Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

We build durable and efficient packaging for simple to the most complex products.

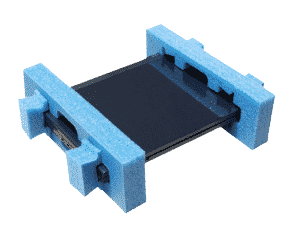

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

California has long been a pioneer in environmental protection, and its stringent packaging laws are a testament to its commitment to sustainability. Among these regulations, the Rigid Plastic Packaging Container (RPPC) Act stands out as a game-changer. This law not only promotes eco-friendly packaging but also holds manufacturers accountable for reducing packaging waste. In this blog, we will delve into the RPPC Act, exploring its key provisions, impact, and implications for businesses and consumers. Understanding the RPPC Act The RPPC Act, enacted in 1991, places specific requirements on manufacturers of rigid plastic packaging containers sold in California. Its primary objective is to minimize packaging waste and promote recycling. Here are the key provisions of the RPPC Act: Minimum Recycled Content: One of the fundamental requirements of the RPPC Act is that manufacturers must use a minimum percentage of recycled content in the production of rigid plastic packaging containers. This provision encourages the use of post-consumer recycled materials in packaging, reducing the demand for virgin plastics. Recycling Symbols: To enhance recycling efforts and raise consumer awareness, the RPPC Act mandates that qualifying containers bear specific recycling symbols. These symbols provide valuable information to consumers about the recyclability of the packaging. Compliance and Penalties: Non-compliant products, those that do not meet the RPPC Act’s requirements, may face penalties. Manufacturers are obligated to ensure that their packaging adheres to the law’s provisions to avoid potential fines and legal repercussions. Impact on Packaging Sustainability The RPPC Act has had a profound impact on packaging sustainability in California and serves as a model for other states and regions. Here’s how this law has contributed to a greener and more sustainable packaging landscape: Encouraging the Use of Recycled Materials: By mandating a minimum percentage of recycled content in rigid plastic packaging containers, the RPPC Act incentivizes manufacturers to incorporate recycled materials into their products. This reduces the demand for new plastic production and conserves resources. Promoting Recycling Education: The requirement for specific recycling symbols on packaging helps educate consumers about proper recycling practices. When consumers see these symbols, they are more likely to participate in recycling programs, diverting more packaging waste from landfills. Reducing Packaging Waste: Perhaps the most significant impact of the RPPC Act is its role in reducing packaging waste. By setting recycling standards and encouraging the use of recycled materials, the law minimizes the environmental footprint of packaging. Implications for Businesses and Consumers Compliance Challenges for Manufacturers: Manufacturers operating in California must invest in research, development, and production processes that align with the RPPC Act’s requirements. This may involve sourcing recycled materials, redesigning packaging, and ensuring proper labeling. Competitive Advantage: Businesses that proactively comply with the RPPC Act gain a competitive advantage in California’s environmentally conscious market. They can market their products as eco-friendly and responsible choices. Consumer Empowerment: Consumers benefit from the RPPC Act through increased awareness of recycling symbols and access to more sustainable packaging options. They can make informed choices that align with their environmental values. If you are interested in California packaging compliant solutions, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging labels and graphics serve as the face of a product, making them an integral part of brand identity and consumer appeal. However, the longevity of these visual elements can be compromised by factors such as UV radiation, moisture, temperature fluctuations, and physical handling. In this blog, we’ll explore effective strategies to safeguard packaging labels and graphics, ensuring they retain their vibrancy and impact throughout the product’s lifecycle. Understanding the Challenge Before we delve into preventive measures, it’s important to understand why packaging labels and graphics fade: UV Radiation: Exposure to ultraviolet (UV) radiation, whether from sunlight or artificial light sources, can break down the pigments and dyes in inks, causing colors to fade over time. Oxygen and Moisture: Oxidation and moisture exposure can lead to chemical reactions that alter the properties of inks and substrates, resulting in fading and degradation. Temperature Fluctuations: Rapid temperature fluctuations can cause materials to expand and contract, potentially leading to cracks, tears, and peeling of labels and graphics. Abrasion and Physical Handling: Rough handling during transportation and storage can cause labels and graphics to rub against surfaces or other packaging materials, leading to wear and tear. Effective Strategies for Prevention To ensure that packaging labels and graphics remain visually appealing and informative, consider implementing the following preventive measures: UV-Resistant Inks: Choose UV-resistant inks designed to withstand exposure to UV radiation. These inks are formulated to be less susceptible to fading and degradation. Protective Coatings: Apply protective coatings, such as UV-resistant varnishes or laminates, over labels and graphics. These coatings create a barrier that shields against UV radiation, moisture, and abrasion. Thoughtful Material Selection: Opt for packaging materials that offer inherent UV protection. UV-resistant films and substrates can serve as a barrier to minimize the impact of UV radiation on labels and graphics. Controlled Storage and Display: Educate retailers and consumers on the importance of storing products away from direct sunlight and fluorescent lighting to minimize UV exposure. Proper storage conditions can significantly extend the life of labels and graphics. Quality Inks and Printing Processes: Invest in high-quality printing processes and inks that are less prone to fading. Options may include pigment-based inks and digital printing technologies known for their durability. Regular Quality Control: Implement regular quality control checks to ensure that printing and labeling processes meet industry standards and are resistant to fading. Consistent quality assurance is essential. Temperature and Humidity Control: Maintain controlled environmental conditions in storage and display areas to prevent extreme temperature fluctuations and humidity levels that can damage labels and graphics. Gentle Handling: Train employees and handlers to practice gentle and careful product handling to avoid physical damage to labels and graphics during transportation and storage. Ensuring Long-Lasting Impact Preventing packaging labels and graphics from fading is not just a matter of aesthetics; it’s an investment in preserving brand identity, consumer trust, and the overall appeal of a product. By implementing these proactive strategies, businesses can ensure that their packaging remains vibrant and impactful, reinforcing brand recognition and delivering a positive consumer experience throughout the product’s journey from production to purchase. If you are interested in labels and custom packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Thermoform inserts are a versatile and essential component in various industrial and consumer applications. They are produced through a process called thermoforming, where a plastic sheet is heated to a pliable forming temperature, formed to a specific shape in a mold, and trimmed to create a usable product. In this blog, we’ll delve into the properties, applications, and other relevant aspects of thermoform inserts. Properties of Thermoform Inserts Material Flexibility: Thermoform inserts can be made from a wide range of plastics, including like PVC, PET and HIPS. Each material offers different characteristics like rigidity, clarity, and resistance to impact and chemicals. Durability: These inserts are known for their strength and durability. They can withstand significant impact and are resistant to many chemicals, making them suitable for protective purposes. Lightweight: Despite their strength, thermoform inserts are relatively lightweight, which is beneficial for reducing shipping and handling costs. Customizability: The thermoforming process allows for high levels of customization. Inserts can be formed into virtually any shape and size, accommodating a wide range of products. Aesthetic Appeal: Thermoform inserts can have smooth or textured surfaces, and can be transparent or colored. This makes them visually appealing and suitable for display purposes. Applications of Thermoform Inserts Packaging Solutions: One of the most common uses of thermoform inserts is in product packaging. They are used to securely hold products in place, often seen in the packaging of electronics, cosmetics, and pharmaceuticals. Medical Industry: In the medical field, thermoform inserts are used for packaging sterile medical devices and equipment due to their ability to be sterilized and their contaminant-free nature. Automotive Industry: They are also used in the automotive industry for creating durable and lightweight parts, such as dashboards, door panels, and interior consoles. Food Industry: Thermoform inserts are used for food packaging, given their ability to be sealed for freshness and their compliance with food safety standards. Retail Display: Retail industries use these inserts for aesthetically pleasing product displays that protect the product while showcasing it effectively. Advantages and Considerations Cost-Effective: Thermoforming is a cost-effective production process, especially for medium to large runs, making thermoform inserts a budget-friendly option. Environmental Considerations: Many thermoform plastics are recyclable, which is a crucial consideration in today’s environmentally conscious market. However, the choice of material and recycling programs available can affect this aspect. Design and Prototyping: The flexibility in design makes thermoform inserts ideal for custom applications. Rapid prototyping is often possible, allowing for quick turnaround from design to production. Limitations: While versatile, there are limitations in terms of the depth and complexity of shapes that can be achieved compared to other forming processes like injection molding. Conclusion Thermoform inserts play a crucial role in various industries due to their unique properties like durability, lightweight nature, and customizability. Their applications range from packaging to automotive parts, showcasing their versatility. When considering thermoform inserts for a project, it’s essential to weigh factors like material properties, environmental impact, and design requirements to ensure they meet the specific needs of the application. With ongoing advancements in materials and thermoforming technology, the potential uses and benefits of thermoform inserts continue to expand. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Thermoform Insert Facebook Twitter LinkedIn Pinterest Relevant Posts

Straight Tuck End (STE) folding cartons are a popular and widely used type of packaging for consumer goods such as food, beverage, cosmetics, and household items. In this blog, we will explore the various aspects of STE folding cartons, including the materials used, customization options, sustainability considerations, and their benefits compared to other packaging styles. Materials Used in Straight Tuck End Folding Cartons One of the most common materials used for STE folding cartons is paperboard. Paperboard is a thick and stiff sheet made from recycled paper that is economical and easily printable. It is also recyclable or biodegradable, making it an environmentally friendly choice. The most popular material is SBS (Solid Bleached Sulfate) paperboard. SBS is a high-quality, bright white paperboard that provides a premium look and feel. It is often used for luxury or high-end products where a premium appearance is important. Chipboard is another material that can be used for STE folding cartons. Chipboard is a low-cost that provides good product protection. It is a less dense and less durable material than other alternatives, but it is still a popular choice for certain applications. CNK (Clay Coated Newsback) and CCNB (Clay Coated Natural Back) paperboard are another option that is commonly used for STE folding cartons. CNK and CCNB is a durable and printable paperboard materials that provide good product protection and are a cost-effective alternative to SBS paperboard. Customization Options Straight Tuck End folding cartons can be easily customized to meet your specific needs and help you stand out in a crowded market. They can be printed with your company’s branding and product information, and they can be manufactured in a variety of sizes and shapes to fit your product. You can also choose from a range of finishes, such as matte or glossy, to give your cartons a unique look and feel. Sustainability Considerations Sustainability is an important consideration for many companies when it comes to packaging. Straight Tuck End folding cartons made from paperboard are a sustainable option as paperboard can be recycled or biodegraded after use. However, it’s important to consider the entire lifecycle of the product, including production and transportation, to ensure that your packaging is as sustainable as possible. Packaging Applications STE folding cartons are a versatile packaging option that can be used for a wide range of products and industries. They are suitable for both manual and automated packing processes and can be used for food, beverage, cosmetic, and household items. They are also commonly used for gift and premium packaging as well as for over-the-counter products. Benefits and Advantages of Straight Tuck End Folding Cartons There are several benefits and advantages to using Straight Tuck End folding cartons compared to other packaging styles. Some of these include: Cost-effective: STE folding cartons are an economical option that provides good product protection. Customizable: They can be easily customized to meet your specific needs and can be printed with your company’s branding and product information. Versatile: They are suitable for a wide range of products and industries and can be used for both manual and automated packing processes. Sustainable: Paperboard is recyclable or biodegradable, making STE folding cartons a sustainable option for those looking to minimize their environmental impact. Summary: Straight Tuck End Folding Cartons In conclusion, Straight Tuck End folding cartons are a popular and versatile option for packaging consumer goods. With a range of material options, including CNK and CCNB, SBS, chipboard, and CNK, and the ability to be easily customized, STE folding cartons offer a cost-effective and sustainable solution for a wide range of products and industries. Whether you are looking to package food, beverages, cosmetics, or household items, STE folding cartons provide good product protection and a premium look and feel that can help you stand out in a crowded market. With their numerous benefits and advantages, STE folding cartons are a smart choice for your packaging needs. If you are interested in folding cartons, then contact Brown Packaging today for assistance. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Straight Tucke End Folding Carton Facebook Twitter LinkedIn Pinterest Relevant Posts

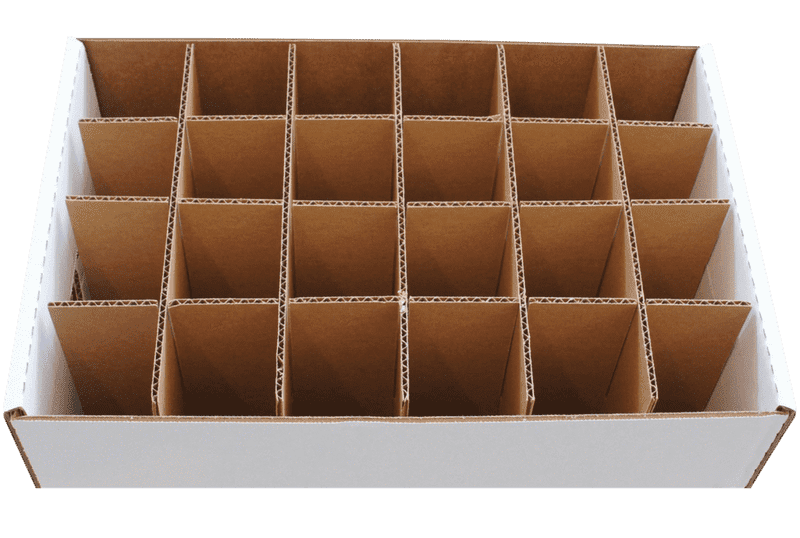

Corrugated partition inserts are an innovative packaging solution that can significantly enhance the functionality and efficiency of boxes. These inserts are made from corrugated cardboard, a versatile and durable material widely used in the packaging industry. By incorporating partition inserts, boxes can be transformed into organized compartments, providing protection, support, and separation for the packaged items. In this blog, we will explore the various benefits and applications of corrugated partition inserts, as well as their contribution to sustainable packaging solutions. Benefits of Corrugated Partition Inserts Protection and Stability Corrugated partition inserts offer excellent protection for delicate or fragile items during transit. The inserts can be designed to fit snugly inside the box, creating individual compartments that prevent the packaged items from shifting or colliding with each other. This added stability minimizes the risk of damage and ensures that products arrive at their destination in optimal condition. Improved Organization and Presentation With corrugated partition inserts, boxes can be organized and segmented into multiple compartments, allowing for better item separation and organization. This is particularly beneficial for industries such as cosmetics, electronics, and food, where products need to be individually stored or displayed. The inserts also contribute to a visually appealing presentation, creating an attractive and professional appearance for the packaged items. Enhanced Efficiency in Handling and Storage Partition inserts streamline the handling and storage process by simplifying the identification and retrieval of specific items. By providing separate compartments for each product, inserts eliminate the need for time-consuming searching or sorting through a box full of items. This increased efficiency can greatly benefit distribution centers, warehouses, and retail operations. Customizability and Versatility Corrugated partition inserts can be customized to fit the specific dimensions and requirements of various products. Manufacturers can design inserts with different cell sizes and configurations, allowing for optimal placement and protection of items with different shapes, sizes, and fragility levels. This versatility makes partition inserts suitable for a wide range of industries and product types. Applications of Corrugated Partition Inserts Electronics and Technology: The electronics industry often deals with delicate components that require individual protection. Corrugated partition inserts can safeguard circuit boards, computer chips, and other electronic parts from damage during shipping. The inserts ensure that each component remains secure and isolated, reducing the risk of static discharge and other potential hazards. Pharmaceutical and Healthcare: In the pharmaceutical and healthcare sectors, the integrity and safety of products are paramount. Partition inserts can be utilized to separate and protect vials, syringes, medicine bottles, and other medical supplies. These inserts help prevent contamination, breakage, and the mixing of different substances, ensuring the quality and efficacy of pharmaceutical products. Food and Beverage: Corrugated partition inserts find applications in the food and beverage industry, particularly for the packaging of fragile or delicate food items. Inserts can keep items like glass bottles, jars, or delicate products secure and separate from one another, minimizing the chance of breakage or spoilage. Additionally, partitioned compartments can be used to package multiple items together, allowing for easy assembly of gift sets or sampler packs. Sustainability and Corrugated Partition Inserts Corrugated partition inserts contribute to sustainable packaging solutions in several ways: Recyclability Like corrugated cardboard boxes, partition inserts are recyclable and can be transformed into new paper products. By using recyclable materials, companies can reduce their environmental impact and support a circular economy. Reduced Material Consumption Partition inserts optimize the use of materials by providing individual compartments, eliminating the need for excessive cushioning or additional packaging. This reduces the overall material consumption and waste generation. Lightweight and Space-Efficient Corrugated cardboard partition inserts are lightweight, which helps reduce transportation costs and carbon emissions. Their space-efficient design allows for more products to be packed in a single shipment, maximizing the use of cargo space and minimizing the need for additional vehicles. Biodegradability Corrugated partition inserts are made from natural fibers, which means they are biodegradable. When disposed of properly, they break down naturally over time without releasing harmful pollutants into the environment. Renewable Material Source Corrugated cardboard is made from a renewable resource—trees. Responsible forestry practices ensure the sustainability of the raw materials used in the production of corrugated partition inserts, minimizing the impact on forests and promoting environmental stewardship. Summary: Corrugated Partition Inserts Corrugated partition inserts offer numerous benefits for packaging applications, ranging from enhanced protection and organization to improved efficiency and presentation. Their customizability and versatility make them suitable for a wide range of industries, including electronics, pharmaceuticals, and food and beverage. Moreover, these inserts contribute to sustainable packaging solutions by being recyclable, lightweight, space-efficient, biodegradable, and sourced from renewable materials. By incorporating corrugated partition inserts into their packaging designs, companies can enhance the functionality of their boxes while minimizing their environmental footprint. If you are interested in corrugated partitions or other types of inserts, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts