Home » Polyvinyl Chloride (PVC) in Packaging

Polyvinyl Chloride (PVC) in Packaging

Polyvinyl chloride, commonly known as PVC, is a widely used plastic in the packaging industry, celebrated for its versatility and durability. PVC’s unique properties make it an ideal choice for various packaging applications, utilizing its capability to be molded into rigid or flexible forms. In this blog, we’ll delve into the integral role of PVC in thermoforming, a process that transforms this adaptable material into innovative packaging solutions.

What is PVC?

PVC is a synthetic plastic polymer, commercially available in two basic forms: rigid and flexible. The rigid form of PVC is often used in construction for pipes and in windows and doors, while the flexible form is enhanced with plasticizers like phthalates, making it suitable for a wide range of packaging applications. Its intrinsic properties, such as resistance to environmental degradation, chemical stability, and durability, make it a staple in the packaging sector.

The Thermoforming Process of PVC

Thermoforming is a manufacturing process where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. PVC is particularly well-suited for this process due to its thermal stability and excellent moldability. Here’s how PVC is used in thermoforming for packaging:

Vacuum Forming

- Overview: This is the simplest form of thermoforming. Here, a sheet of plastic is heated and then stretched onto a single-surface mold. A vacuum is applied sucking the plastic sheet into the mold to form the desired shape.

- Applications: Vacuum forming is often used for packaging products that do not require intricate details or extreme precision, such as blister packaging and clamshell packaging which are prevalent in retail to securely package electronics, toys, and many consumer goods.

Pressure Forming

- Overview: This method involves applying pressure on the heated plastic sheet against the mold, in addition to the vacuum. This process allows for greater detail and texture in the molding.

- Applications: Pressure forming is used for packaging solutions that require finer details and textures. This method is suitable for high-quality blister packs and trays that need a more aesthetically pleasing appearance or functional components like snap-fits.

Twin-Sheet Forming

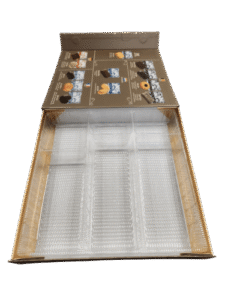

- Overview: Twin-sheet forming involves heating two plastic sheets simultaneously and then molding them to fuse together, creating a hollow structure.

- Applications: This technique is perfect for creating more robust and durable packaging solutions, like double-walled trays and cases that offer enhanced protection for transportation and storage.

Benefits of Using PVC for Packaging Thermoforming

- Durability: PVC offers excellent resistance to impact, which is crucial for protecting products during shipping and handling.

- Chemical Resistance: It is resistant to oils, greases, and other chemicals, making it ideal for packaging a wide variety of substances.

- Moisture Resistance: PVC’s non-porous nature ensures that the packaged goods are protected against moisture, enhancing the product’s shelf life.

- Cost-Effectiveness: PVC is a cost-effective material choice for bulk manufacturing of packaging materials due to its low raw material cost and efficient processing capabilities.

Applications of PVC in Packaging

PVC’s adaptability makes it suitable for a broad range of packaging needs:

- Medical Packaging: For sterile medical tools and devices, where cleanliness and visibility are paramount.

- Food Packaging: For food items where rigidity and resistance to grease are needed.

- Retail Packaging: Durable and clear packaging options like blister packs and clamshells that protect and display the product attractively.

For further details on how PVC can be integrated into your packaging strategy, or to explore the customization options available for your products, visit our frequently asked questions about polyvinyl chloride or contact our team at Brown Packaging, Inc.

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist highlights the critical areas buyers should review in 2026 when sourcing or redesigning subscription packaging. Branding and Unboxing Experience Seasonal or rotating graphics to keep unboxing fresh. Premium finishes such as foil, embossing, or unique die-cuts. Easy-open features like tear strips for convenience. Right-Sizing and Efficiency Reduce DIM charges with packaging tailored to product sizes. Use modular designs to cover multiple SKUs with fewer box sizes. Ensure packaging works with automation to speed fulfillment. Protection and Durability Inserts that prevent product shifting during transit. ISTA-tested designs to withstand vibration and drops. Moisture-resistant coatings for temperature-sensitive items. Sustainability Requirements FSC-certified corrugated or recycled substrates. Recyclable coatings or compostable options. Clear sustainability messaging to support consumer expectations. Cost Control SKU rationalization to limit unnecessary box variations. Material selection that balances protection and price. Supplier contracts that secure pricing for seasonal peaks. Packaging Solutions with Brown Packaging Brown Packaging designs subscription packaging that combines branding, protection, and sustainability. From FSC-certified corrugated to custom inserts, our solutions help buyers create packaging that builds loyalty and controls costs in 2026. Contact us to review your subscription packaging program. References Sustainable Packaging Coalition. (2023). Subscription Packaging and Consumer Insights. Retrieved from https://sustainablepackaging.orgForest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Ecommerce Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated customers. The key is balancing material use, box design, and supply chain efficiency so that savings do not come at the expense of protection. Where Packaging Costs Add Up Oversized boxes: Drive dimensional weight charges. Excess materials: Overuse of void fill and inserts. Complex SKU mix: Redundant sizes increase inventory costs. Inefficient freight: Poor palletization and stacking. Cost-Saving Strategies That Maintain Protection Right-sizing: Match box size to product dimensions to cut DIM charges and material use. Optimize corrugated grades: Switch to single- or double-wall where appropriate without compromising strength. Consolidate SKUs: Streamline packaging options to reduce inventory overhead. Efficient inserts: Replace foam or excess dunnage with engineered corrugated or molded pulp. Supplier contracts: Negotiate based on annual volumes, not just peak season orders. Testing Before Implementing Changes Use ASTM and ISTA protocols to ensure changes won’t increase product damage. Test for compression, vibration, and drop resistance. Run pilot shipments before scaling across the supply chain. Balancing Sustainability and Cost Eco-friendly doesn’t have to mean expensive: Use recyclable coatings to reduce plastic films. Choose corrugated designs that require less material while maintaining stacking strength. Highlight sustainable solutions in marketing to offset cost concerns. Packaging Solutions with Brown Packaging Brown Packaging helps companies lower costs while protecting products across the supply chain. From SKU rationalization to right-sized corrugated solutions, our team ensures packaging savings don’t compromise performance. Contact us to optimize your packaging program. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.Sustainable Packaging Coalition. (2023). Packaging Efficiency and Waste Reduction Report. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping, and automation create new challenges for packaging buyers. The right materials, testing, and design strategies are critical to protecting products while controlling costs. Why Damage Prevention Matters Financial losses: Damaged products increase replacement and freight costs. Customer impact: Poor delivery experience reduces loyalty and repeat sales. Sustainability: Returns and waste drive higher carbon footprints. Compliance: Retailers often impose penalties for damaged shipments. Common Causes of Product Damage Compression: Pallet stacking weakens boxes in transit. Vibration and shock: Long-haul shipping increases risk. Moisture exposure: Humidity and rain compromise corrugated performance. Poor right-sizing: Oversized boxes allow product movement inside. Strategies to Reduce Damage in 2026 Right-size packaging: Minimize empty space and movement. Material optimization: Choose the correct corrugated grade for load demands. Protective inserts: Molded pulp or engineered corrugated reduce shock. Moisture-resistant coatings: Defend against water and humidity. Automation-friendly design: Prevent jams that damage products on high-speed lines. Testing Protocols for Damage Prevention ISTA testing: Simulates vibration, drops, and compression. ASTM standards: Validate packaging strength and durability. Pilot shipments: Real-world trials confirm lab results. Packaging Solutions with Brown Packaging Brown Packaging designs solutions that minimize damage across today’s complex supply chains. From right-sized corrugated to ISTA-tested inserts, we help buyers protect products while reducing costs. Contact us to strengthen your packaging program. References ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.International Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer expectations. Understanding these trends helps companies stay competitive while aligning packaging programs with industry standards. Sustainability Becomes Non-Negotiable Greater use of recyclable and compostable substrates. Retailers pushing suppliers toward FSC-certified materials. Minimalist designs that reduce waste without losing impact. Smarter Packaging for Supply Chains Increased adoption of right-sizing to reduce freight costs. Boxes designed for automation and faster fulfillment. Stronger corrugated grades to withstand long e-commerce journeys. Enhanced Consumer Experience Custom graphics for seasonal campaigns and limited editions. Tear strips, resealable closures, and window cutouts for convenience. Premium finishes that elevate gift packaging at retail. Growth of Hybrid Packaging Formats Combining corrugated strength with folding carton graphics. Modular designs for multi-SKU and club store environments. Packaging engineered to serve both e-commerce and in-store needs. Compliance and Testing Standards Retailers demanding ISTA and ASTM testing for packaging durability. Supply chain audits on recyclability and sustainability claims. More pressure for transparent reporting on environmental impact. Retail Packaging Solutions with Brown Packaging Brown Packaging helps brands adapt to evolving retail packaging trends. From sustainable substrates to automation-friendly designs, our solutions balance branding, durability, and compliance for 2026. Contact us to prepare your packaging program for the year ahead. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Trends and Consumer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is essential for controlling costs, securing reliable supply, and meeting compliance requirements. Why Packaging Contracts Matter Cost stability: Protects against sudden raw material price spikes. Supply security: Ensures availability during peak demand. Quality control: Aligns suppliers with testing and compliance standards. Operational efficiency: Streamlines purchasing and reduces administrative burden. Key Terms Buyers Should Negotiate Volume commitments: Secure better pricing with accurate forecasts. Price adjustment clauses: Define when and how costs can change. Lead times and delivery windows: Avoid shortages and production delays. Testing and compliance: Require ISTA, ASTM, or FSC certification where applicable. Sustainability commitments: Ensure suppliers align with environmental goals. Risks of Weak Contracts Paying inflated prices during market fluctuations. Receiving inconsistent corrugated strength or print quality. Missed shipments leading to costly expedited freight. Difficulty meeting retailer or regulatory compliance. Best Practices for Buyers in 2026 Leverage data: Use past order history to negotiate realistic volumes. Dual sourcing: Maintain backup suppliers for risk management. Annual reviews: Reassess terms to reflect changes in demand and compliance. Collaborative approach: Treat suppliers as partners, not just vendors. Packaging Solutions with Brown Packaging Brown Packaging helps buyers secure strong supplier contracts that balance cost, quality, and supply chain reliability. Our partnerships and industry expertise ensure your packaging program is protected for 2026 and beyond. Contact us to discuss supplier solutions. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Fiber Box Association. (2024). Corrugated Packaging Market Outlook. Retrieved from https://www.fibrebox.orgSustainable Packaging Coalition. (2023). Supplier Standards for Sustainable Packaging. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to avoid costly fines, rejected shipments, or damaged customer relationships. Why Compliance Matters in 2026 Retail requirements: Major retailers demand FSC, ISTA, and sustainability certifications. E-commerce standards: Carriers enforce dimensional weight and package testing rules. Global trade: Export packaging must comply with ISPM 15, ASTM, and ISO guidelines. Consumer trust: Transparency in packaging claims impacts purchasing decisions. Key Compliance Areas for Buyers Material sourcing: FSC-certified corrugated and board for sustainability. Labeling standards: GS1-compliant barcodes and accurate product details. Durability testing: ISTA and ASTM protocols for drop, vibration, and compression. Sustainability regulations: Requirements for recyclable or compostable materials. Chemical restrictions: Compliance with FDA, EU, or state-specific standards. Common Compliance Challenges Keeping up with frequent regulatory changes. Managing multiple certifications across suppliers. Balancing compliance with cost-efficiency. Verifying supplier claims for sustainability. Best Practices for Staying Compliant Audit suppliers annually to confirm certification validity. Run internal packaging tests before scaling. Track regulatory updates for each region you ship to. Work with experienced partners who understand industry compliance. Packaging Solutions with Brown Packaging Brown Packaging helps buyers meet 2026 compliance standards with FSC-certified materials, ISTA-tested designs, and regulatory expertise. Our team ensures your packaging meets retailer, carrier, and sustainability requirements. Contact us to keep your program compliant. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgGS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » Polyvinyl Chloride (PVC) in Packaging

Effective packaging plays a crucial role in product presentation and protection across various industries. Among the many packaging options available, blister packaging stands out as a versatile and valuable choice. Blister packs find widespread use in sectors such as pharmaceuticals, electronics, toys, and consumer goods. In this comprehensive guide, we’ll delve into the top 10 reasons why blister packaging should be a strong consideration for your product packaging needs. Enhanced Product Visibility Reliable Protection from Contamination Tamper-Evident Features Extensive Customization Options Exceptional Durability Cost-Effective Solution Space Efficiency Sustainability Considerations Shelf-Life Extension Versatile Packaging Solution Enhanced Product Visibility Blister packaging excels in showcasing your product. Its transparent plastic shell offers a clear view of the item within. This visibility builds consumer trust and confidence as customers can precisely see the product they are purchasing, reducing the likelihood of misunderstandings or dissatisfaction. Reliable Protection from Contamination One of the primary advantages of blister packs is their superior protection against external contaminants. The sealed plastic shell encases the product securely, shielding it from dust, moisture, and handling. This ensures that your product remains clean and intact until it is opened by the end-user. Tamper-Evident Features Blister packaging can be designed to incorporate tamper-evident features, such as perforated edges or prominently printed warnings. These elements reassure customers that the product has not been tampered with, enhancing safety and trust in your brand. Extensive Customization Options Blister packs offer ample room for customization. You can tailor the packaging to precisely fit the shape and size of your product, allowing you to add branding elements, labels, or eye-catching graphics. This level of customization creates a unique and visually appealing presentation that sets your product apart. Exceptional Durability Blister packs are renowned for their durability. They can withstand the rigors of handling, transportation, and storage. The robust plastic shell resists tearing, ensuring that your products reach customers in excellent condition. Cost-Effective Solution Blister packaging is often a cost-effective choice, particularly for high-volume production. The efficiency of the packaging process and material options can help reduce overall packaging costs while maintaining quality. Space Efficiency Blister packs are space-efficient, making them ideal for retailers and businesses with limited shelf or storage space. The compact design allows for easy stacking and storage, optimizing space usage. Sustainability Considerations Blister packaging can be designed with sustainability in mind. Many blister pack materials are recyclable, contributing to eco-friendly packaging practices. By choosing sustainable options, you can reduce your environmental footprint and appeal to environmentally conscious consumers. Shelf Life Extension Blister packs can be designed to extend the shelf life of products that require protection from moisture, light, or oxygen. This is particularly crucial for industries such as pharmaceuticals and food, where product freshness and integrity are paramount. Versatile Packaging Solution Blister packaging’s versatility is one of its standout features. It is suitable for a wide range of products, spanning pharmaceuticals, cosmetics, small electronics, hardware, and more. Its adaptability and compatibility with diverse product types make it a popular choice across various industries. Blister packaging offers a multitude of advantages, making it an attractive and versatile option for product packaging. Its transparency, contamination protection, tamper-evident features, customization possibilities, durability, cost-effectiveness, and space efficiency are some of the key reasons businesses opt for blister packaging. Additionally, blister packs can contribute to sustainability goals, extend product shelf life, and accommodate a wide array of products. Whether you operate in the pharmaceutical, electronics, or consumer goods industry, exploring the benefits of blister packaging can enhance your product’s appeal, protection, and marketability. If you are interested in blister packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Blister packaging plays an indispensable role in various sectors, especially in the pharmaceutical, food, and consumer goods industries. It provides a user-friendly and secure mode of packaging, keeping products safe from contamination and damage. Over the years, technological advancements have greatly transformed the way blister packs are designed and produced, paving the way for increased efficiency, improved product preservation, and superior end-user experience. This blog will delve into the latest technological innovations in blister pack design and production. Personalized and Smart Packaging Customization and personalization are not just trends, but are becoming the norm in today’s competitive market. To meet this growing demand, blister pack producers are turning to advanced design software and production equipment that enable them to create tailor-made packaging solutions. For instance, 3D printing technology is increasingly used for prototyping personalized blister packs. This approach reduces the design-to-production time, as well as costs associated with traditional prototyping methods. In addition to personalization, smart packaging is also on the rise. It integrates various technologies such as RFID (Radio Frequency Identification) tags, QR codes, and NFC (Near Field Communication) chips to provide value-added features such as product tracking, authentication, and consumer engagement. Sustainable Packaging Innovations Given the growing awareness and regulations related to environmental protection, sustainability is becoming a key consideration in blister pack design. Several innovative technologies are being implemented to minimize the environmental impact of blister packaging. One of the most promising innovations is the development of biodegradable and compostable materials. For example, many companies are experimenting with plant-based polymers like PLA (Polylactic Acid), a renewable and compostable alternative to petroleum-based plastics. Additionally, the concept of mono-material blister packs is gaining traction, facilitating easier recycling by eliminating the need to separate different materials. Automation and Robotics in Production Automation and robotics have significantly enhanced the efficiency and accuracy of blister pack production. High-speed, automated blister packaging machines are becoming standard in the industry, capable of producing thousands of packs per hour with precision and consistency. These machines come with features such as automatic filling, sealing, and cutting. In addition, robotic systems are increasingly used in blister pack production lines for tasks such as loading and unloading, inspecting the quality of packs, and sorting and palletizing the finished products. These advancements not only improve productivity but also reduce the risk of human errors and enhance workplace safety. Advanced Sensing and Inspection Systems Quality assurance is crucial in blister pack production, especially in sensitive sectors like pharmaceuticals. Thanks to technological advancements, modern blister packaging machines are equipped with advanced sensing and inspection systems. These systems use machine vision technology, infrared, and ultrasonic sensors to detect any defects or inconsistencies in real-time, ensuring every pack leaving the production line meets the highest standards of quality and safety. Digitalization and Industry 4.0 The blister pack production industry is embracing digitalization and the principles of Industry 4.0. Technologies such as the Internet of Things (IoT), Big Data, and cloud computing are increasingly being used to collect and analyze data from production lines. This data-driven approach enables predictive maintenance, reduces downtime, and optimizes the overall production process. Furthermore, the use of digital twins – virtual replicas of physical systems – allows manufacturers to simulate and optimize their production processes before implementing them in the real world. This results in more efficient production, reduced waste, and quicker troubleshooting. Interested in blister packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Blister Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In our daily lives, we come across a plethora of pharmaceutical products, either in our personal capacity or via someone close to us. In this blog, we will delve into a significant yet frequently overlooked component of these products: blister packs. We will explore their utility, benefits, and why the pharmaceutical industry is heavily dependent on them. Understanding Blister Packs Before delving into the specifics of the pharmaceutical industry’s dependence on blister packs, let’s first understand what they are. A blister pack is a type of packaging produced by sealing a product in a plastic cavity or pocket, usually with a paper, corrugated, or foil backing. They’re commonly used for packaging pharmaceutical products, particularly pills, tablets, and capsules. Why Blister Packs? So, why does the pharmaceutical industry prefer blister packs over other packaging options? The simple answer is the versatility, protection, and convenience that blister packs offer. Protection and Preservation Blister packs are predominantly used because they protect the individual doses of medication. They offer a barrier to moisture, light, and oxygen, preserving the effectiveness of the drugs. The separation of each pill also prevents cross-contamination and ensures that the product remains tamper-evident until it reaches the end consumer. Patient Compliance and Safety A significant benefit of blister packaging lies in patient compliance. The organized and segmented nature of blister packs allows patients to track their medication intake effectively. It can significantly aid elderly patients or those taking multiple medications at different times of the day. By reducing errors in medication consumption, blister packs enhance patient safety. Ease of Use and Portability Blister packs are designed for consumer convenience. They are lightweight, compact, and easily portable, making them ideal for on-the-go consumers. The simplicity in popping a pill out from its compartment enhances the product’s ease of use. The Business Perspective: Cost-Effectiveness and Marketing Opportunities From the business side, blister packs offer several benefits, including cost-effectiveness and marketing opportunities. Cost-Effectiveness Blister packaging can be highly cost-effective compared to other packaging solutions. The material used is typically less expensive, and the production process is often more streamlined. Also, because blister packs help maintain drug integrity, the rate of product returns or losses due to spoilage or damage is substantially reduced. Marketing Opportunities Lastly, blister packs offer unique marketing opportunities. The backing card provides ample space for branding, important drug information, instructions for use, and even promotional messages. This aspect can give pharmaceutical companies an edge in a highly competitive market. Environmental Considerations of Blister Packs Like any industry, pharmaceutical packaging must consider its environmental impact. While blister packs provide a multitude of benefits, they also have some downsides. These packs are often composed of a combination of plastic and aluminum, which are not biodegradable and difficult to recycle. As environmental awareness rises, pharmaceutical companies are challenged to find more sustainable solutions without compromising the product’s integrity and the consumer’s safety and convenience. The Future of Blister Packs in Pharmaceuticals With the advantages blister packs offer, they’re here to stay. However, the push for more sustainable practices is driving innovation in this sector. We can expect advancements in materials science to produce more environmentally-friendly blister packs in the future. Furthermore, technology may introduce smart blister packs, capable of reminding patients to take their medication, improving adherence rates even further. In summary, the pharmaceutical industry’s dependence on blister packs is multifaceted and rooted in both practical and business considerations. However, as the industry evolves, so too will its packaging methods, with an increasing focus on sustainability and technological innovation. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Blister Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts