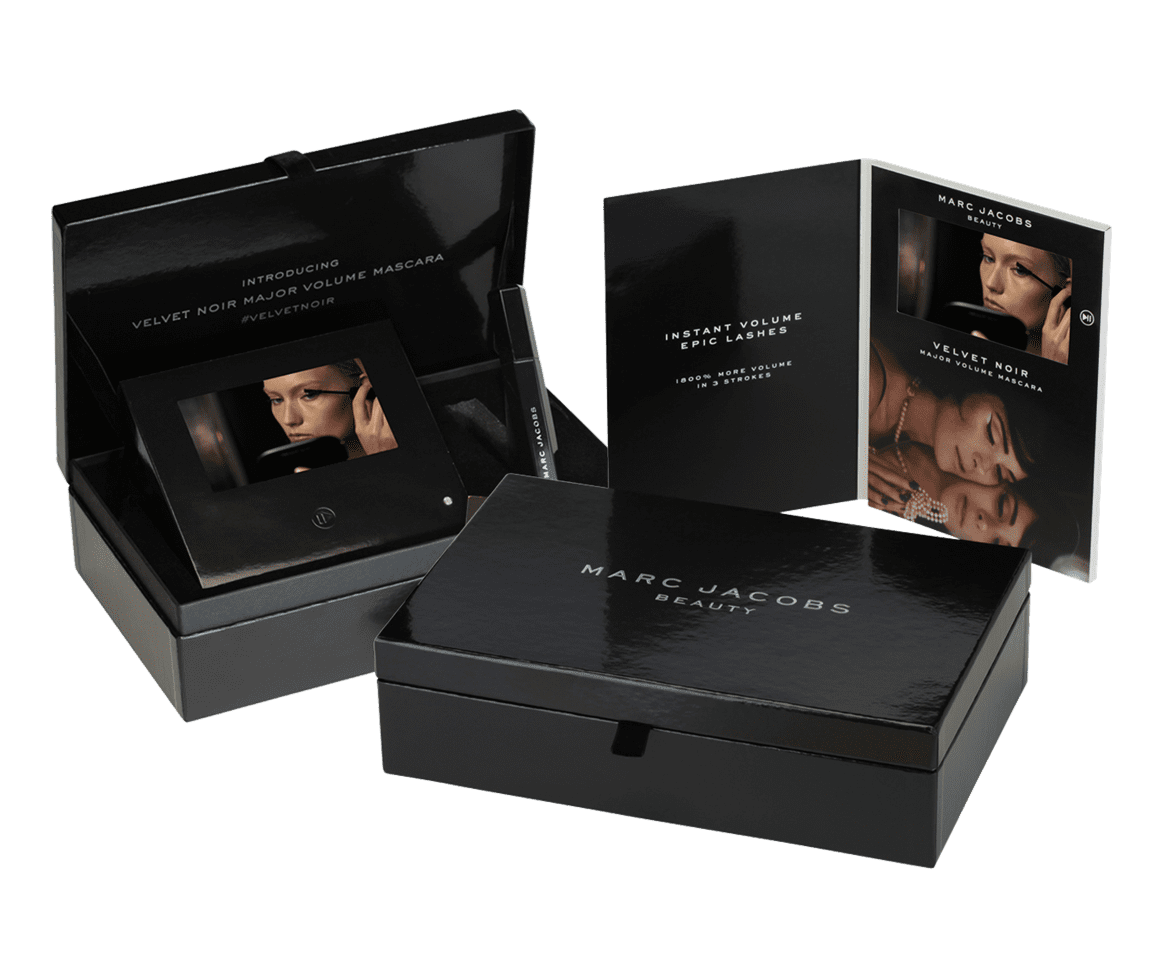

Shareability: Encourage Social Sharing

Leverage the power of social media by designing an unboxing experience that’s shareable. Encourage customers to snap pictures or record videos of their unboxing moments, spreading brand awareness.

Beauty companies like Sephora design packaging that customers love to share on Instagram, expanding their reach organically.

Personalization: Tailor to the Individual

Whenever possible, personalize the unboxing experience for each customer. This could include handwritten notes, customized packaging, or product recommendations based on their preferences.

Sustainability: Mindful of the Environment

In an era of growing environmental awareness, sustainable packaging practices are essential. Use eco-friendly materials and provide clear instructions on how to recycle or reuse the packaging.

Brands like Patagonia are known for their commitment to sustainability, extending it to their packaging materials.

Conclusion

The Custom Packaging Honeycomb provides a framework for creating unboxing experiences that delight customers and strengthen brand loyalty. By incorporating these seven factors – anticipation, engagement, discovery, memorability, shareability, personalization, and sustainability – brands can ensure that the unboxing experience is as exceptional as the product itself. As the e-commerce landscape continues to evolve, remember that the unboxing experience can be a powerful tool for setting your brand apart and leaving a lasting impression on customers.

If you are interested in custom packaging, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Home » The 7 Pillars of The Custom Packaging Unboxing Experience

Storage solutions are essential for any business who wants to organize their space efficiently. One of the most effective and economical options are corrugated bin

Lithography in packaging is a process used to print high-quality graphics and text on various substrates, such as plastics and paper. This technique is used

Launching a product in a retail chain or club store is a significant milestone for any brand. However, this process can come with challenges, particularly