Sustainable Packaging

Explore our sustainable packaging products, including corrugated boxes, folding cartons, pouches, and stock packaging options. We offer eco-friendly materials and a variety of print and ink choices to fit your packaging needs. Choose from solutions designed to support sustainability and meet your business requirements.

Sustainable packaging refers to the use of materials and design methods that minimize environmental impact. This can include using recyclable or biodegradable materials, reducing excess packaging, and opting for renewable resources like paper, kraft, or corrugated materials. The goal is to reduce waste, conserve energy, and lessen the overall carbon footprint of packaging.

By choosing sustainable packaging, businesses help limit the negative effects of packaging waste on the environment. These products are often recyclable, compostable, or reusable, making them a more eco-friendly option. Sustainable packaging balances the need for protection and branding with the responsibility to preserve resources for future generations.

Our sustainable packaging products include custom corrugated boxes, folding cartons, pouches, and a variety of stock options. Each product is designed with eco-friendly materials to help reduce environmental impact while meeting your packaging needs.

Corrugated Boxes

- Regular slotted Container (RSC)

- Half Slotted Container (HSC)

- Full Overlap (FOL)

- Roll End Tuck Top (RETT/Mailer)

- Additional Box Styles

- Corrugated Inserts

Folding Cartons

- Straight Tuck End (STE)

- Reverse Tuck End (RTE)

- Full Seal

- Auto Bottom

- Chipboard Inserts

Pouches

- Stand Up

- Lay Flat

- Gusseted

- Retort

- Block Bottom

- Sachets

- Additional Pouch Styles

Stock Packaging Products

- Corrugated Packaging

- Shipping Boxes

- Chipboard Packaging

- Edge Protectors

- Mailers (Kraft)

- Kraft Tape

- Kraft Paper

At Brown Packaging, we prioritize eco-friendly packaging solutions that help reduce environmental impact. Our commitment to green packaging ensures that we provide sustainable materials, allowing you to make responsible choices for your business and the planet.

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

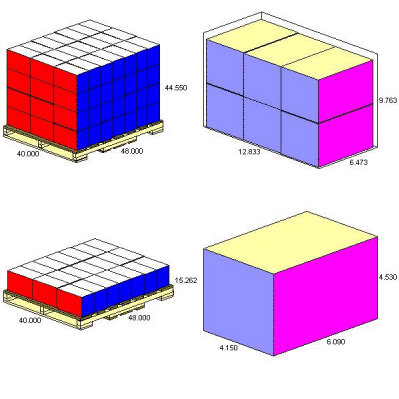

We provide packaging solutions designed to help reduce your carbon footprint through eco-friendly production, efficient shipping, and sustainable materials. From pallet optimization to energy-efficient manufacturing, our approach ensures that your packaging minimizes environmental impact at every stage.

Our custom structural design services allow us to minimize material use without compromising protection. By optimizing the design for strength and efficiency, we help you reduce excess packaging and the environmental costs associated with waste. Smarter packaging design means a lower carbon footprint overall.

With CAPE software, we optimize pallet configurations to maximize space and load efficiency. This results in fewer trips and lower fuel usage during transportation, reducing your carbon footprint. By making the most of every pallet, we help you achieve more eco-friendly logistics.

We offer digital samples, eliminating the need for multiple physical prototypes, which reduces waste and energy use in production. By creating virtual models, we help you save resources while speeding up the design process. This eco-friendly approach helps minimize the carbon footprint of packaging development.

We focus on eco-friendly production processes that minimize waste and reduce energy consumption. By using sustainable materials and optimizing manufacturing efficiency, we help lower the carbon footprint of your packaging. This commitment to sustainable production ensures a smaller environmental impact from the start.

Our lightweight and efficient packaging solutions help reduce transportation emissions by maximizing space and minimizing weight. By designing packaging that is easy to transport, we help your business cut down on fuel consumption and overall shipping costs, contributing to a reduced carbon footprint.

We design packaging with durability and reusability in mind, extending the useful life of each product. By creating packaging that can be used multiple times before disposal or recycling, we help reduce waste and conserve resources, contributing to a smaller environmental footprint.

We prioritize sourcing materials from local suppliers to reduce transportation distances and emissions. By keeping production and distribution close to home, we help cut down on the environmental impact associated with long-distance shipping. Local sourcing ensures a more sustainable and efficient supply chain.

We offer packaging made from eco-friendly, recyclable, and biodegradable materials that reduce reliance on virgin resources. By using sustainable materials, we help decrease the carbon emissions associated with material extraction and production. This ensures that your packaging has a smaller environmental impact from the very start.

Interested In Sustainable Packaging Solutions?

Discover the latest insights on sustainable packaging by exploring our blog, where we share tips and innovations to help businesses reduce their environmental impact. Stay informed about eco-friendly packaging solutions and learn how your company can make a difference through sustainability.

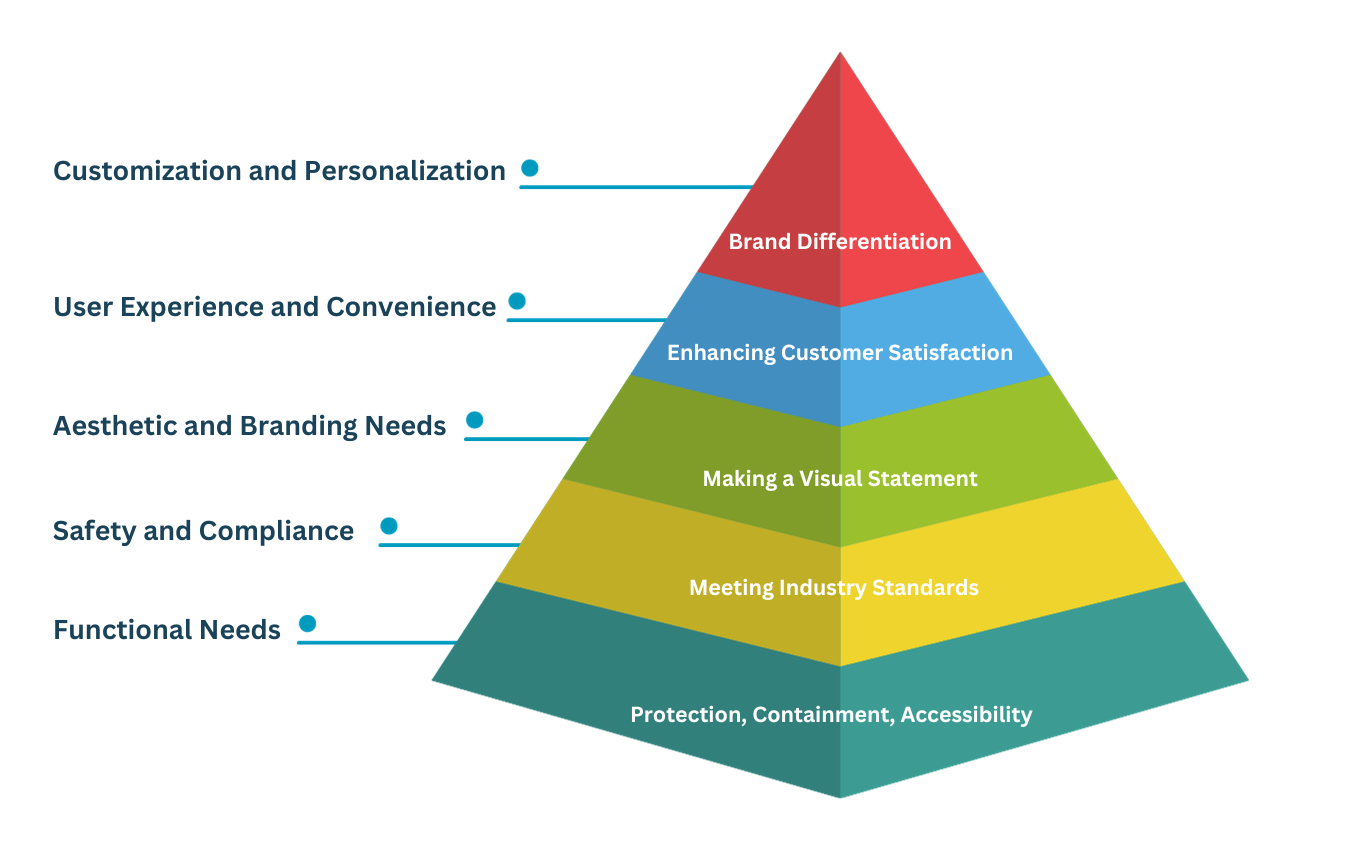

When it comes to packaging, it’s easy to dismiss it as merely a wrapper for the product. However, packaging serves a crucial role in not only protecting the product but also influencing consumer perception and purchase decisions. In the world of custom packaging, understanding the hierarchy of needs is essential to create packaging that not only satisfies basic requirements but also elevates your brand. Let’s dive into this packaging hierarchy and explore how it can impact your business. Functional Needs: The Foundation of Packaging At the base of the packaging hierarchy lie the functional needs. These are the fundamental requirements that packaging must meet to serve its primary purpose effectively. Without these basic functions, packaging would fail in its essential role. Protection: Packaging should safeguard the product from damage during transportation, handling, and storage. It’s the first line of defense against the rigors of the supply chain. Containment: A well-designed package securely holds the product, preventing spillage, breakage, or leakage. It ensures that the product reaches the customer intact. Accessibility: Packaging should facilitate easy access to the product. Consumers shouldn’t struggle to open or close the package, ensuring a seamless user experience. Safety and Compliance: Meeting Industry Standards Once functional needs are met, safety and compliance considerations come into play. Adherence to regulations and safety standards is vital for both consumer safety and the brand’s reputation. Regulatory Compliance: Packaging must conform to relevant laws and regulations, including labeling requirements and environmental standards. Non-compliance can lead to legal issues and damage your brand’s image. Product Safety: Beyond legal requirements, the packaging materials themselves should not pose any safety risks to consumers. This includes considerations like avoiding toxic substances in packaging. Aesthetic and Branding Needs: Making a Visual Statement Moving up the hierarchy, we encounter the aesthetics and branding aspects of packaging. These elements contribute to the visual appeal of your product and its ability to communicate your brand identity. Visual Appeal: Your packaging should be visually attractive. Colors, graphics, and design should align with your brand’s image and resonate with your target audience. Information: Effective packaging communicates essential product information, usage instructions, and branding elements clearly. It helps consumers make informed choices and reinforces your brand. User Experience and Convenience: Enhancing Customer Satisfaction Beyond aesthetics, the user experience and convenience are paramount. Packaging should enhance the overall customer experience and convenience in using the product. Ease of Use: Packaging should be user-friendly, allowing customers to open and close it without frustration. A pleasant unboxing experience can leave a lasting positive impression. Eco-Friendliness: In today’s environmentally conscious world, eco-friendly packaging is a priority. Sustainable materials and responsible design can appeal to eco-conscious consumers. Customization and Personalization: Setting Your Brand Apart At the pinnacle of the packaging hierarchy is customization and personalization. Custom packaging solutions can set your brand apart and create a unique identity in the market. Tailored Solutions: Custom packaging designs cater to specific products and consumer preferences. They can be tailored to fit various product shapes and sizes. Brand Differentiation: In a crowded marketplace, custom packaging helps your brand stand out. It reinforces brand recognition and builds a loyal customer base. In conclusion, the hierarchy of needs in custom packaging serves as a roadmap for designing packaging that not only meets basic requirements but also elevates your brand. By starting with the foundation of functionality and working your way up to aesthetics and customization, you can create packaging that not only protects your product but also enhances its appeal and strengthens your brand identity. Remember, in the world of packaging, meeting basic needs is just the beginning of a beautiful branding journey. If you are interested in custom packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging is not merely a practical aspect of shipping; it’s also a statement about your brand’s commitment to quality and protection. When it comes to safeguarding your products during transportation, two commonly utilized materials for packaging inserts are corrugated and foam. In this detailed exploration, we will delve into the nuances that set these two options apart, helping you make an informed choice that aligns with your specific packaging needs. Corrugated Inserts Material Composition: Corrugated inserts, the stalwarts of the packaging world, owe their strength to the clever combination of three layers – an inner layer, an outer layer, and a fluted middle layer. This design ensures remarkable durability while maintaining a lightweight profile. Customization: The versatility of corrugated inserts is impressive. They can be intricately die-cut into various shapes and sizes, perfectly tailored to cradle your products. Cost-Effectiveness: If budget constraints are a concern, corrugated inserts offer a cost-effective solution, ensuring that your products are protected without breaking the bank. Eco-Friendly: With environmental consciousness on the rise, corrugated cardboard stands out as an eco-friendly choice. Its recyclability and biodegradability resonate well with eco-conscious customers. Protection: Corrugated inserts provide reliable protection against common shipping hazards like impacts and vibrations, making them ideal for products with moderate fragility. Stackability: Their stackable nature makes corrugated inserts efficient for storage, a feature that can significantly optimize warehouse space. Foam Inserts Material Composition: Foam inserts come in various formulations, including polyethylene (PE) foam, polyurethane (PU) foam, and ethylene-vinyl acetate (EVA) foam. These foams are revered for their cushioning properties. Customization: Like their corrugated counterparts, foam inserts can be precision-cut to match the unique contours and shapes of your products, ensuring a snug and secure fit. Superior Cushioning: Foam inserts are the champions of cushioning, excelling in cradling delicate items with an extra layer of protection. They are often the go-to choice for high-value electronics, precision instruments, and delicate medical devices. Density Options: The availability of various foam densities allows you to select the level of cushioning that precisely matches your product’s fragility and weight. Reusability: Foam inserts, being more durable, can be reused multiple times. This can be a cost-effective option for businesses dealing with returns or shipments to multiple destinations. Weight: It’s worth noting that foam inserts are more bulkier than corrugated inserts, which may contribute to the overall space required of the package and potentially affect shipping costs, especially for international deliveries. Conclusion In the packaging world, one size does not fit all. Your choice between corrugated inserts and foam inserts hinges on several factors, including the fragility of your products, budget constraints, and your commitment to environmental sustainability. Sometimes, a hybrid approach works best – employing corrugated inserts for the outer packaging and foam inserts within to offer a comprehensive solution that marries cost-effectiveness and superior cushioning. Remember, your packaging reflects your brand’s dedication to quality, so choose wisely to ensure your products arrive safely and leave a lasting impression on your customers. If you are interested in corrugated, foam or other packaging inserts, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Foam Folding Carton Packaging Protection Retail Rigid Box Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Packaging Inserts Facebook Twitter LinkedIn Pinterest Relevant Posts

In the realm of product management, the relationship between packaging and storage is often overlooked, yet it is a critical aspect of operational efficiency and cost-effectiveness. Striking the right balance between these two can significantly impact a business’s bottom line. This blog post explores strategies for balancing storage needs with effective packaging, ensuring that your business maximizes space without compromising on packaging quality. Understanding the Importance of Balance The challenge lies in optimizing packaging to protect and enhance the product while also considering how it fits into storage facilities. Overly bulky packaging can consume excessive storage space, leading to higher costs, whereas insufficient packaging can lead to product damage. Assessing Your Current Packaging and Storage Situation Begin by evaluating your current packaging designs and storage setup: Analyze Packaging Size and Design: Determine if your current packaging is space-efficient and if not, identify areas for improvement. Storage Utilization Review: Assess how effectively you are using your existing storage space. Are there gaps or overcrowded areas? Optimizing Packaging for Storage Efficiency Design for Space Efficiency: Consider redesigning packaging to fit more compactly into storage spaces. Utilize designs that are stackable and easy to handle. Material Considerations: Explore materials that provide adequate protection but are also more flexible or compressible for storage. Modular Packaging: Implement packaging that can be easily adjusted or reconfigured to accommodate different storage spaces or product sizes. Incorporating Smart Storage Solutions Vertical Storage Strategies: Utilize vertical space effectively, especially if floor space is limited. Shelving and stacking systems can maximize vertical storage. Just-in-Time Inventory: Implement just-in-time (JIT) inventory practices to reduce the need for large storage spaces. Automated Storage Systems: Consider investing in automated storage solutions that can optimize space utilization and improve retrieval efficiency. Balancing Safety with Space Optimization Safety Considerations: Ensure that in your pursuit of space optimization, the safety and integrity of the products are not compromised. Emergency Stock Storage: Keep a emergency stock to manage fluctuations in demand without overburdening your storage with excess packaging materials. Evaluating Packaging and Storage Costs Cost-Benefit Analysis: Regularly conduct a cost-benefit analysis of your packaging and storage. This includes assessing the costs of potential packaging redesigns versus the savings in storage space and handling. Long-term Savings: Consider the long-term savings that can be achieved through more efficient packaging and storage solutions, even if they require upfront investment. Environmental Considerations Sustainability in Packaging and Storage: Adopt sustainable practices in both packaging and storage. This can include using recyclable materials and implementing energy-efficient storage systems. Reducing Waste: Efficient packaging and storage can significantly reduce waste, contributing to a more environmentally friendly operation. Leveraging Technology for Better Coordination Inventory Management Software: Use technology to better coordinate between packaging and storage. Inventory management systems can provide real-time data to optimize both. Collaboration Tools: Use collaborative tools to ensure seamless communication between packaging designers, warehouse managers, and logistics teams. If you are looking to maximize your packaging efficiency while balancing your storage space, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts