Home » Guide to Corrugated Gaylord Boxes: Sizes and Applications

Guide to Corrugated Gaylord Boxes: Sizes and Applications

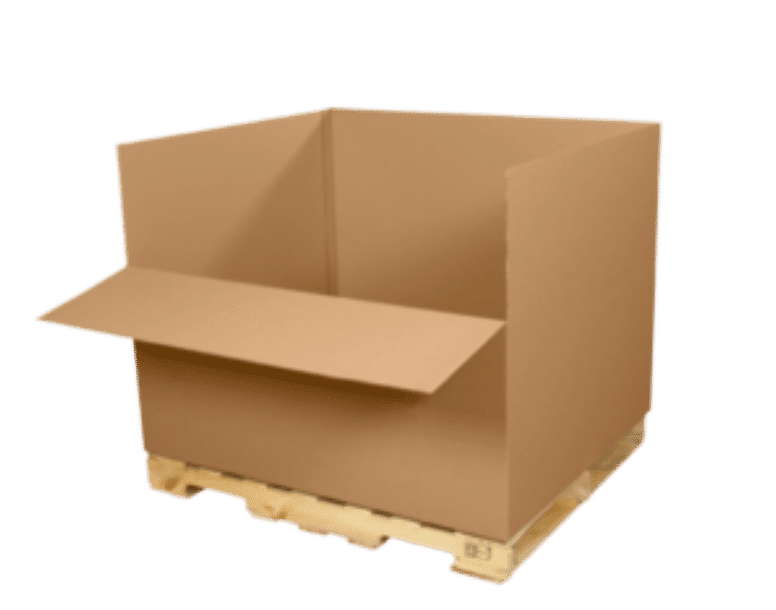

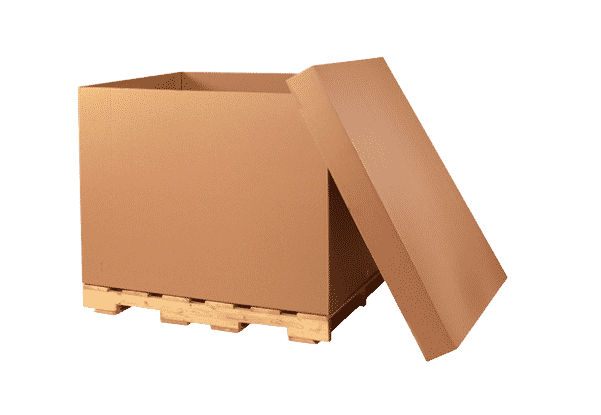

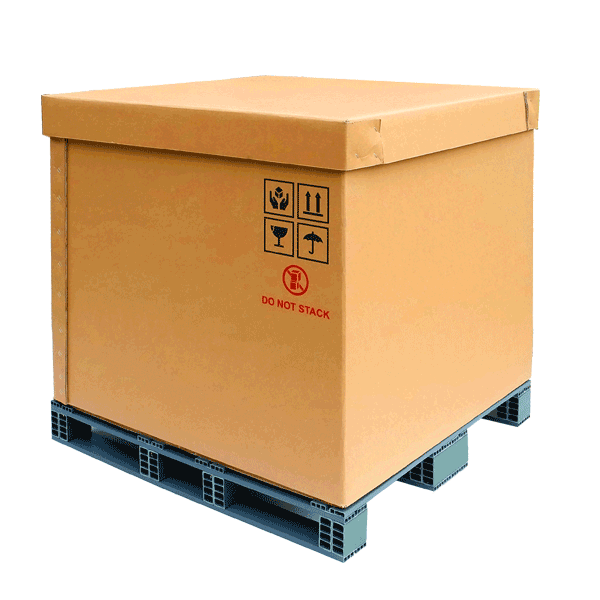

For industries seeking efficient solutions for material storage and transportation, corrugated gaylord boxes have emerged as a viable alternative to plastic totes and super sacks. These lightweight and cost-effective containers are not only environmentally friendly but also surprisingly versatile. Despite misconceptions about their single-use nature, gaylord boxes boast impressive durability and reusability, making them a favorite among businesses. In this guide, we’ll explore the diverse landscape of gaylord box sizes, shedding light on the various options available to manufacturers, retailers, and distributors alike.

Versatility of Corrugated Gaylord Boxes

Before we delve into the specifics of sizing, let’s revisit what makes Corrugated gaylord boxes a staple in the logistics world. Designed to accommodate bulk materials, these containers typically feature cubic or rectangular, ensuring easy access and secure storage.

Corrugated Gaylord Box Sizes: An Overview

Corrugated gaylord boxes span a range of sizes to suit diverse needs across industries. Sizing is typically expressed in inches, measuring length, width, and height. Below, we’ll detail some of the most common gaylord box sizes, along with their dimensions:

Standard Corrugated Gaylord Size: 48 x 40 x 36″

The quintessential gaylord box, measuring 48 inches in length, 40 inches in width, and 36 inches in height. Often rectangular or octangular in shape with three to five walls, these boxes are the most prevalent, with up to 500-550 boxes fitting on a single trailer when properly palletized. The four and five wall variants of this size boast weight capacities ranging from 4,000 to 5,000 lbs. A standout feature is their compatibility with standard pallet dimensions, allowing for double stacking within trailers. This makes them ideal for metal, plastic, and electronic waste recycling. Moreover, these boxes can be bound to pallets, enabling multiple reuses and contributing to their resale value.

Pallet Container: 40 x 40 x 40″

Similar in weight and carrying capacity to the standard 48 x 40 x 36″ corrugated gaylord box, this size measures 40 inches in each dimension. They offer versatility for internal logistics and transportation. The remarkable advantage is their ability to fit and stack on both 40 x 40 and 48 x 40 pallets. This flexibility, coupled with the capacity to hold 3,000 lbs in the four and five wall variants, positions them as a preferred choice for many users.

Pallet Boxes: 40 x 30 x 30″

Measuring 40 inches in length, 30 inches in width, and 30 inches in height, these boxes vary in walls (2-5) and shapes (rectangular or octagonal). While their weight capacity depends on these factors, they are designed for lighter loads compared to the standard 48 x 40 x 36″ corrugated gaylord box. The typical 40 x 30 x 30″ box features 4 walls and holds around 1,200-1,500 lbs. Their advantage lies in their compatibility with standard 40 x 48 pallets, ensuring even stacking and easy transportation.

Small Corrugated Gaylords: 36 x 36 x 36″

Catering to more compact needs, these boxes measure 36 inches in each dimension and typically feature three or four walls. Their smaller stature and lower wall count result in reduced weight and carrying capacities compared to the standard 48 x 40 x 36″ corrugated gaylord box. Weight capacities usually range from 1,000 to 1,200 lbs. While they may hold less weight, these boxes offer two distinct advantages: a higher quantity can fit onto a trailer, and they often come with a lower price per unit.

Choosing the Perfect Fit: Factors to Consider

Selecting the right corrugated gaylord box size involves a careful evaluation of several factors:

- Materials Volume: Assess the quantity of materials you intend to store or transport.

- Storage Space: Consider the available storage area or warehouse dimensions.

- Weight Capacity: Ensure the chosen size can safely accommodate the weight of your materials.

- Transportation: Account for any transportation constraints, such as truck dimensions or shipping regulations.

Applications: Tailoring Sizes to Industries

Different industries benefit from various corrugated gaylord box sizes:

- Agriculture and Manufacturing: Optimal sizes vary for packing produce or components. Uses mid to large sizes.

- Retail and Distribution: Choose sizes that streamline packaging and distribution processes. Uses small to mid sizes.

- Recycling Centers: corrugated gaylord boxes facilitate sorting recyclables of varying volumes. Use mid to large sizes.

If you are interested in custom or stock corrugated gaylord boxes, then partner with Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Home » Guide to Corrugated Gaylord Boxes: Sizes and Applications

Why Custom Corrugated Boxes Remain a 2026 Essential Custom corrugated boxes continue to be the most relied-on packaging solution for industries ranging from industrial manufacturing

Corrugated boxes are a staple in the packaging world, known for their strength and versatility. However, maximizing their durability is key to ensuring products reach

RSC boxes are known for their efficiency and versatility, but their performance ultimately comes down to strength. Buyers often see numbers like ECT, BCT, and