Stock Packaging

We supply businesses with a wide selection of essential packaging, shipping, and warehouse supplies. Get any standard packaging product by dimension or style from boxes, tubes, tapes, labels, and more. If you are unsure on what type of packaging you will need, then contact us for an expert consultation.

Stock packaging refers to pre-made, ready-to-ship packaging solutions like corrugated boxes, mailers, and protective materials that are designed to meet a wide range of standard needs across shipping, retail, and storage. Unlike custom packaging, stock options offer quick availability and reliable protection without the need for extensive design or production time, making them ideal for businesses needing efficient, high-quality solutions with fast lead times.

At Brown Packaging, we focus on providing durable, performance-driven stock packaging that supports our clients’ operational needs. Our stock products are sourced to ensure consistent quality and cost-effectiveness, offering a practical solution to keep operations running smoothly and on schedule. With an emphasis on reliability, we help our clients quickly access packaging solutions that meet their specific needs while maintaining quality across every order.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about custom packaging by reading our blog posts on new and trending topics.

Stretch film is a fundamental component in packaging, crucial for securing products on pallets for safe storage and transportation. This versatile plastic wrapping material is used worldwide by businesses of every type to protect and stabilize cargo during transit and in warehouses. Understanding the different types of stretch film and their specific applications is essential for optimizing packaging operations and reducing costs. What You Need To Know About Stretch Film Stretch film is designed to cling tightly to items, providing a secure overwrap that protects them from dust, moisture, and movement. Let’s dive into the details of the extrusion process, types of stretch film, and practical applications to help you make an informed decision when choosing the right stretch film for your needs. Extrusion Process The extrusion process is crucial in stretch film manufacturing, involving the heating or compression of resin to achieve the desired viscosity. This resin is then formed into a plastic layer through either a cast or blown extrusion process. Cast Stretch Film Cast stretch film is produced by melting resin and pushing it through a flat die onto chilled rollers, where it solidifies. This method creates a clear, glossy film with excellent cling and quiet unwind properties. Advantages of Cast Stretch Film: Good for securing pallet loads with smooth and straight edges (A and B loads). Transparent finish that makes it easier to see merchandise, product information, directions, and barcodes. Low noise when wrapping the pallets. Self-adhering properties. Available in single or double side cling (sticky). Medium puncture resistance. Easy to apply. Cheaper alternative compared to blown film. Disadvantages of Cast Stretch Film Not as strong as blown film in holding merchandise. Less memory and more prone to tear than blown film. Blown Stretch Film Blown stretch film is made by extruding melted plastic through an annular slit die, followed by blowing the molten tube up with air to form a thin film. This process results in a film that is strong, puncture-resistant, and has a higher degree of memory. Advantages of Blown Stretch Film: Good for securing pallets with pointed or sharp edges (C- loads). High resistant to tears and punctures Provides a higher carrying and holding capacity High level of memory once stretched Disadvantages of Blown Stretch Film Makes noise when wrapping the pallets Not as clear as cast film More expensive than cast Types of Stretch Film Conventional Stretch Film This is the standard film used for a variety of applications, versatile enough to handle regular load types. Engineered Stretch Film Engineered films are designed with advanced polymers to offer better performance with less material, ideal for reducing waste and improving load stability with less film. Pre-stretched Stretch Film Pre-stretched films are extended close to their ultimate break point prior to being wound onto rolls. This film is lighter and easier to apply, reducing fatigue for operators and material usage. Application Methods Hand Rolls Hand rolls are used for manual application, suitable for businesses that wrap fewer than 50 pallets per day. They are portable and do not require machinery, making them accessible for smaller operations. Machine Rolls Machine rolls are used with automatic or semi-automatic pallet wrapping machines. These are suitable for high-volume environments, providing consistent wrapping and reducing labor costs. Thickness and Additives The thickness of stretch film is typically measured in gauges, with a variety of specifications available to suit different load types and handling conditions. Additives can be incorporated into the film to confer additional properties such as UV resistance, anti-static behavior, or color tinting, enhancing functionality and safety. Hand Rolls Machine Rolls Film With Additives Summary: The Importance of Choosing the Right Stretch Film Selecting the right type of stretch film is vital for effective product protection and operational efficiency. By understanding the different types and their specific benefits, businesses can significantly reduce material waste, enhance cargo security, and optimize costs. Whether you’re wrapping a few pallets a day by hand or managing a large-scale distribution center, the appropriate stretch film can make a significant difference in your packaging operations. For detailed advice and options on stretch films, consider reaching out to packaging experts like Brown Packaging, who can provide tailored solutions based on your specific needs and industry requirements. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Folding Carton Display Packaging Rigid Box Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Stretch Film Facebook Twitter LinkedIn Pinterest Relevant Posts

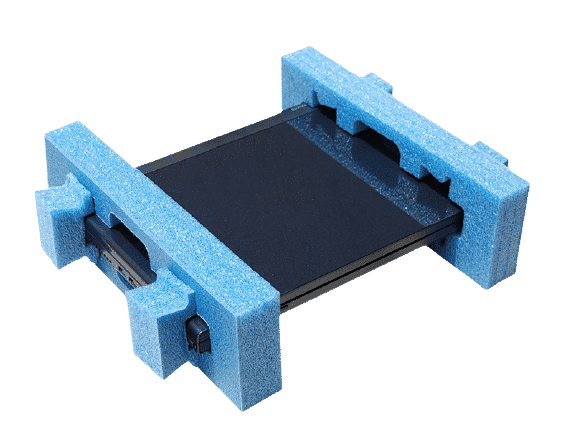

Packaging foam is essential for protecting products against shocks, vibrations, and other potential damages during transportation and storage. Understanding the different types of packaging foam available can help you choose the most suitable option based on your specific needs. This guide covers a variety of foam types, including the primary options—polyurethane, polyethylene, and expanded polystyrene (EPS)—and introduces additional varieties, each with unique properties and applications. Overview of Major Foam Types Polyethylene Polyurethane Expanded Polystyrene Polyethylene Foam (PE) Polyethylene foam is a closed-cell foam known for its durability and versatility. It’s made by heating and molding polymer compounds into millions of tiny bubbles, all sealed off from each other. Benefits: Chemical and Moisture Resistance: Highly resistant to chemicals and moisture. Durability: Offers excellent vibration and compression protection. Versatility: Customizable in multiple densities and colors with additives like fire retardants and anti-static agents. Fabrication Flexibility: Easily processed and fabricated into various shapes. Disadvantages: Environmental Impact: Challenges in recycling and potential toxicity when burned. Cost: More time-consuming and costly to fabricate compared to other materials. Applications: Used in industries such as electronics, medical, and construction for end caps, box liners, and protective blocks. Polyurethane Foam Polyurethane foam is an open-cell foam that is flexible and known for its excellent cushioning properties. Benefits: Cushioning Properties: Superior for protecting delicate items. Lightweight: Reduces shipping costs. Customization: Available in multiple colors and easily laminated. Thermal Insulation: Suitable for temperature-sensitive shipments. Disadvantages: Flammability: Emits toxic gases when burned. Odor: May not be suitable for odor-sensitive applications. Durability: Shorter shelf-life than closed-cell foams. Applications: Commonly used in protective packaging for electronics, medical devices, and specialty packaging designs. Expanded Polystyrene (EPS) EPS is a lightweight, molded, closed-cell foam, often referred to by its brand name, Styrofoam. Benefits: Cost-Effectiveness: Economical for various applications. Lightweight and Strong: Provides excellent protection without significant weight. Insulation: Good thermal resistance. Moisture Resistance: Does not absorb water, ideal for humid environments. Disadvantages: Environmental Concerns: Difficult to recycle and not eco-friendly. Durability: Brittle and degrades under UV exposure. Applications: Widely used in shipping containers for food and medical supplies and protective packaging. Additional Types of Packaging Foam Ethylene-Vinyl Acetate (EVA) EVA foam is known for its rubber-like softness and flexibility, making it ideal for applications requiring a smooth and soft texture. Benefits: Shock Absorption: Excellent for sports equipment and luxury packaging. Water Resistance: Does not absorb water, enhancing its durability. Chemical Resistance: Resists oils and greases, suitable for industrial applications. Applications: Commonly used for padding in equipment, sports gear, and high-end retail packaging. Cross-Linked Polyethylene Foam This type of foam offers superior durability and is ideal for requiring fine, aesthetic finishes. Benefits: Smooth Surface: Provides a clean, professional look. High Durability: Resistant to tearing and punctures. Thermal Stability: Maintains properties over a wide temperature range. Applications: Used for medical devices, automotive interiors, and cases for delicate instruments. Cross-Linked Polyethylene Conclusion: Different Types of Packaging Foam The variety of packaging foams available offers businesses a wide range of options to protect and enhance their products. From the versatile polyethylene and cushioning polyurethane to the economical EPS and specialized foams like EVA and cross-linked polyethylene, each type provides unique benefits suited to different packaging needs. Understanding these options will help you select the best foam type for your specific product protection, branding, and sustainability goals. If you are interested in exploring custom packaging foam solutions tailored to your products, consider partnering with a specialist like Brown Packaging to navigate the selection process and optimize your packaging strategy effectively. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Foam Facebook Twitter LinkedIn Pinterest Relevant Posts

In today’s competitive market, differentiation is key. Custom packaging offers a strategic advantage, enabling businesses to tailor their packaging to specific product needs, brand identity, and consumer preferences. Here’s an exploration of the numerous benefits that custom packaging can bring to your business, from enhancing brand visibility to optimizing costs and improving customer experience. Here are 8 reasons to invest in custom packaging: Decreases Your Overhead Improves Storage Efficiency Increase Sales Improve Brand Awareness Better Representation of Your Brand Higher Perceived Value of Products Maximize the Consumer Experience Meet any Requirements Decreases Your Overhead Investing in custom packaging can lead to substantial cost savings over time. By tailoring the design to your specific products, you reduce material waste and improve packing efficiency. This optimization extends to logistics, where custom dimensions can mean more product per shipment, reducing the frequency and cost of deliveries. Moreover, custom packaging can be designed to minimize damage during transit, decreasing the need for replacements and refunds. Improves Storage Efficiency Custom-designed packaging can revolutionize how you use space in your storage facilities and retail environments. By creating packages that are collapsible, stackable, or tailored to fit unique storage configurations, you can maximize the use of available space, reducing storage costs. This is particularly beneficial for businesses with limited warehouse space or those looking to reduce rental costs. Increase Sales Attractive and unique packaging designs can capture the attention of potential buyers, significantly increasing the chances of purchase. Custom packaging allows for the integration of eye-catching graphics, innovative shapes, and enhanced functionality that can make your product stand out on the shelves. This not only helps in attracting new customers but also in retaining interest among existing customers by keeping the product presentation fresh and engaging. Improve Brand Awareness Custom packaging acts as a direct reflection of your brand’s values and quality. Whether your brand emphasizes luxury, eco-friendliness, innovation, or user-friendliness, the packaging can be crafted to convey these traits effectively. For example, using recycled materials can emphasize a commitment to sustainability, while premium materials and finishes can enhance the luxury feel. Better Representation of Your Brand Custom packaging acts as a direct reflection of your brand’s values and quality. Whether your brand emphasizes luxury, eco-friendliness, innovation, or user-friendliness, the packaging can be crafted to convey these traits effectively. For example, using recycled materials can emphasize a commitment to sustainability, while premium materials and finishes can enhance the luxury feel. Higher Perceived Value of Products The quality and design of packaging significantly influence how consumers perceive the value of the product inside. High-quality, well-designed packaging suggests a high-quality product, allowing you to potentially command a higher price point. Custom packaging creates an unboxing experience that can turn routine purchases into memorable moments, enhancing customer satisfaction and perceived product value. Maximize the Consumer Experience Custom packaging goes beyond aesthetics; it enhances the user experience through added functionality. Features such as easy-open tabs, resealable closures, and ergonomic designs can make your products more accessible and enjoyable to use. This attention to the consumer’s needs can greatly enhance satisfaction and encourage repeat purchases. Meet Any Requirements Custom packaging can be specifically designed to meet industry regulations and standards, which is critical for products requiring compliance with safety, handling, and environmental regulations. This ensures that your products are not only well-protected but also legally compliant, avoiding potential legal issues and enhancing consumer trust in your brand. Summary: Why You Should Invest In Custom Packaging The strategic investment in custom packaging provides numerous benefits from operational efficiencies to marketing advantages. By tailoring packaging specifically to your product and brand needs, you can enhance visual appeal, increase functionality, and convey your brand story more effectively. In an era where packaging often serves as a consumer’s first touchpoint with a product, custom packaging is not just advisable; it’s essential. For businesses looking to leverage these benefits, working with a skilled packaging provider like Brown Packaging can ensure that your packaging solutions are not only innovative and appealing but also cost-effective and aligned with your strategic goals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Folding Carton Display Packaging Rigid Box Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts