Sustainable Packaging

Explore our sustainable packaging products, including corrugated boxes, folding cartons, pouches, and stock packaging options. We offer eco-friendly materials and a variety of print and ink choices to fit your packaging needs. Choose from solutions designed to support sustainability and meet your business requirements.

Sustainable packaging refers to the use of materials and design methods that minimize environmental impact. This can include using recyclable or biodegradable materials, reducing excess packaging, and opting for renewable resources like paper, kraft, or corrugated materials. The goal is to reduce waste, conserve energy, and lessen the overall carbon footprint of packaging.

By choosing sustainable packaging, businesses help limit the negative effects of packaging waste on the environment. These products are often recyclable, compostable, or reusable, making them a more eco-friendly option. Sustainable packaging balances the need for protection and branding with the responsibility to preserve resources for future generations.

Our sustainable packaging products include custom corrugated boxes, folding cartons, pouches, and a variety of stock options. Each product is designed with eco-friendly materials to help reduce environmental impact while meeting your packaging needs.

Corrugated Boxes

- Regular slotted Container (RSC)

- Half Slotted Container (HSC)

- Full Overlap (FOL)

- Roll End Tuck Top (RETT/Mailer)

- Additional Box Styles

- Corrugated Inserts

Folding Cartons

- Straight Tuck End (STE)

- Reverse Tuck End (RTE)

- Full Seal

- Auto Bottom

- Chipboard Inserts

Pouches

- Stand Up

- Lay Flat

- Gusseted

- Retort

- Block Bottom

- Sachets

- Additional Pouch Styles

Stock Packaging Products

- Corrugated Packaging

- Shipping Boxes

- Chipboard Packaging

- Edge Protectors

- Mailers (Kraft)

- Kraft Tape

- Kraft Paper

At Brown Packaging, we prioritize eco-friendly packaging solutions that help reduce environmental impact. Our commitment to green packaging ensures that we provide sustainable materials, allowing you to make responsible choices for your business and the planet.

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

We provide packaging solutions designed to help reduce your carbon footprint through eco-friendly production, efficient shipping, and sustainable materials. From pallet optimization to energy-efficient manufacturing, our approach ensures that your packaging minimizes environmental impact at every stage.

Our custom structural design services allow us to minimize material use without compromising protection. By optimizing the design for strength and efficiency, we help you reduce excess packaging and the environmental costs associated with waste. Smarter packaging design means a lower carbon footprint overall.

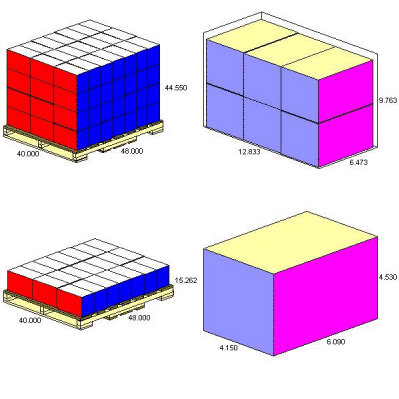

With CAPE software, we optimize pallet configurations to maximize space and load efficiency. This results in fewer trips and lower fuel usage during transportation, reducing your carbon footprint. By making the most of every pallet, we help you achieve more eco-friendly logistics.

We offer digital samples, eliminating the need for multiple physical prototypes, which reduces waste and energy use in production. By creating virtual models, we help you save resources while speeding up the design process. This eco-friendly approach helps minimize the carbon footprint of packaging development.

We focus on eco-friendly production processes that minimize waste and reduce energy consumption. By using sustainable materials and optimizing manufacturing efficiency, we help lower the carbon footprint of your packaging. This commitment to sustainable production ensures a smaller environmental impact from the start.

Our lightweight and efficient packaging solutions help reduce transportation emissions by maximizing space and minimizing weight. By designing packaging that is easy to transport, we help your business cut down on fuel consumption and overall shipping costs, contributing to a reduced carbon footprint.

We design packaging with durability and reusability in mind, extending the useful life of each product. By creating packaging that can be used multiple times before disposal or recycling, we help reduce waste and conserve resources, contributing to a smaller environmental footprint.

We prioritize sourcing materials from local suppliers to reduce transportation distances and emissions. By keeping production and distribution close to home, we help cut down on the environmental impact associated with long-distance shipping. Local sourcing ensures a more sustainable and efficient supply chain.

We offer packaging made from eco-friendly, recyclable, and biodegradable materials that reduce reliance on virgin resources. By using sustainable materials, we help decrease the carbon emissions associated with material extraction and production. This ensures that your packaging has a smaller environmental impact from the very start.

Interested In Sustainable Packaging Solutions?

Discover the latest insights on sustainable packaging by exploring our blog, where we share tips and innovations to help businesses reduce their environmental impact. Stay informed about eco-friendly packaging solutions and learn how your company can make a difference through sustainability.

High Impact Polystyrene, commonly known as HIPS, is a versatile and widely used thermoplastic renowned for its unique blend of properties. This material is crucial in various industries, including consumer goods and packaging, due to its high-impact strength, rigidity, affordability, and ease of processing. Essential Properties of HIPS HIPS boasts several properties that make it an excellent choice for numerous applications: High Impact Strength: Provides durability and resistance to physical impacts. Rigidity: Maintains shape and structural integrity under stress. Chemical Resistance: Withstands exposure to many chemicals, oils, and greases. Biological Resistance: Resists degradation from biological factors like fungi and bacteria. Water Resistance: Impermeable qualities make it suitable for applications requiring moisture resistance. Fatigue Resistance: Capable of enduring repeated stress without losing its form, ideal for components like living hinges. Thermal Insulation: Offers significant insulation properties, beneficial in both industrial and consumer products. Electrical Insulation: Highly resistant to electricity, making it safe for use in electronic components. Affordability and Recyclability: Cost-effective and fully recyclable, supporting environmental sustainability. Diverse Applications of HIPS HIPS’s versatility allows its use across various sectors: Consumer Goods: Utilized in products requiring durability and impact resistance, such as toys, household appliances, and office supplies. Packaging Materials: Ideal for making clamshell containers, blister packs, and trays due to its moldability and cost-effectiveness. Automotive Industry: Used in components like interior trim parts, instrument panels, and exterior body parts due to its lightweight and sturdy nature. Construction Industry: Forms part of materials such as wall panels, ceiling tiles, and insulation boards, thanks to its insulation properties. Medical Industry: Common in the production of medical devices and packaging, valued for its chemical resistance and stability. Manufacturing Process of HIPS The production of HIPS involves several steps: Polymerization: Styrene monomers are polymerized using catalysts like benzoyl peroxide to form the HIPS polymer. Mixing: The polymer is blended with impact modifiers, stabilizers, and pigments to enhance its properties and appearance. Molding: HIPS can be shaped through extrusion or injection molding, allowing it to be formed into various products. Cooling and Finishing: Post-molding, HIPS is cooled and can undergo additional processing like trimming and polishing to achieve the desired quality. Environmental Considerations While HIPS is not biodegradable, it is recyclable. Recycling HIPS contributes to waste reduction and resource conservation, mitigating the environmental impact associated with plastic production. Frequently Asked Questions About HIPS Is HIPS food safe? Yes, when certified, HIPS is safe for food contact applications. Difference between HIPS and ABS? ABS is generally more robust with better temperature resistance, but HIPS is more cost-effective. Can HIPS be painted or printed on? Yes, HIPS can be easily painted or printed on, provided the surface is properly prepared. Color options for HIPS? Available in a broad spectrum of colors, including custom shades to meet specific project requirements. Conclusion High Impact Polystyrene (HIPS) stands out as a valuable material in the realm of plastics due to its excellent properties and wide range of applications. From packaging and automotive parts to household items and medical devices, HIPS continues to be a preferred choice for manufacturers seeking a reliable, cost-effective, and versatile material. As the industry advances, the sustainability and recyclability of HIPS make it even more significant in our ongoing journey towards environmental consciousness. For further details or inquiries about using HIPS for your packaging and manufacturing needs, please contact Brown Packaging. We are committed to delivering high-quality, sustainable packaging solutions tailored to your specifications. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Thermoform Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In the world of packaging, the visual appeal of your product plays a significant role in catching the customer’s eye and leaving a lasting impression. Roll End Tuck Top (RETT) boxes, known for their durability and versatility, provide an excellent canvas to enhance the presentation of your products. In this detailed blog, we will explore 12 effective strategies and tips on how to maximize the presentation of your RETT boxes to create a memorable unboxing experience for your customers. Creative Branding Custom Printing Consistency Across Products Window Inserts Custom Die-Cut Shapes Matte or Glossy Finish Branding Inside the Box Personalized Touch Seasonal or Limited-Edition Packaging Professional Photography Creative Branding Utilize the ample space on RETT boxes for creative branding. Include your company logo, eye-catching graphics, and product information. A well-designed box instantly communicates your brand identity and sets the tone for the unboxing experience. Custom Printing Invest in high-quality custom printing to ensure that your RETT boxes are visually striking. Vibrant colors and sharp imagery can make your packaging stand out and pique the customer’s interest. Consistency Across Products Maintain consistency in your packaging design across different products or product lines. A cohesive look reinforces your brand and makes your products easily recognizable. Window Inserts Consider adding window inserts to your RETT boxes. These transparent openings allow customers to preview the product inside, adding intrigue and enticing them to open the box. Custom Die-Cut Shapes Opt for custom die-cut shapes for your RETT boxes to make them unique and attention-grabbing. Unconventional shapes can make your packaging more memorable. Matte or Glossy Finish Choose between matte and glossy finishes to complement your brand’s aesthetics. Matte finishes exude sophistication, while glossy finishes provide a polished and vibrant look. Branding Inside the Box Don’t neglect the interior of your RETT boxes. Adding branding elements, messages, or design accents inside the box enhances the overall unboxing experience and surprises customers. Personalized Touch Consider adding a personalized touch, such as a handwritten thank-you note or a small promotional item, to show appreciation to your customers and leave a positive impression. Seasonal or Limited-Edition Packaging For special occasions or limited-edition products, create seasonal or unique packaging designs. These limited runs can generate excitement and encourage purchases. Professional Photography When showcasing your products online or in marketing materials, use professional photography to highlight the packaging’s visual appeal and its role in enhancing the product presentation. Conclusion Maximizing the presentation of your RETT boxes involves careful consideration of design, materials, and branding. These packaging strategies can significantly impact the customer’s perception of your products and brand. By investing in creative design, custom printing, and unique features, you can create a memorable unboxing experience that leaves a lasting impression on your customers, ultimately contributing to increased brand loyalty and customer satisfaction. If you are interested in roll end tuck top boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Roll End Tuck Top (RETT) Facebook Twitter LinkedIn Pinterest Relevant Posts

Creating an effective Point of Purchase (POP) display can be a game changer for any retail business, influencing buying decisions and enhancing product visibility. For packaging buyers, understanding the journey from concept to completion of a POP display is crucial. This blog will walk you through each step of the process, ensuring that you have the knowledge and tools to create a successful display. Step 1: Understanding the Objective Define Your Goals: Before you begin designing a POP display, it’s important to define what you hope to achieve. Are you looking to increase brand awareness, promote a new product, or boost sales of an existing product? Your goals will shape every decision you make going forward. Step 2: Research and Planning Market Research: Conduct research to understand your target audience’s preferences and behaviors. Look at competitors’ displays to identify what works and what doesn’t. Budget Planning: Determine your budget for the POP display. This will help guide your choices regarding materials, size, and design complexity. Step 3: Design and Prototyping Creative Design: Work with designers to develop the concept. This stage should embody creativity that aligns with your brand and meets the defined objectives. Use engaging graphics, eye-catching colors, and effective messaging that resonates with your target audience. Prototyping: Build a prototype of your POP display. This is a critical step to visualize how the display will look in a real environment and make necessary adjustments before mass production. Step 4: Choosing Materials Material Selection: Choose materials that not only fit within your budget but also reflect the quality of your brand. Consider durability, especially if the display will be used in high-traffic areas. Options range from cardboard and plastics to metal and wood, depending on the display’s required longevity and aesthetic. Step 5: Production Manufacturing: Once the design and materials are finalized, the production phase begins. Ensure quality control standards are in place to avoid any issues that could detract from the display’s effectiveness. Step 6: Logistics Distribution: Plan the logistics of getting your POP displays to their locations. Consider factors like assembly, transportation, and installation. Ensuring that displays arrive on time and in perfect condition is critical. Step 7: Installation Setting Up: Install your POP displays at the chosen locations. Proper installation is crucial to ensure that the displays are secure and function as intended. Step 8: Monitoring and Evaluation Performance Tracking: Monitor the performance of the displays regarding customer engagement and sales impact. This can involve direct sales metrics, customer feedback, and observational studies. Feedback and Adjustments: Use the data collected to understand what aspects of the display are working and what might need tweaking. Continuous improvement will help maximize the effectiveness of future displays. Conclusion The journey from concept to completion for a POP display involves careful planning, creativity, and strategic execution. By understanding each step of the process, packaging buyers can ensure that their POP displays effectively meet their goals, attract customers, and drive sales. Whether it’s a simple cardboard stand or a complex digital interactive display, the right approach to creating a POP display can make a significant difference in any retail environment. If you are interested in POP displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts