Home » Foil Stamping In Packaging: A Buyer’s Guide

Foil Stamping In Packaging: A Buyer’s Guide

In the world of packaging, making a memorable impression is crucial. Packaging not only protects and delivers products but also serves as a powerful branding and marketing tool. Foil stamping, a decorative technique, has gained popularity as a means to add elegance, sophistication, and visual appeal to packaging. In this detailed blog, we will explore what foil stamping is in packaging and how it can elevate your brand’s image and make a lasting impact on customers.

What is Foil Stamping?

Foil stamping, also known as foil printing, mainly used in hot stamping, is a specialized printing process used to apply metallic or pigmented foil onto various materials, including paper, cardboard, plastics, and more. This process involves the application of heat and pressure to transfer the foil material onto the packaging surface. The result is a brilliant and eye-catching design that stands out from traditional printing methods.

How Foil Stamping Works

The foil stamping process consists of several key steps:

- Design Preparation: The first step involves creating a custom design or selecting pre-made foil stamping patterns or templates. This design will be transferred onto the packaging material.

- Die Creation: A metal die is fabricated based on the chosen design. The die is heated during the stamping process and serves as a mold for transferring the foil.

- Foil Feeding: The foil roll is placed above the packaging material, and a heat-activated adhesive is applied to the area where the foil will adhere.

- Stamping Process: The heated metal die is pressed onto the packaging material, transferring the foil onto the adhesive-coated area. The pressure and heat cause the foil to bond with the packaging surface, leaving the desired design in a brilliant metallic or pigmented finish.

- Cooling and Removal: After the foil is applied, it is allowed to cool, which sets it firmly onto the packaging material. Once cooled, any excess foil is removed, leaving only the stamped design.

Benefits of Foil Stamping in Packaging

Foil stamping offers a multitude of benefits that make it an attractive choice for packaging enhancement:

- Visual Appeal: Foil stamping adds a luxurious and eye-catching element to packaging, making it stand out on the shelf or in the hands of customers.

- Elegance and Sophistication: The reflective and shimmering qualities of foil create an impression of elegance, making it suitable for high-end and luxury products.

- Customization: Foil stamping allows for customization with various foil colors, including metallic, matte, and holographic options, enabling brands to tailor the design to their unique identity.

- Durability: Foil-stamped designs are resilient and resistant to fading, ensuring that the packaging maintains its visual appeal over time.

- Branding and Brand Recognition: Foil-stamped logos and branding elements increase brand recognition and help customers associate the packaging with the brand.

- Versatility: Foil stamping can be used on a wide range of packaging materials, such as boxes, labels, bags, and more, making it a versatile choice.

Applications of Foil Stamping in Packaging

Foil stamping can be applied to various packaging types and industries:

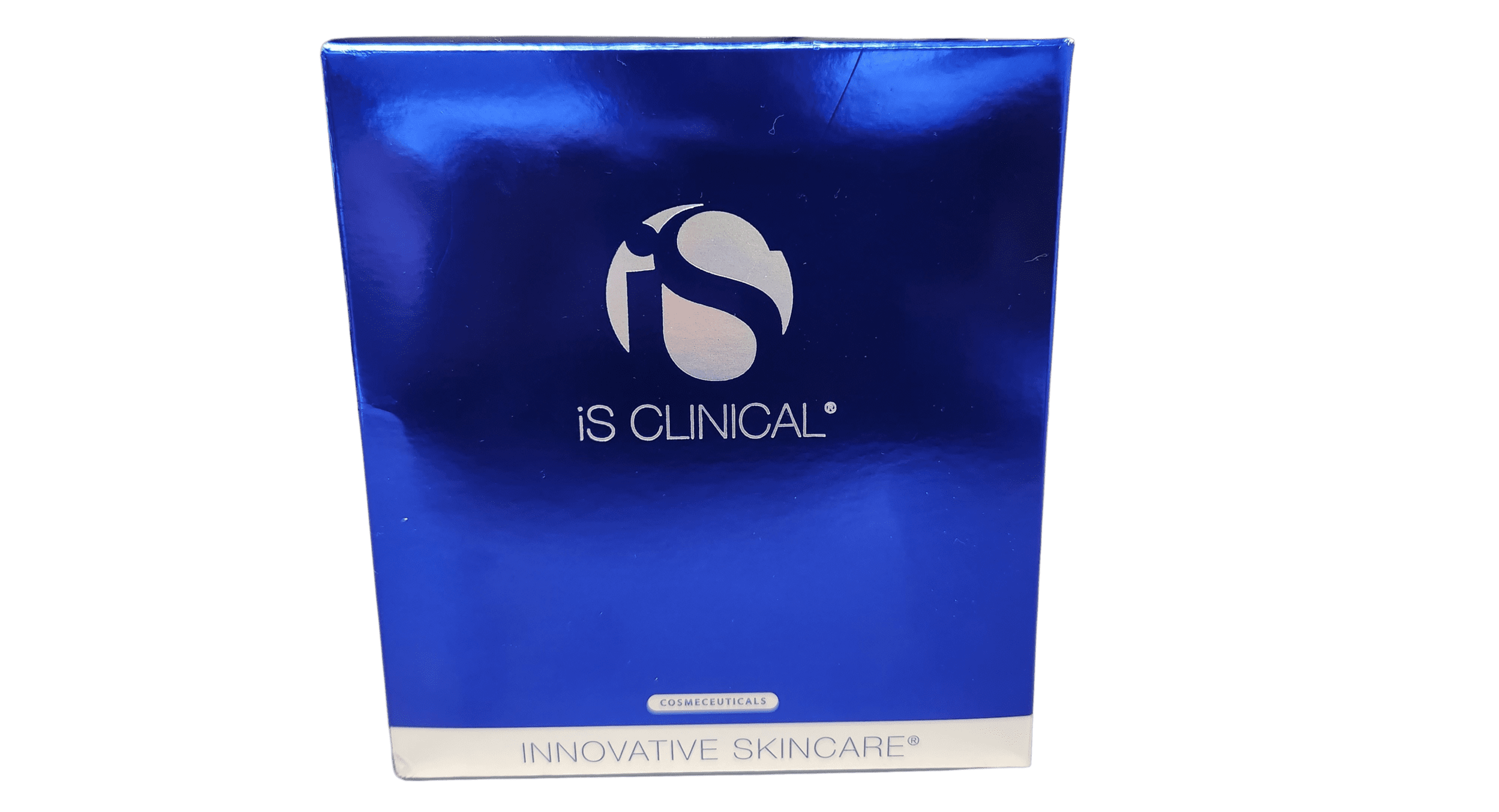

- Cosmetics: Foil stamping is commonly used for high-end cosmetic packaging to convey luxury and quality.

- Food and Beverages: Premium food and beverage products often feature foil-stamped labels or packaging to communicate exclusivity.

- Pharmaceuticals: Foil stamping on pharmaceutical packaging can enhance product visibility and compliance.

- Retail Packaging: Foil-stamped logos and branding elements on retail packaging create an upscale and memorable shopping experience.

- Event and Wedding Invitations: Foil-stamped invitations and stationery add a touch of elegance and sophistication to special occasions.

Conclusion

Foil stamping is a remarkable decorative technique that can transform ordinary packaging into extraordinary masterpieces. With its ability to add visual appeal, elegance, and brand recognition, foil stamping is a valuable tool for businesses aiming to make a lasting impression on customers and stand out in a competitive market. Whether used for branding, customization, or enhancing the perceived value of products, foil stamping is a versatile and impactful choice in the world of packaging.

If you are interested in packaging with foil stamping, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Foil Stamping In Packaging: A Buyer’s Guide

Choosing the right printing method for your packaging is very important. It is necessary to consider artwork, design, quantity, time frame and many more when

Before committing to a full production run, businesses often receive packaging samples to evaluate fit, functionality, print quality, and overall design. Whether it’s a digital

The packaging industry has undergone significant changes in recent years, with new technologies such as digital print revolutionizing the way packaging materials are produced. Digital