Sustainable Packaging

Explore our sustainable packaging products, including corrugated boxes, folding cartons, pouches, and stock packaging options. We offer eco-friendly materials and a variety of print and ink choices to fit your packaging needs. Choose from solutions designed to support sustainability and meet your business requirements.

Sustainable packaging refers to the use of materials and design methods that minimize environmental impact. This can include using recyclable or biodegradable materials, reducing excess packaging, and opting for renewable resources like paper, kraft, or corrugated materials. The goal is to reduce waste, conserve energy, and lessen the overall carbon footprint of packaging.

By choosing sustainable packaging, businesses help limit the negative effects of packaging waste on the environment. These products are often recyclable, compostable, or reusable, making them a more eco-friendly option. Sustainable packaging balances the need for protection and branding with the responsibility to preserve resources for future generations.

Our sustainable packaging products include custom corrugated boxes, folding cartons, pouches, and a variety of stock options. Each product is designed with eco-friendly materials to help reduce environmental impact while meeting your packaging needs.

Corrugated Boxes

- Regular slotted Container (RSC)

- Half Slotted Container (HSC)

- Full Overlap (FOL)

- Roll End Tuck Top (RETT/Mailer)

- Additional Box Styles

- Corrugated Inserts

Folding Cartons

- Straight Tuck End (STE)

- Reverse Tuck End (RTE)

- Full Seal

- Auto Bottom

- Chipboard Inserts

Pouches

- Stand Up

- Lay Flat

- Gusseted

- Retort

- Block Bottom

- Sachets

- Additional Pouch Styles

Stock Packaging Products

- Corrugated Packaging

- Shipping Boxes

- Chipboard Packaging

- Edge Protectors

- Mailers (Kraft)

- Kraft Tape

- Kraft Paper

At Brown Packaging, we prioritize eco-friendly packaging solutions that help reduce environmental impact. Our commitment to green packaging ensures that we provide sustainable materials, allowing you to make responsible choices for your business and the planet.

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

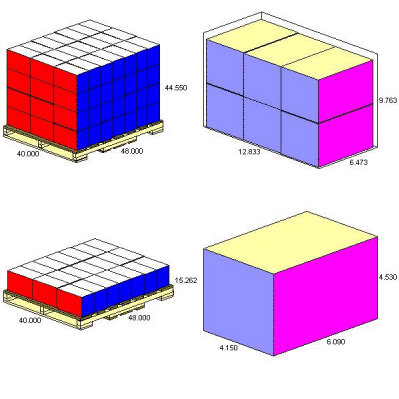

We provide packaging solutions designed to help reduce your carbon footprint through eco-friendly production, efficient shipping, and sustainable materials. From pallet optimization to energy-efficient manufacturing, our approach ensures that your packaging minimizes environmental impact at every stage.

Our custom structural design services allow us to minimize material use without compromising protection. By optimizing the design for strength and efficiency, we help you reduce excess packaging and the environmental costs associated with waste. Smarter packaging design means a lower carbon footprint overall.

With CAPE software, we optimize pallet configurations to maximize space and load efficiency. This results in fewer trips and lower fuel usage during transportation, reducing your carbon footprint. By making the most of every pallet, we help you achieve more eco-friendly logistics.

We offer digital samples, eliminating the need for multiple physical prototypes, which reduces waste and energy use in production. By creating virtual models, we help you save resources while speeding up the design process. This eco-friendly approach helps minimize the carbon footprint of packaging development.

We focus on eco-friendly production processes that minimize waste and reduce energy consumption. By using sustainable materials and optimizing manufacturing efficiency, we help lower the carbon footprint of your packaging. This commitment to sustainable production ensures a smaller environmental impact from the start.

Our lightweight and efficient packaging solutions help reduce transportation emissions by maximizing space and minimizing weight. By designing packaging that is easy to transport, we help your business cut down on fuel consumption and overall shipping costs, contributing to a reduced carbon footprint.

We design packaging with durability and reusability in mind, extending the useful life of each product. By creating packaging that can be used multiple times before disposal or recycling, we help reduce waste and conserve resources, contributing to a smaller environmental footprint.

We prioritize sourcing materials from local suppliers to reduce transportation distances and emissions. By keeping production and distribution close to home, we help cut down on the environmental impact associated with long-distance shipping. Local sourcing ensures a more sustainable and efficient supply chain.

We offer packaging made from eco-friendly, recyclable, and biodegradable materials that reduce reliance on virgin resources. By using sustainable materials, we help decrease the carbon emissions associated with material extraction and production. This ensures that your packaging has a smaller environmental impact from the very start.

Interested In Sustainable Packaging Solutions?

Discover the latest insights on sustainable packaging by exploring our blog, where we share tips and innovations to help businesses reduce their environmental impact. Stay informed about eco-friendly packaging solutions and learn how your company can make a difference through sustainability.

As the packaging industry shifts toward more sustainable and efficient solutions, folding cartons are set to play a significant role in 2025. From eco-friendly materials to smart packaging designs, brands are leveraging folding cartons to meet evolving consumer expectations and regulatory demands. Below are the top folding carton trends to watch for in 2025: Sustainable Materials Advanced Digital Printing Custom Design and Personalization Minimalist and Clean Aesthetic Enhanced Durability and Protection Smart and Connected Packaging Flexible Packaging Solutions Recyclable and Compostable Cartons Lightweight and Efficient Designs Cost-Effective Packaging Sustainable Materials Folding cartons in 2025 will prioritize eco-friendly materials, including recycled paperboard and plant-based alternatives. Brands are expected to shift toward FSC-certified materials and other renewable sources, reducing their environmental impact while still offering durable packaging solutions. Advanced Digital Printing With the advancement of digital printing technology, brands will be able to create intricate, high-quality designs on folding cartons more cost-effectively. In 2025, short-run digital printing will become more accessible, allowing for rapid production without sacrificing detail or color, and enabling small businesses to customize their packaging easily. Custom Design and Personalization Consumers increasingly expect personalized experiences, and folding cartons will be a key player in delivering on this expectation. Custom designs, limited-edition packaging, and personalized messaging will be central trends, helping brands create unique, memorable unboxing experiences. Minimalist and Clean Aesthetic Simplicity in packaging design continues to be a dominant trend. The minimalist approach, with clean lines and neutral colors, reflects a focus on sustainability and appeals to consumers seeking eco-friendly, waste-conscious brands. Expect folding cartons with less ink and fewer materials for a streamlined, eco-conscious look. Enhanced Durability and Protection As more products are being shipped globally, folding cartons will evolve to offer better protection without adding excess material. By integrating reinforced corners and innovative structural designs, folding cartons will ensure that fragile items are protected during transit while maintaining sustainability goals. Smart and Connected Packaging Smart packaging will also play a role in folding cartons, with the integration of QR codes and NFC tags allowing consumers to engage with the product or brand directly through their smartphones. This tech will provide information on product authenticity, freshness, and even sustainability efforts, giving consumers a more interactive experience. Flexible Packaging Solutions The demand for more flexible folding carton solutions is growing. In 2025, expect to see more cartons designed for multi-use purposes, such as packaging that can transform into a display or storage container, giving the product’s packaging a second life and minimizing waste. Recyclable and Compostable Cartons Recyclability and compostability will remain top priorities in folding carton trends for 2025. More brands will move towards mono-material designs that enhance recyclability or use compostable materials that break down easily in commercial or home composting environments, ensuring a minimal environmental footprint. Lightweight and Efficient Designs Lightweight folding cartons will grow in popularity as companies seek to reduce transportation costs and emissions. Cartons that use less material but maintain strength and durability will be highly valued by brands focused on optimizing shipping while still protecting their products. Cost-Effective Packaging As the cost of raw materials fluctuates, brands will increasingly seek cost-effective folding carton solutions that balance affordability with sustainability. Innovations in production efficiency and material sourcing will allow companies to maintain high-quality packaging without increasing costs significantly. Folding cartons are evolving to meet the demands of a more sustainability-focused, cost-conscious market. In 2025, businesses that adopt these trends will be better positioned to align with consumer preferences and regulatory requirements while maintaining the flexibility and durability needed for their products. If you’re interested in folding cartons for 2025, whether they are custom or stock, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Folding Carton Facebook Twitter LinkedIn Pinterest Relevant Posts

In the business landscape, the significance of packaging extends far beyond mere aesthetics or basic product protection. It plays a crucial role in branding, customer experience, and significantly impacts the overall cost structure of a product. Understanding the various elements that drive packaging costs is essential for any business looking to optimize expenses while maintaining quality and appeal. This blog post delves into the most influential factors contributing to your packaging’s costs, ranked by their potential impact. Material Choice At the top of the list is the choice of materials used for packaging. The cost implications here are substantial, as materials not only dictate the cost per unit but also affect transportation, storage, and even waste management expenses. Types of Materials: Options range from economical cardboard to more expensive plastics or metals. Quality and Durability: Higher quality materials that offer better protection or aesthetic appeal often come at a higher cost. Sustainability: Eco-friendly materials can be more expensive but may reduce environmental fees and appeal to a green-conscious market. Design Complexity and Customization The design intricacies of your packaging play a significant role in determining the cost. More complex designs with custom shapes, sizes, or functionality typically require more expensive production processes. Custom Molds and Dies: Unique shapes might need custom production equipment. Printing and Graphics: High-quality prints, multiple colors, and intricate designs add to the production costs. Structural Design: Complex structures that require additional engineering or testing can increase costs. Production Volume The quantity of packaging produced has a direct impact on cost per unit due to economies of scale. Higher Volume, Lower Cost Per Unit: Bulk production usually results in lower costs per unit due to more efficient use of materials and machinery. Small Runs: Smaller production runs can be significantly more expensive per unit due to setup costs and less efficient use of resources. Manufacturing Techniques The chosen method of manufacturing is another critical factor. Advanced techniques like automation can offer cost savings at scale but require significant upfront investment. Manual vs. Automated Processes: Automation reduces labor costs but increases initial investment. Production Speed: Faster production methods can reduce costs but might require more advanced, expensive machinery. Packaging Functionality and Performance The functional requirements of packaging, especially for products that need special handling, can dramatically influence costs. Protection Requirements: More robust packaging for fragile items increases material and design costs. Shelf Life Extension: Packaging that prolongs product life, like vacuum sealing, can be more expensive. Transportation and Storage The cost of shipping and storing packaging materials and the final packaged product is often overlooked but vital. Size and Weight: Bulky or heavy packaging leads to higher transportation costs. Storage Needs: Larger or more sensitive packaging can require more expensive storage solutions. Environmental Compliance and Sustainability Initiatives Adhering to environmental regulations and implementing sustainability initiatives can influence packaging costs. Compliance Costs: Meeting environmental standards can require more expensive materials or processes. Sustainability Programs: Initiatives like recycling programs or the use of biodegradable materials might increase costs but can offer long-term brand benefits. Conclusion In conclusion, packaging costs are influenced by a complex interplay of material choices, design intricacies, production volumes, manufacturing techniques, functionality requirements, logistics, and environmental considerations. Businesses need to carefully evaluate these factors to strike the right balance between cost, quality, functionality, and sustainability. By understanding and optimizing these key influencers, companies can make informed decisions that align with their financial goals and brand values. If you are interested in cost efficient packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Once the design and material selection for a Point of Purchase (POP) display are locked in, the project moves into the critical production phase. This stage is where your concept is transformed into a tangible product ready for retail environments. The key to successful production lies in stringent quality control measures and a well-coordinated manufacturing process. This blog outlines the essential steps and considerations for the production phase of POP displays, ensuring each unit is built to meet both aesthetic and functional standards. Streamlining the Manufacturing Process Setting Up the Production Line The first step in the production phase is setting up the manufacturing line. This setup should be optimized based on the design specifications and material requirements of the POP display. Efficient line setup helps minimize production time and cost, ensuring that each component is assembled correctly and efficiently. Integrating Technology and Automation Where possible, integrating advanced manufacturing technologies and automation can enhance precision and speed in the production process. Automation can be particularly beneficial in producing components that require consistent replication of detailed designs, contributing to uniformity and quality across all units. Implementing Quality Control Measures Developing Quality Standards Before production begins, establish clear quality standards that align with the display’s design and functionality goals. These standards should cover all aspects of the display, including material integrity, color accuracy, structural stability, and overall finish. Continuous Quality Monitoring Implement continuous quality monitoring throughout the production process. This involves regular inspections and testing of the displays at various stages of manufacturing. By catching defects or deviations early, you can prevent issues that might compromise the final product’s effectiveness. Feedback Loop with Design and Materials Teams Maintain a feedback loop with the design and materials teams. This collaboration ensures that any potential issues identified during production can be traced back to design or material choices and addressed promptly, preventing recurrence. Ensuring Compliance with Specifications Adherence to Design Specifications It’s crucial that the manufacturing process adheres strictly to the agreed-upon design specifications. This adherence prevents variations that could affect how the display performs in its intended retail environment and ensures that all functional and aesthetic elements are preserved. Alignment with Material Specifications Similarly, ensure that the materials used in production match the specifications decided during the planning phase. Using the correct materials affects not only the display’s look and feel but also its durability and impact in a store setting. Preparing for Post-Production Assembly and Pre-Installation Checks If the display requires assembly post-production, conduct thorough checks to ensure all parts fit together correctly and that assembly is as straightforward as possible. These checks can help streamline the installation process later on. Final Quality Assurance Before the displays are shipped, a final quality assurance check should be conducted. This final review ensures that every display unit meets your brand’s quality standards and is ready for deployment without needing further modifications. Conclusion The production phase is where your POP display comes to life. By focusing on efficient production setups, stringent quality control, and strict adherence to specifications, you can ensure that the manufactured displays meet the desired standards. Thorough planning and monitoring during this phase lay the groundwork for effective POP displays that attract attention and withstand the demands of the retail environment, ultimately driving sales and enhancing brand presence. If you are interested in POP displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Display Facebook Twitter LinkedIn Pinterest Relevant Posts