Sustainable Packaging

Explore our sustainable packaging products, including corrugated boxes, folding cartons, pouches, and stock packaging options. We offer eco-friendly materials and a variety of print and ink choices to fit your packaging needs. Choose from solutions designed to support sustainability and meet your business requirements.

Sustainable packaging refers to the use of materials and design methods that minimize environmental impact. This can include using recyclable or biodegradable materials, reducing excess packaging, and opting for renewable resources like paper, kraft, or corrugated materials. The goal is to reduce waste, conserve energy, and lessen the overall carbon footprint of packaging.

By choosing sustainable packaging, businesses help limit the negative effects of packaging waste on the environment. These products are often recyclable, compostable, or reusable, making them a more eco-friendly option. Sustainable packaging balances the need for protection and branding with the responsibility to preserve resources for future generations.

Our sustainable packaging products include custom corrugated boxes, folding cartons, pouches, and a variety of stock options. Each product is designed with eco-friendly materials to help reduce environmental impact while meeting your packaging needs.

Corrugated Boxes

- Regular slotted Container (RSC)

- Half Slotted Container (HSC)

- Full Overlap (FOL)

- Roll End Tuck Top (RETT/Mailer)

- Additional Box Styles

- Corrugated Inserts

Folding Cartons

- Straight Tuck End (STE)

- Reverse Tuck End (RTE)

- Full Seal

- Auto Bottom

- Chipboard Inserts

Pouches

- Stand Up

- Lay Flat

- Gusseted

- Retort

- Block Bottom

- Sachets

- Additional Pouch Styles

Stock Packaging Products

- Corrugated Packaging

- Shipping Boxes

- Chipboard Packaging

- Edge Protectors

- Mailers (Kraft)

- Kraft Tape

- Kraft Paper

At Brown Packaging, we prioritize eco-friendly packaging solutions that help reduce environmental impact. Our commitment to green packaging ensures that we provide sustainable materials, allowing you to make responsible choices for your business and the planet.

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

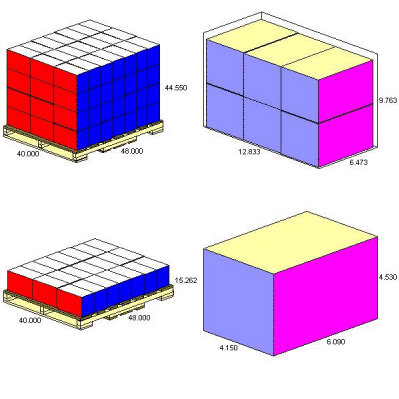

We provide packaging solutions designed to help reduce your carbon footprint through eco-friendly production, efficient shipping, and sustainable materials. From pallet optimization to energy-efficient manufacturing, our approach ensures that your packaging minimizes environmental impact at every stage.

Our custom structural design services allow us to minimize material use without compromising protection. By optimizing the design for strength and efficiency, we help you reduce excess packaging and the environmental costs associated with waste. Smarter packaging design means a lower carbon footprint overall.

With CAPE software, we optimize pallet configurations to maximize space and load efficiency. This results in fewer trips and lower fuel usage during transportation, reducing your carbon footprint. By making the most of every pallet, we help you achieve more eco-friendly logistics.

We offer digital samples, eliminating the need for multiple physical prototypes, which reduces waste and energy use in production. By creating virtual models, we help you save resources while speeding up the design process. This eco-friendly approach helps minimize the carbon footprint of packaging development.

We focus on eco-friendly production processes that minimize waste and reduce energy consumption. By using sustainable materials and optimizing manufacturing efficiency, we help lower the carbon footprint of your packaging. This commitment to sustainable production ensures a smaller environmental impact from the start.

Our lightweight and efficient packaging solutions help reduce transportation emissions by maximizing space and minimizing weight. By designing packaging that is easy to transport, we help your business cut down on fuel consumption and overall shipping costs, contributing to a reduced carbon footprint.

We design packaging with durability and reusability in mind, extending the useful life of each product. By creating packaging that can be used multiple times before disposal or recycling, we help reduce waste and conserve resources, contributing to a smaller environmental footprint.

We prioritize sourcing materials from local suppliers to reduce transportation distances and emissions. By keeping production and distribution close to home, we help cut down on the environmental impact associated with long-distance shipping. Local sourcing ensures a more sustainable and efficient supply chain.

We offer packaging made from eco-friendly, recyclable, and biodegradable materials that reduce reliance on virgin resources. By using sustainable materials, we help decrease the carbon emissions associated with material extraction and production. This ensures that your packaging has a smaller environmental impact from the very start.

Interested In Sustainable Packaging Solutions?

Discover the latest insights on sustainable packaging by exploring our blog, where we share tips and innovations to help businesses reduce their environmental impact. Stay informed about eco-friendly packaging solutions and learn how your company can make a difference through sustainability.

In the world of retail and e-commerce, packaging isn’t just about protecting products; it’s an essential part of the overall customer experience. One effective strategy to enhance this experience is tiered packaging. This approach involves offering premium packaging options for select products or customers, allowing you to cater to different preferences and elevate your brand’s image. In this detailed blog, we will explore the concept of tiered packaging and its benefits for businesses looking to provide a personalized and memorable unboxing experience. Understanding Tiered Packaging Tiered packaging is a strategic approach that involves creating multiple levels of packaging options, each catering to specific customer segments or product categories. These tiers typically include: Standard Packaging: The basic packaging option suitable for most products. It focuses on functionality and cost-efficiency. Premium Packaging: A higher-quality packaging option that adds a touch of luxury and sophistication to the unboxing experience. It often includes features like embossing, foiling, or special finishes. Custom Packaging: Tailored packaging solutions designed for specific products or occasions. Custom packaging can be highly personalized, reflecting the uniqueness of the product or event. Benefits of Tiered Packaging Tiered packaging offers numerous advantages for businesses looking to stand out in a competitive market: Personalization: By offering different packaging tiers, you can tailor the unboxing experience to the preferences and expectations of different customer segments. This personalization can create a stronger emotional connection with your brand. Brand Image: Premium and custom packaging options enhance your brand’s image, positioning it as upscale and attentive to detail. This can influence how customers perceive your products and brand. Customer Loyalty: Providing a premium unboxing experience can foster loyalty among your customers. They are more likely to return to a brand that consistently delivers a memorable and personalized experience. Increased Perceived Value: Premium packaging elevates the perceived value of your products. Customers are willing to pay more for items that come in high-quality packaging. Unboxing Excitement: Premium and custom packaging options create a sense of excitement during unboxing. This excitement can lead to positive unboxing videos and social media shares, providing free marketing and exposure. Versatility: Tiered packaging allows you to adapt to various occasions and product categories. You can offer different packaging options for regular product lines, seasonal promotions, limited-edition releases, and special events. Implementing Tiered Packaging Here are the key steps to implement tiered packaging effectively: Segment Your Audience: Identify distinct customer segments based on factors like purchasing behavior, demographics, or loyalty levels. Understand the unique preferences and expectations of each segment. Define Packaging Tiers: Create packaging tiers that align with your brand and the identified customer segments. Determine the features, materials, and finishes that differentiate each tier. Product Selection: Decide which products or product categories will be eligible for each packaging tier. Consider factors like product value, profit margin, and target audience. Pricing Strategy: Set pricing for each packaging tier. Ensure that the added cost of premium or custom packaging aligns with the perceived value it brings to the customer. Promotion and Communication: Promote your tiered packaging options through marketing channels and on your website. Clearly communicate the benefits of each tier and who it is designed for. Consistency: Maintain consistency in your packaging options and branding across all touchpoints, from the website to the unboxing experience. Consistency reinforces your brand identity. Conclusion Tiered packaging is a powerful strategy that allows businesses to offer a personalized and memorable unboxing experience while enhancing their brand image. By segmenting your audience, defining packaging tiers, selecting eligible products, setting pricing, and effectively promoting your options, you can create a packaging strategy that resonates with different customer segments and drives customer loyalty. Ultimately, tiered packaging is a valuable tool for businesses looking to stand out and create lasting impressions in today’s competitive market. If you are interested in tiered packaging solutions, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Oxygen and air exposure can adversely affect the quality, shelf life, and safety of your products. To ensure the integrity of your products and packaging, it’s essential to implement effective measures to protect against oxygen and air infiltration. In this blog, we will explore various strategies and best practices to help you safeguard your packaging against these environmental factors effectively. Understanding the Threat Before we delve into protective measures, it’s crucial to understand the potential risks associated with oxygen and air exposure: Oxidation: Exposure to oxygen can lead to oxidation, which can cause changes in color, flavor, and texture of food products, as well as the degradation of certain chemicals and pharmaceuticals. Spoilage: Oxygen can promote the growth of spoilage organisms and pathogens in perishable products, leading to product spoilage and safety concerns. Product Degradation: In some cases, oxygen exposure can trigger chemical reactions in products, causing them to deteriorate or lose efficacy. Protective Measures To safeguard your packaging against oxygen and air exposure, consider implementing the following protective measures: Oxygen Barrier Packaging Materials: Choose packaging materials with oxygen barrier properties. These materials prevent oxygen from permeating the package and coming into contact with the product. Common oxygen barrier materials include metallized films, aluminum foil, and certain plastics. Vacuum-Sealed Packaging: Utilize vacuum-sealing methods to remove air from the package before sealing it. Vacuum-sealed packaging creates an airtight environment that minimizes oxygen exposure. Nitrogen Flushing: Implement nitrogen flushing or gas flushing during the packaging process. This involves replacing the air inside the package with nitrogen or an inert gas to displace oxygen. Modified Atmosphere Packaging (MAP): Consider modified atmosphere packaging, where the atmosphere inside the package is modified to contain lower oxygen levels. This is common in the packaging of fresh produce and meats. Seal Integrity: Ensure that packaging seals are strong and airtight. Regular quality control checks should verify that no gaps or defects exist in the sealing process, preventing oxygen infiltration. Desiccants and Oxygen Absorbers: Include desiccants or oxygen absorbers inside the packaging. Desiccants remove moisture, which can contribute to oxidation, while oxygen absorbers remove oxygen, extending shelf life. Quality Control Checks: Conduct quality control checks to verify the effectiveness of oxygen protection measures. Use oxygen permeability testing to assess packaging materials. Barrier Films and Coatings: Apply oxygen barrier films or coatings to packaging materials. These films and coatings create an additional layer of protection against oxygen infiltration. Regulatory Compliance: Adhere to industry-specific and regulatory standards for products that require protection against oxygen exposure. Compliance ensures that your products meet safety and quality requirements. Vigilance and Continuous Improvement Protecting your packaging against oxygen and air exposure is an ongoing effort. Continuously assess your packaging solutions and gather feedback from consumers, retailers, and quality control personnel to identify any weaknesses or areas for improvement. Stay vigilant and proactive in addressing potential risks related to oxygen and air exposure. By implementing these strategies and maintaining a proactive approach to packaging protection, you can significantly reduce the risk of oxygen-related damage to your products, enhance their overall quality and safety, and ensure that your packaging maintains the highest standards of protection against these environmental factors. If you are interested in protection against oxygen and air exposure for your packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

When it comes to packaging liquids and semi-liquids, two popular options are spout pouches and traditional bottle packaging. Both have their advantages and disadvantages, making them suitable for various applications. In this detailed blog, we will conduct a comprehensive comparison of spout pouches and bottle packaging, exploring their features, benefits, drawbacks, and common use cases. By the end, you’ll have a clear understanding of which option might be the best fit for your specific product and branding needs. Features and Benefits of Spout Pouches Flexibility and Portability: Spout pouches are lightweight and flexible, making them easy to store and transport. They take up less space than rigid bottles, making them an excellent choice for on-the-go consumers. Customizable Design: Spout pouches offer a wide range of design possibilities. They can be customized with vibrant graphics, various shapes, and transparent windows, enhancing product visibility and shelf appeal. Reduced Environmental Impact: Spout pouches are often more eco-friendly than bottles. They require less material for production and transportation, contributing to reduced carbon footprint. Cost-Efficiency: Spout pouches can be cost-effective, particularly for large-volume orders. They save on material costs, storage space, and transportation expenses. Easy Dispensing: Spout pouches come with a built-in spout and cap, providing controlled and mess-free dispensing of liquids. This feature is especially valuable for products like baby food, sauces, and beverages. Drawbacks of Spout Pouches Limited Durability: While spout pouches are suitable for many applications, they may not provide the same level of durability and impact resistance as bottles. This can be a concern for products that require robust protection. Shelf Stability: For certain products that require extended shelf life or resistance to external factors like light and oxygen, bottles may offer better protection and preservation. Features and Benefits of Bottle Packaging Durability: Bottles, especially those made from glass or thick plastics, offer high durability and impact resistance. They are less likely to puncture or tear compared to spout pouches. Variety of Shapes and Sizes: Bottles come in various shapes, sizes, and materials, providing flexibility for different product types and branding needs. Premium Image: Glass bottles, in particular, convey a premium and upscale image for products like wine, spirits, and gourmet sauces. They are often associated with higher quality. Excellent Shelf Stability: Bottles can offer superior protection against external factors like light, oxygen, and moisture, ensuring product quality and shelf stability. Drawbacks of Bottle Packaging Environmental Impact: Traditional bottles can have a more substantial environmental impact due to the higher amount of material used and increased transportation costs. Weight and Transportation Costs: Bottles, especially glass ones, are heavier and bulkier, leading to higher transportation costs and potential breakage during transit. Limited Dispensing: Some bottle designs may not offer as convenient and controlled dispensing as spout pouches. Pouring liquids from bottles can be less precise and more prone to spills. Common Use Cases Spout Pouches: Spout pouches are commonly used for products such as baby food, fruit purees, energy drinks, liquid detergents, sauces, salad dressings, and personal care products. Bottle Packaging: Bottles are often chosen for beverages (water, juice, soda, alcoholic beverages), condiments (ketchup, mustard, mayonnaise), cooking oils, pharmaceuticals, and chemical products. Conclusion Choosing between spout pouches and bottle packaging depends on several factors, including product type, branding, environmental considerations, and consumer preferences. Spout pouches excel in terms of flexibility, customization, and eco-friendliness, while bottles offer durability, premium image, and excellent shelf stability. Ultimately, the decision should align with your specific product needs and overall packaging strategy, aiming to deliver the best possible consumer experience while meeting your business objectives. If you are interested in packaging for your beverages, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Beverage Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts