Sustainable Packaging

Explore our sustainable packaging products, including corrugated boxes, folding cartons, pouches, and stock packaging options. We offer eco-friendly materials and a variety of print and ink choices to fit your packaging needs. Choose from solutions designed to support sustainability and meet your business requirements.

Sustainable packaging refers to the use of materials and design methods that minimize environmental impact. This can include using recyclable or biodegradable materials, reducing excess packaging, and opting for renewable resources like paper, kraft, or corrugated materials. The goal is to reduce waste, conserve energy, and lessen the overall carbon footprint of packaging.

By choosing sustainable packaging, businesses help limit the negative effects of packaging waste on the environment. These products are often recyclable, compostable, or reusable, making them a more eco-friendly option. Sustainable packaging balances the need for protection and branding with the responsibility to preserve resources for future generations.

Our sustainable packaging products include custom corrugated boxes, folding cartons, pouches, and a variety of stock options. Each product is designed with eco-friendly materials to help reduce environmental impact while meeting your packaging needs.

Corrugated Boxes

- Regular slotted Container (RSC)

- Half Slotted Container (HSC)

- Full Overlap (FOL)

- Roll End Tuck Top (RETT/Mailer)

- Additional Box Styles

- Corrugated Inserts

Folding Cartons

- Straight Tuck End (STE)

- Reverse Tuck End (RTE)

- Full Seal

- Auto Bottom

- Chipboard Inserts

Pouches

- Stand Up

- Lay Flat

- Gusseted

- Retort

- Block Bottom

- Sachets

- Additional Pouch Styles

Stock Packaging Products

- Corrugated Packaging

- Shipping Boxes

- Chipboard Packaging

- Edge Protectors

- Mailers (Kraft)

- Kraft Tape

- Kraft Paper

At Brown Packaging, we prioritize eco-friendly packaging solutions that help reduce environmental impact. Our commitment to green packaging ensures that we provide sustainable materials, allowing you to make responsible choices for your business and the planet.

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

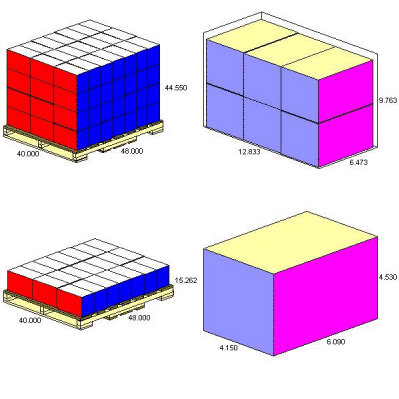

We provide packaging solutions designed to help reduce your carbon footprint through eco-friendly production, efficient shipping, and sustainable materials. From pallet optimization to energy-efficient manufacturing, our approach ensures that your packaging minimizes environmental impact at every stage.

Our custom structural design services allow us to minimize material use without compromising protection. By optimizing the design for strength and efficiency, we help you reduce excess packaging and the environmental costs associated with waste. Smarter packaging design means a lower carbon footprint overall.

With CAPE software, we optimize pallet configurations to maximize space and load efficiency. This results in fewer trips and lower fuel usage during transportation, reducing your carbon footprint. By making the most of every pallet, we help you achieve more eco-friendly logistics.

We offer digital samples, eliminating the need for multiple physical prototypes, which reduces waste and energy use in production. By creating virtual models, we help you save resources while speeding up the design process. This eco-friendly approach helps minimize the carbon footprint of packaging development.

We focus on eco-friendly production processes that minimize waste and reduce energy consumption. By using sustainable materials and optimizing manufacturing efficiency, we help lower the carbon footprint of your packaging. This commitment to sustainable production ensures a smaller environmental impact from the start.

Our lightweight and efficient packaging solutions help reduce transportation emissions by maximizing space and minimizing weight. By designing packaging that is easy to transport, we help your business cut down on fuel consumption and overall shipping costs, contributing to a reduced carbon footprint.

We design packaging with durability and reusability in mind, extending the useful life of each product. By creating packaging that can be used multiple times before disposal or recycling, we help reduce waste and conserve resources, contributing to a smaller environmental footprint.

We prioritize sourcing materials from local suppliers to reduce transportation distances and emissions. By keeping production and distribution close to home, we help cut down on the environmental impact associated with long-distance shipping. Local sourcing ensures a more sustainable and efficient supply chain.

We offer packaging made from eco-friendly, recyclable, and biodegradable materials that reduce reliance on virgin resources. By using sustainable materials, we help decrease the carbon emissions associated with material extraction and production. This ensures that your packaging has a smaller environmental impact from the very start.

Interested In Sustainable Packaging Solutions?

Discover the latest insights on sustainable packaging by exploring our blog, where we share tips and innovations to help businesses reduce their environmental impact. Stay informed about eco-friendly packaging solutions and learn how your company can make a difference through sustainability.

In shipping large quantities of goods, ensuring the safety and stability of pallet loads is paramount. Edge protectors play a vital role in protecting palletized shipments from damage during transportation and handling. This blog explores how edge protectors enhance the security of pallet loads, their types, and the benefits they bring to logistics and supply chains. What Are Edge Protectors? Edge protectors, also known as corner protectors, are sturdy materials placed along the edges of palletized loads to provide reinforcement and protection. Typically made from plastic, corrugated, or foam materials, edge protectors prevent damage to packaging and products during strapping, stacking, and transit. They come in various sizes, thicknesses, and shapes, such as L-shaped or flat, to suit different load configurations. Types of Edge Protectors Plastic Edge Protectors Material: High-density polyethylene (HDPE). Uses: Ideal for securing heavy pallet loads. Benefits: Strong and durable, resistant to moisture and impact, and reusable. Corrugated Edge Protectors Material: Sturdy corrugated board. Uses: Suitable for eco-conscious businesses or lighter palletized goods. Benefits: Lightweight, recyclable, and customizable in length and thickness. Foam Edge Protectors Material: Shock-absorbing foam. Uses: Best for fragile or sensitive products on pallets. Benefits: Provides superior cushioning against impacts and vibrations during transport. Benefits of Edge Protectors for Pallet Loads Enhanced Stability Edge protectors help secure straps tightly around palletized loads, reducing the risk of movement or shifting during transportation. This stability minimizes the likelihood of toppled pallets and damaged products. Prevents Strap Damage Tensioned straps can dig into packaging, causing tears or deformation. Edge protectors distribute the pressure evenly across the load, safeguarding both the packaging and the products inside. Improved Load Integrity By reinforcing the corners and edges of a pallet load, edge protectors prevent crushing and damage, particularly for cartons stacked at the bottom of the pallet. Reduced Shipping Costs Minimizing damage to goods lowers the risk of returns and replacements, reducing overall shipping expenses and improving profit margins. Streamlined Stacking and Storage Edge protectors maintain the structural integrity of stacked pallets, allowing for safe and efficient storage in warehouses or during transit. Enhanced Sustainability Corrugated edge protectors are biodegradable and recyclable, making them an eco-friendly choice for businesses aiming to reduce their environmental impact. Protection Against Legal Liability Properly secured pallet loads with edge protectors demonstrate due diligence in product safety, reducing the risk of legal disputes over damaged goods during transportation. Customization for Pallet Loads Edge protectors can be customized to fit the unique requirements of palletized shipments: Length and Thickness: Tailor edge protectors to match pallet dimensions and load weight. Materials: Choose foam for fragile products or plastic for heavier loads. Branding: Add logos or company branding for enhanced visibility and professional presentation. Conclusion Edge protectors are indispensable for protecting palletized goods during shipping, ensuring stability, reducing damage, and lowering costs. They provide a cost-effective solution to safeguard products, maintain load integrity, and enhance overall operational efficiency. Interested in stock or custom edge protectors for palletized loads? Contact Brown Packaging today to explore options tailored to your business needs. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Edge Protectors Facebook Twitter LinkedIn Pinterest Relevant Posts

A study published in September 2024 in Frontiers in Toxicology has identified 189 chemicals present in food packaging materials that are potential or confirmed mammary carcinogens, with 76 of these detected in human populations worldwide. These chemicals, commonly found in plastics and paper used for food packaging, pose significant health risks, prompting calls for regulatory action to eliminate them from packaging materials. Study Overview Researchers from the Food Packaging Forum conducted a comprehensive review of chemicals used in food contact materials (FCMs). They cross-referenced a list of 921 chemicals associated with breast cancer with substances known to migrate from FCMs. The study revealed that 189 potential breast carcinogens are present in food packaging, including: Per- and Polyfluoroalkyl Substances (PFAS): Used for their grease-resistant properties in paper and cardboard packaging (source). Bisphenols (e.g., BPA): Found in plastic containers and linings of metal cans (source). Phthalates: Added to plastics to increase flexibility (source). The study also highlighted that 76 of these chemicals have been detected in human biomonitoring studies, indicating widespread exposure (study details). Implications for Packaging Buyers The presence of carcinogenic chemicals in food packaging materials has significant implications for packaging buyers: Regulatory Compliance: Anticipate stricter regulations limiting or banning the use of certain chemicals in food packaging. Consumer Safety: Growing consumer awareness of health risks associated with packaging materials may influence purchasing decisions. Supply Chain Adjustments: Sourcing safer alternative materials may require changes in suppliers and manufacturing processes. Recommendations for Packaging Buyers To mitigate health risks and align with potential regulatory changes, packaging buyers should consider the following actions: Evaluate Current Materials: Conduct a thorough assessment of the chemicals present in existing packaging materials. Source Safer Alternatives: Explore and adopt materials free from identified carcinogens, such as PFAS-free paper (more info) or BPA-free plastics (learn more). Collaborate with Suppliers: Work closely with suppliers to ensure compliance with safety standards and to develop innovative, safer packaging solutions. Stay Informed on Regulations: Monitor legislative developments related to food packaging materials to ensure ongoing compliance. Conclusion The identification of nearly 200 chemicals in food packaging linked to breast cancer underscores the urgent need for the packaging industry to prioritize consumer health. By proactively adopting safer materials and staying abreast of regulatory changes, packaging buyers can play a crucial role in reducing health risks and fostering consumer trust. For more information, consult the Frontiers in Toxicology study (full study) or reach out to industry resources like the Food Packaging Forum (resource center). If you are interested in safe food packaging and are looking to become compliant with current regulations, then partner with Brown Packaging today to get started. References Food Packaging Forum. (2024). Comprehensive review of chemicals in food contact materials associated with breast cancer. Retrieved from Food Packaging Forum Frontiers in Toxicology. (2024). Identification of mammary carcinogens in food packaging materials. Retrieved from Frontiers in Toxicology U.S. Food and Drug Administration (FDA). (n.d.). Bisphenol A (BPA): Use in food contact application. Retrieved from FDA World Health Organization (WHO). (n.d.). Per- and polyfluoroalkyl substances (PFAS): Key facts. Retrieved from WHO Centers for Disease Control and Prevention (CDC). (n.d.). Phthalates and human health. Retrieved from CDC (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Food Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

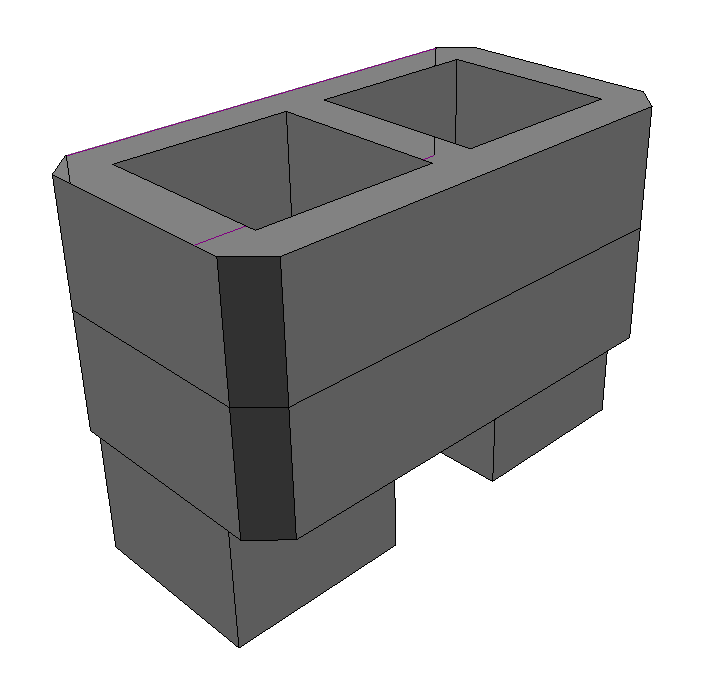

When working with thick foam materials in the packaging industry, it’s important to be aware of the natural outcomes of the die-cutting process—one of the most common being concavity. This phenomenon occurs when thick foam is cut into specific shapes, resulting in the sides of the die-cut parts appearing concave rather than perfectly straight. Understanding why this happens and how it impacts the final product is essential for anyone involved in packaging design and production. What is Concavity in Die-Cut Foam? Concavity refers to the inward curvature of the sides of a thick foam part after it has been die-cut. During the cutting process, the knife penetrates the foam, applying pressure unevenly across the material’s thickness. The top layer of foam experiences minimal compression as the knife begins its cut, while the middle and bottom layers undergo greater compression as the knife moves downward. This difference in compression causes the sides of the foam part to curve inward, creating a concave effect. Why Does Concavity Occur? The occurrence of concavity is directly related to the mechanics of the die-cutting process, particularly when dealing with thicker foam materials. As the die-cutting knife enters the foam, the pressure applied is not uniform across the entire thickness of the material. The initial entry of the knife into the top layer results in less compression, while the subsequent layers experience increasing levels of compression as the knife cuts deeper. This uneven pressure distribution is what leads to the concave sides. It’s crucial to recognize that concavity is not a flaw but rather a natural characteristic of die-cutting thick foam. Understanding this aspect of the process allows for better planning and consideration when designing and producing packaging solutions that utilize thick foam materials. Considerations for Packaging Design When designing packaging that involves thick foam die-cut parts, it’s important to account for the potential concavity of the sides. This feature should be factored into the overall design to ensure that it does not interfere with the functionality or appearance of the packaging. In most cases, concavity does not impact the performance of the foam part, but it’s essential to be aware of its presence during the design phase. For applications where the appearance or specific fit of the foam is critical, additional measures may need to be taken to address or minimize concavity. However, for many packaging solutions, the concave sides of die-cut foam parts will not affect their ability to provide cushioning, protection, or support. Conclusion Concavity in thick foam die-cut parts is a natural and expected outcome of the die-cutting process. Understanding this phenomenon is key to making informed decisions during the packaging design and production process. By accounting for concavity in your designs and recognizing its impact—or lack thereof—on the final product, you can ensure that your packaging solutions are both effective and reliable. As with any aspect of packaging production, being informed and prepared is essential to achieving the best possible results. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Foam Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts