Sustainable Packaging

Explore our sustainable packaging products, including corrugated boxes, folding cartons, pouches, and stock packaging options. We offer eco-friendly materials and a variety of print and ink choices to fit your packaging needs. Choose from solutions designed to support sustainability and meet your business requirements.

Sustainable packaging refers to the use of materials and design methods that minimize environmental impact. This can include using recyclable or biodegradable materials, reducing excess packaging, and opting for renewable resources like paper, kraft, or corrugated materials. The goal is to reduce waste, conserve energy, and lessen the overall carbon footprint of packaging.

By choosing sustainable packaging, businesses help limit the negative effects of packaging waste on the environment. These products are often recyclable, compostable, or reusable, making them a more eco-friendly option. Sustainable packaging balances the need for protection and branding with the responsibility to preserve resources for future generations.

Our sustainable packaging products include custom corrugated boxes, folding cartons, pouches, and a variety of stock options. Each product is designed with eco-friendly materials to help reduce environmental impact while meeting your packaging needs.

Corrugated Boxes

- Regular slotted Container (RSC)

- Half Slotted Container (HSC)

- Full Overlap (FOL)

- Roll End Tuck Top (RETT/Mailer)

- Additional Box Styles

- Corrugated Inserts

Folding Cartons

- Straight Tuck End (STE)

- Reverse Tuck End (RTE)

- Full Seal

- Auto Bottom

- Chipboard Inserts

Pouches

- Stand Up

- Lay Flat

- Gusseted

- Retort

- Block Bottom

- Sachets

- Additional Pouch Styles

Stock Packaging Products

- Corrugated Packaging

- Shipping Boxes

- Chipboard Packaging

- Edge Protectors

- Mailers (Kraft)

- Kraft Tape

- Kraft Paper

At Brown Packaging, we prioritize eco-friendly packaging solutions that help reduce environmental impact. Our commitment to green packaging ensures that we provide sustainable materials, allowing you to make responsible choices for your business and the planet.

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

We provide packaging solutions designed to help reduce your carbon footprint through eco-friendly production, efficient shipping, and sustainable materials. From pallet optimization to energy-efficient manufacturing, our approach ensures that your packaging minimizes environmental impact at every stage.

Our custom structural design services allow us to minimize material use without compromising protection. By optimizing the design for strength and efficiency, we help you reduce excess packaging and the environmental costs associated with waste. Smarter packaging design means a lower carbon footprint overall.

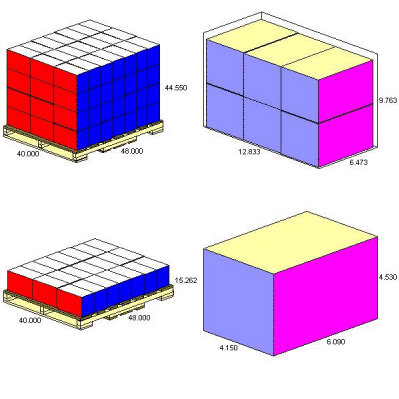

With CAPE software, we optimize pallet configurations to maximize space and load efficiency. This results in fewer trips and lower fuel usage during transportation, reducing your carbon footprint. By making the most of every pallet, we help you achieve more eco-friendly logistics.

We offer digital samples, eliminating the need for multiple physical prototypes, which reduces waste and energy use in production. By creating virtual models, we help you save resources while speeding up the design process. This eco-friendly approach helps minimize the carbon footprint of packaging development.

We focus on eco-friendly production processes that minimize waste and reduce energy consumption. By using sustainable materials and optimizing manufacturing efficiency, we help lower the carbon footprint of your packaging. This commitment to sustainable production ensures a smaller environmental impact from the start.

Our lightweight and efficient packaging solutions help reduce transportation emissions by maximizing space and minimizing weight. By designing packaging that is easy to transport, we help your business cut down on fuel consumption and overall shipping costs, contributing to a reduced carbon footprint.

We design packaging with durability and reusability in mind, extending the useful life of each product. By creating packaging that can be used multiple times before disposal or recycling, we help reduce waste and conserve resources, contributing to a smaller environmental footprint.

We prioritize sourcing materials from local suppliers to reduce transportation distances and emissions. By keeping production and distribution close to home, we help cut down on the environmental impact associated with long-distance shipping. Local sourcing ensures a more sustainable and efficient supply chain.

We offer packaging made from eco-friendly, recyclable, and biodegradable materials that reduce reliance on virgin resources. By using sustainable materials, we help decrease the carbon emissions associated with material extraction and production. This ensures that your packaging has a smaller environmental impact from the very start.

Interested In Sustainable Packaging Solutions?

Discover the latest insights on sustainable packaging by exploring our blog, where we share tips and innovations to help businesses reduce their environmental impact. Stay informed about eco-friendly packaging solutions and learn how your company can make a difference through sustainability.

In the ongoing battle against environmental degradation, California has emerged as a leader in the fight to reduce single-use plastics. With a series of comprehensive laws and regulations, the Golden State has taken bold steps to curb the use of these harmful materials. Bans on single-use plastic bags, straws, and expanded polystyrene (Styrofoam) food containers are just a few examples of California’s commitment to a greener future. In this blog, we’ll explore these regulations and their significant implications for packaging choices, particularly within the food and beverage industry. California’s Stringent Regulations on Single-Use Plastics California’s proactive stance on reducing single-use plastics has resulted in several impactful regulations: Ban on Single-Use Plastic Bags: In 2014, California became the first state in the U.S. to ban single-use plastic bags at most retail stores. This groundbreaking law aimed to reduce plastic pollution, encourage reusable bag usage, and promote sustainability. Straws on Request: Under the “Straws on Request” law that took effect in 2019, restaurants in California can only provide plastic straws upon customer request. This measure significantly reduces the distribution of single-use plastic straws, minimizing plastic waste. Ban on Expanded Polystyrene (Styrofoam) Food Containers: California implemented a ban on expanded polystyrene (EPS) foam food containers in 2020. The use of EPS for takeout containers, cups, and plates is now prohibited due to its environmental impact and persistence in the environment. The California Circular Economy and Plastic Pollution Reduction Act: Enacted in 2020, this law sets ambitious targets for reducing plastic waste and increasing recycling rates in California. It encourages manufacturers to use more recycled materials in their products and promotes a circular economy for plastics. Implications for Packaging Choices in the Food and Beverage Industry California’s stringent regulations on single-use plastics have far-reaching implications for businesses, particularly those in the food and beverage industry: Adoption of Sustainable Alternatives: With bans on EPS foam containers, businesses must seek sustainable alternatives for packaging. This shift has led to the adoption of compostable or recyclable materials, such as paper-based packaging, reusable containers, and innovative eco-friendly materials. Emphasis on Reusability: The ban on single-use plastic bags and straws has placed a renewed emphasis on reusable packaging options. Restaurants and food establishments are increasingly offering reusable containers and encouraging customers to bring their own bags and containers. Focus on Eco-Friendly Packaging Designs: As businesses seek to comply with California’s regulations, they are investing in packaging designs that are both functional and environmentally responsible. This includes using materials that are easily recyclable or compostable and reducing excessive packaging. Consumer Awareness and Preference: California consumers are becoming more aware of environmental issues, leading to a preference for businesses that embrace sustainable packaging practices. Packaging choices that align with these preferences can be a competitive advantage. If you are interested in packaging solutions in California, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

When it comes to packaging and transporting bicycles, one type of corrugated box stands out as the ideal choice: Full-Overlap (FOL) Corrugated Boxes. These specially designed boxes offer superior protection and structural integrity, ensuring that your valuable bikes reach their destination in perfect condition. In this detailed blog, we’ll explore why Full-Overlap Corrugated Boxes are the right choice for bikes, discussing their unique features, benefits, and why they outshine other packaging options. Understanding Full-Overlap Corrugated Boxes Full-Overlap Corrugated Boxes are a type of corrugated packaging specifically engineered for robustness and durability. They are characterized by their design, which involves flaps that fully overlap when the box is closed. This design provides exceptional strength and protection, making them ideal for safeguarding items like bicycles during transit. Why Full-Overlap Corrugated Boxes Are Ideal for Bikes Superior Protection: FOL Boxes provide a high level of protection due to their sturdy construction. They effectively shield bikes from impacts, vibrations, and external forces during shipping. Structural Integrity: The overlapping flaps of these boxes enhance their structural integrity, preventing crushing or deformation, which is crucial when shipping bicycles. Customizable Sizing: FOL Corrugated Boxes are available in various sizes, ensuring a snug fit for different bicycle types and sizes. Custom sizing minimizes excess space, reducing the risk of damage due to movement during transit. Shock Absorption: These boxes are designed to absorb shocks and vibrations, preventing potential damage to delicate bicycle components like gears, brakes, and frames. Secure Closure: Full-Overlap Corrugated Boxes typically feature secure closures, such as adhesive tape or strapping, ensuring that the box remains closed throughout the shipping process. Cost-Efficient: Despite their advanced protection capabilities, Full-Overlap Corrugated Boxes are cost-effective, providing a balance between safeguarding your bikes and managing shipping expenses. Eco-Friendly Options: Many Full-Overlap Corrugated Boxes are made from recyclable materials, aligning with eco-conscious packaging practices. Branding Opportunities: These boxes can be customized with your brand logo and information, enhancing your company’s visibility and professionalism. Other Considerations for Bike Packaging While FOL Corrugated Boxes are the ideal choice for bike packaging, it’s essential to consider a few additional factors: Padding and Cushioning: Use appropriate cushioning materials, such as foam and corrugated inserts or bubble wrap, to further protect delicate bike components. Customization: Consider customizing the interior of the box to accommodate specific bike models or accessories securely. Labeling and Documentation: Clearly label the boxes with shipping information and handling instructions. Include relevant documentation, such as assembly instructions or warranty information, if applicable. Shipping Method: Choose a reliable shipping method and carrier to ensure that your bikes are handled with care during transit.Top of Form If you are interested in bike packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated ESD Design Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Bike Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

In the ever-evolving world of packaging, finding the perfect combination of features that ensures both security and ease of use can be a challenging endeavor. Roll end tuck top (RETT) boxes have long been recognized for their durability and versatility, and when you introduce the dynamic duo of dust flaps and cherry locks, you take your packaging game to the next level. In this blog, we will delve into the intricacies of these two features and explore how their synergy enhances the functionality and appeal of RETT boxes. Understanding Dust Flaps Dust flaps are extensions from the top of the box that fold down when closed. Their primary function is to protect the contents from dust, dirt, and contaminants. However, when paired with cherry locks, they bring an additional layer of security and sophistication to the packaging: Security: Dust flaps provide an extra barrier against tampering and unauthorized access, ensuring the contents remain intact and untouched. Presentation: When opened, dust flaps add to the overall presentation, creating a polished and professional unboxing experience that can be especially beneficial for premium or luxury products. Understanding Cherry Locks Cherry locks, on the other hand, are locking mechanisms that securely close the top flaps of boxes without the need for additional adhesives or tape. Their unique design features include: Reusability: Unlike traditional adhesive closures, cherry locks are reusable, making them both cost-effective and eco-friendly. Easy Access: Cherry locks are user-friendly, allowing for quick and effortless opening, which is essential for products that need frequent access. The Perfect Pairing: Dust Flaps and Cherry Locks in RETT Boxes When dust flaps and cherry locks come together in RETT boxes, they create a packaging solution that excels in both form and function: Enhanced Security: Dust flaps provide an additional layer of protection against external contaminants and tampering, while cherry locks ensure a secure closure that keeps the contents safe. Presentation Excellence: The combination of dust flaps and cherry locks enhances the unboxing experience, leaving a lasting impression on customers and making it ideal for products that demand a touch of sophistication. User-Friendly Design: Cherry locks make it easy for customers to access the contents repeatedly without compromising the box’s integrity, making them an excellent choice for subscription boxes and retail products. Customization Opportunities: Dust flaps and cherry locks offer ample space for branding elements, product information, or decorative designs, allowing you to reinforce brand identity and connect with your customers. Applications of Dust Flaps and Cherry Locks in RETT Boxes These features find applications across various industries: Retail: In retail packaging, the combination of dust flaps and cherry locks offers secure, easy-to-access solutions for items like cosmetics, electronics, and clothing. E-commerce: For e-commerce businesses, this pairing enhances security during shipping while providing a memorable unboxing experience for customers. Subscription Boxes: Subscription box services benefit from dust flaps and cherry locks as they offer security, easy access, and a branded presentation. Luxury and Premium Products: High-end products often require packaging that exudes sophistication, making dust flaps and cherry locks an ideal choice. Conclusion Dust flaps and cherry locks are a powerful combination that elevates the functionality and appeal of RETT boxes. Understanding their features, benefits, and applications can help businesses make informed choices when selecting packaging solutions. Whether you prioritize security, presentation, or ease of access, the integration of dust flaps and cherry locks into your RETT boxes can enhance your packaging strategy, ensuring that your products are not only well-protected but also delivered in style. If you are interested in roll end tuck top boxes with dust flaps and cherry locks, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Roll End Tuck Top (RETT) Facebook Twitter LinkedIn Pinterest Relevant Posts