Stock Packaging

We supply businesses with a wide selection of essential packaging, shipping, and warehouse supplies. Get any standard packaging product by dimension or style from boxes, tubes, tapes, labels, and more. If you are unsure on what type of packaging you will need, then contact us for an expert consultation.

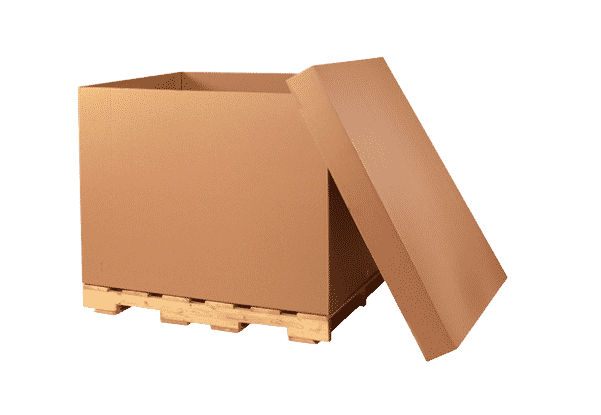

Stock packaging refers to pre-made, ready-to-ship packaging solutions like corrugated boxes, mailers, and protective materials that are designed to meet a wide range of standard needs across shipping, retail, and storage. Unlike custom packaging, stock options offer quick availability and reliable protection without the need for extensive design or production time, making them ideal for businesses needing efficient, high-quality solutions with fast lead times.

At Brown Packaging, we focus on providing durable, performance-driven stock packaging that supports our clients’ operational needs. Our stock products are sourced to ensure consistent quality and cost-effectiveness, offering a practical solution to keep operations running smoothly and on schedule. With an emphasis on reliability, we help our clients quickly access packaging solutions that meet their specific needs while maintaining quality across every order.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about custom packaging by reading our blog posts on new and trending topics.

Packaging plays a pivotal role in the world of snacks, influencing everything from freshness and shelf life to branding and consumer appeal. With a multitude of packaging materials available, selecting the right one for your snacks is a critical decision that affects both product quality and market success. In this comprehensive guide, we’ll explore the various packaging materials suitable for snacks and delve into their benefits and considerations. Factors to Consider When Choosing Packaging Material Before delving into specific packaging materials, let’s examine the key factors to consider: Product Protection: The packaging material must protect snacks from external factors like moisture, air, light, and physical damage. Freshness and Shelf Life: Different materials offer varying levels of barrier protection, affecting the snacks’ freshness and shelf life. Brand Identity: Packaging contributes to brand recognition. The material’s appearance, texture, and print quality should align with your brand’s image. Eco-Friendliness: As sustainability gains prominence, choosing environmentally friendly materials is essential to minimize environmental impact. Cost: Packaging costs influence your product’s overall pricing strategy. Balancing quality and cost is crucial. Consumer Convenience: Packaging should be easy to open, resealable, and suitable for on-the-go consumption. Common Snack Packaging Materials Flexible Plastic Bags Benefits: Versatile, lightweight, and cost-effective. Offers excellent barrier properties against moisture and air. Considerations: Some plastic materials are not environmentally friendly. May lack a premium look for high-end products. Paperboard Cartons Benefits: Sturdy, printable, and environmentally friendly. Ideal for branding and visual appeal. Considerations: Limited barrier protection compared to other materials. Not suitable for snacks requiring a longer shelf life. Aluminum Foil Benefits: Provides exceptional barrier protection against moisture, light, and oxygen. Ensures prolonged freshness. Considerations: Relatively higher cost. Limited recyclability due to composite materials. Metal Cans Benefits: Offers excellent protection, ideal for snacks prone to breakage. Durable and visually appealing. Considerations: Heavier and costlier compared to other materials. Limited options for resealability. Stand-Up Pouches Benefits: Lightweight, space-efficient, and visually appealing. Can incorporate resealable features for convenience. Considerations: Barrier properties vary based on materials used. Not ideal for all types of snacks. Biodegradable and Compostable Materials Benefits: Environmentally friendly, reducing plastic waste. Appeals to eco-conscious consumers. Considerations: May have limited barrier properties compared to traditional materials. Higher cost for some options. Paperboard Pouch (Plastic Films) Corrugated Matching Materials to Snack Types Different snacks have unique requirements that influence the ideal packaging material: Chips and Crisps: Air-tight packaging like foil bags or metal cans maintain crispiness. Cookies and Baked Goods: Paperboard cartons offer a balance between protection and branding. Fresh Fruit Snacks: Flexible plastic with resealable features preserves freshness. Nuts and Trail Mix: Barrier properties of foil pouches prevent spoilage. Chocolate and Candy: Aluminum foil provides protection against temperature changes. Granola Bars: Biodegradable materials align with health-conscious branding. Roll Stock Balancing Sustainability and Practicality As consumers demand eco-friendly options, brands are focusing on sustainable packaging solutions. However, it’s essential to strike a balance between sustainability and practicality. Biodegradable materials might be ideal for some products, while others require longer shelf life provided by traditional materials. If you are interested in snack packaging solutions, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Snack Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In the packaging industry, achieving the perfect balance between ensuring product safety and optimizing space is a complex yet vital goal. This blog post explores various strategies and considerations for businesses aiming to navigate this balance effectively. Understanding the Challenge The intricacies of packaging require a careful balance. While it’s crucial to protect the product, it’s equally important to design packaging that is space-efficient for storage and transportation. This balance impacts not only cost-effectiveness but also environmental sustainability. Prioritize Product Safety The first and foremost consideration in packaging should always be the safety of the product. Understanding the product’s vulnerability, selecting quality materials, and conducting thorough testing are essential steps to ensure that the packaging adequately protects its contents. Design for Space Efficiency Effective packaging design maximizes space utilization without compromising safety. Compact and customized designs, along with modularity, can significantly enhance space efficiency in both storage and transportation. Implement Smart Packing Techniques Smart packing involves using strategic layering, padding, and multi-functional components to protect the product. These techniques aim to provide maximum safety with minimal material usage. Explore Advanced Materials and Technologies Innovative materials and technologies can offer improved protection with less bulk. The integration of smart sensors and advanced protective materials can revolutionize how products are packaged and monitored. Optimize for Storage and Transportation Optimizing packaging for storage and transportation involves designing for stackability and considering pallet optimization. This ensures that the packaging fits efficiently in warehouses and during transit, reducing transportation costs and space requirements. Conduct a Cost-Benefit Analysis Regularly assessing the costs associated with packaging materials and potential product damage is crucial. This analysis should weigh the costs of robust packaging against savings from reduced damage rates and improved space utilization. Sustainability Considerations Sustainable packaging is not just an environmental responsibility; it also contributes to the safety-space balance. Eco-friendly materials and strategies that minimize waste and promote recycling can play a significant role in this balance. Continuous Improvement and Adaptation Establishing a feedback loop for continuous data gathering and staying informed about industry trends are essential for adapting and improving packaging strategies. This approach ensures that packaging remains effective and efficient over time. Conclusion Balancing safety with space optimization in packaging is a dynamic and ongoing process. By focusing on these key areas and maintaining a flexible approach to packaging design and materials, businesses can achieve a packaging strategy that effectively protects their products while optimizing space and resources. If you are interested in packaging solutions, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated ESD Design Foam Packaging Printing Protection Retail Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

For industries seeking efficient solutions for material storage and transportation, corrugated gaylord boxes have emerged as a viable alternative to plastic totes and super sacks. These lightweight and cost-effective containers are not only environmentally friendly but also surprisingly versatile. Despite misconceptions about their single-use nature, gaylord boxes boast impressive durability and reusability, making them a favorite among businesses. In this guide, we’ll explore the diverse landscape of gaylord box sizes, shedding light on the various options available to manufacturers, retailers, and distributors alike. Versatility of Corrugated Gaylord Boxes Before we delve into the specifics of sizing, let’s revisit what makes Corrugated gaylord boxes a staple in the logistics world. Designed to accommodate bulk materials, these containers typically feature cubic or rectangular, ensuring easy access and secure storage. Corrugated Gaylord Box Sizes: An Overview Corrugated gaylord boxes span a range of sizes to suit diverse needs across industries. Sizing is typically expressed in inches, measuring length, width, and height. Below, we’ll detail some of the most common gaylord box sizes, along with their dimensions: Standard Corrugated Gaylord Size: 48 x 40 x 36″ The quintessential gaylord box, measuring 48 inches in length, 40 inches in width, and 36 inches in height. Often rectangular or octangular in shape with three to five walls, these boxes are the most prevalent, with up to 500-550 boxes fitting on a single trailer when properly palletized. The four and five wall variants of this size boast weight capacities ranging from 4,000 to 5,000 lbs. A standout feature is their compatibility with standard pallet dimensions, allowing for double stacking within trailers. This makes them ideal for metal, plastic, and electronic waste recycling. Moreover, these boxes can be bound to pallets, enabling multiple reuses and contributing to their resale value. Pallet Container: 40 x 40 x 40″ Similar in weight and carrying capacity to the standard 48 x 40 x 36″ corrugated gaylord box, this size measures 40 inches in each dimension. They offer versatility for internal logistics and transportation. The remarkable advantage is their ability to fit and stack on both 40 x 40 and 48 x 40 pallets. This flexibility, coupled with the capacity to hold 3,000 lbs in the four and five wall variants, positions them as a preferred choice for many users. Pallet Boxes: 40 x 30 x 30″ Measuring 40 inches in length, 30 inches in width, and 30 inches in height, these boxes vary in walls (2-5) and shapes (rectangular or octagonal). While their weight capacity depends on these factors, they are designed for lighter loads compared to the standard 48 x 40 x 36″ corrugated gaylord box. The typical 40 x 30 x 30″ box features 4 walls and holds around 1,200-1,500 lbs. Their advantage lies in their compatibility with standard 40 x 48 pallets, ensuring even stacking and easy transportation. Small Corrugated Gaylords: 36 x 36 x 36″ Catering to more compact needs, these boxes measure 36 inches in each dimension and typically feature three or four walls. Their smaller stature and lower wall count result in reduced weight and carrying capacities compared to the standard 48 x 40 x 36″ corrugated gaylord box. Weight capacities usually range from 1,000 to 1,200 lbs. While they may hold less weight, these boxes offer two distinct advantages: a higher quantity can fit onto a trailer, and they often come with a lower price per unit. Choosing the Perfect Fit: Factors to Consider Selecting the right corrugated gaylord box size involves a careful evaluation of several factors: Materials Volume: Assess the quantity of materials you intend to store or transport. Storage Space: Consider the available storage area or warehouse dimensions. Weight Capacity: Ensure the chosen size can safely accommodate the weight of your materials. Transportation: Account for any transportation constraints, such as truck dimensions or shipping regulations. Applications: Tailoring Sizes to Industries Different industries benefit from various corrugated gaylord box sizes: Agriculture and Manufacturing: Optimal sizes vary for packing produce or components. Uses mid to large sizes. Retail and Distribution: Choose sizes that streamline packaging and distribution processes. Uses small to mid sizes. Recycling Centers: corrugated gaylord boxes facilitate sorting recyclables of varying volumes. Use mid to large sizes. If you are interested in custom or stock corrugated gaylord boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated ESD Design Foam Packaging Printing Protection Retail Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Gaylord Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts