Sustainable Packaging

Explore our sustainable packaging products, including corrugated boxes, folding cartons, pouches, and stock packaging options. We offer eco-friendly materials and a variety of print and ink choices to fit your packaging needs. Choose from solutions designed to support sustainability and meet your business requirements.

Sustainable packaging refers to the use of materials and design methods that minimize environmental impact. This can include using recyclable or biodegradable materials, reducing excess packaging, and opting for renewable resources like paper, kraft, or corrugated materials. The goal is to reduce waste, conserve energy, and lessen the overall carbon footprint of packaging.

By choosing sustainable packaging, businesses help limit the negative effects of packaging waste on the environment. These products are often recyclable, compostable, or reusable, making them a more eco-friendly option. Sustainable packaging balances the need for protection and branding with the responsibility to preserve resources for future generations.

Our sustainable packaging products include custom corrugated boxes, folding cartons, pouches, and a variety of stock options. Each product is designed with eco-friendly materials to help reduce environmental impact while meeting your packaging needs.

Corrugated Boxes

- Regular slotted Container (RSC)

- Half Slotted Container (HSC)

- Full Overlap (FOL)

- Roll End Tuck Top (RETT/Mailer)

- Additional Box Styles

- Corrugated Inserts

Folding Cartons

- Straight Tuck End (STE)

- Reverse Tuck End (RTE)

- Full Seal

- Auto Bottom

- Chipboard Inserts

Pouches

- Stand Up

- Lay Flat

- Gusseted

- Retort

- Block Bottom

- Sachets

- Additional Pouch Styles

Stock Packaging Products

- Corrugated Packaging

- Shipping Boxes

- Chipboard Packaging

- Edge Protectors

- Mailers (Kraft)

- Kraft Tape

- Kraft Paper

At Brown Packaging, we prioritize eco-friendly packaging solutions that help reduce environmental impact. Our commitment to green packaging ensures that we provide sustainable materials, allowing you to make responsible choices for your business and the planet.

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

We provide packaging solutions designed to help reduce your carbon footprint through eco-friendly production, efficient shipping, and sustainable materials. From pallet optimization to energy-efficient manufacturing, our approach ensures that your packaging minimizes environmental impact at every stage.

Our custom structural design services allow us to minimize material use without compromising protection. By optimizing the design for strength and efficiency, we help you reduce excess packaging and the environmental costs associated with waste. Smarter packaging design means a lower carbon footprint overall.

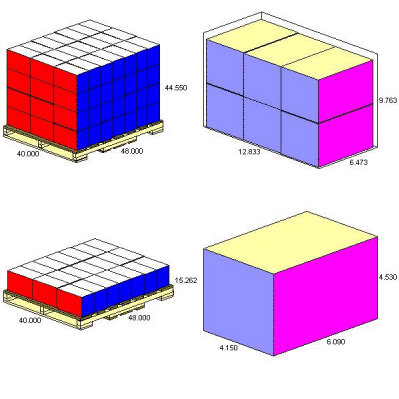

With CAPE software, we optimize pallet configurations to maximize space and load efficiency. This results in fewer trips and lower fuel usage during transportation, reducing your carbon footprint. By making the most of every pallet, we help you achieve more eco-friendly logistics.

We offer digital samples, eliminating the need for multiple physical prototypes, which reduces waste and energy use in production. By creating virtual models, we help you save resources while speeding up the design process. This eco-friendly approach helps minimize the carbon footprint of packaging development.

We focus on eco-friendly production processes that minimize waste and reduce energy consumption. By using sustainable materials and optimizing manufacturing efficiency, we help lower the carbon footprint of your packaging. This commitment to sustainable production ensures a smaller environmental impact from the start.

Our lightweight and efficient packaging solutions help reduce transportation emissions by maximizing space and minimizing weight. By designing packaging that is easy to transport, we help your business cut down on fuel consumption and overall shipping costs, contributing to a reduced carbon footprint.

We design packaging with durability and reusability in mind, extending the useful life of each product. By creating packaging that can be used multiple times before disposal or recycling, we help reduce waste and conserve resources, contributing to a smaller environmental footprint.

We prioritize sourcing materials from local suppliers to reduce transportation distances and emissions. By keeping production and distribution close to home, we help cut down on the environmental impact associated with long-distance shipping. Local sourcing ensures a more sustainable and efficient supply chain.

We offer packaging made from eco-friendly, recyclable, and biodegradable materials that reduce reliance on virgin resources. By using sustainable materials, we help decrease the carbon emissions associated with material extraction and production. This ensures that your packaging has a smaller environmental impact from the very start.

Interested In Sustainable Packaging Solutions?

Discover the latest insights on sustainable packaging by exploring our blog, where we share tips and innovations to help businesses reduce their environmental impact. Stay informed about eco-friendly packaging solutions and learn how your company can make a difference through sustainability.

When it comes to pouch packaging, the material and finish play a crucial role in the overall functionality, aesthetics, and consumer appeal of the product. These elements are not just about visual charm; they impact durability, product preservation, and brand perception. This blog post aims to provide an in-depth guide on how to consider material and finish in the design of pouch packaging. Understanding the Significance of Material and Finish in Pouch Packaging The choice of material and finish for pouch packaging is pivotal. It’s not just a matter of containing the product; it’s about preserving its quality, ensuring usability, and creating an appealing presentation that resonates with consumers. Choosing the Right Material Assess Product Needs: Perishability: For perishable goods, consider barrier properties like oxygen and moisture resistance. Weight and Form: Heavier items or liquids require stronger, more durable materials. Chemical Compatibility: Ensure the material is compatible with your product to prevent reactions or degradation. Sustainability Considerations: Eco-Friendly Options: Explore materials that are recyclable, biodegradable, or made from renewable resources. Lifecycle Impact: Consider the environmental impact of the material throughout its lifecycle, from production to disposal. Cost-Effectiveness: Balance the cost of the material with the value it adds in terms of functionality and consumer appeal. Selecting the Appropriate Finish Enhancing Aesthetics: Matte vs. Glossy: Matte finishes offer a sophisticated, modern look, while glossy finishes are bright and eye-catching. Choose based on your brand image and customer preferences. Texture: Textured finishes can provide a unique tactile experience, adding to the perceived value of the product. Functional Benefits: Protection from Damage: Finishes can offer additional protection against physical damage, UV light, and moisture. Visibility and Legibility: Consider how the finish affects the visibility of the packaging contents and the legibility of printed information. Printing and Branding: Print Compatibility: Ensure the finish works well with your chosen printing method for clear, vibrant graphics. Brand Consistency: The finish should align with your overall branding strategy, reinforcing brand identity. Innovative Material and Finish Combinations Windowed Pouches: Combine opaque materials with clear sections for product visibility. Metallic Effects: Use materials with metallic finishes for a premium look, ideal for luxury products. Consumer Experience and Interaction Ease of Use: Consider how the material and finish affect the opening, closing, and overall handling of the pouch. Unboxing Experience: The material and finish can significantly impact the unboxing experience, crucial for e-commerce products. Regulatory Compliance and Safety Ensure that the chosen materials and finishes comply with industry-specific regulations, particularly for food and pharmaceutical products. Testing and Feedback Conduct market tests and gather consumer feedback to refine your choice of materials and finishes. Conclusion The material and finish of pouch packaging are more than superficial choices; they are integral components of the product’s marketability and consumer experience. By thoughtfully considering these elements, businesses can create packaging that not only stands out on the shelf but also meets the functional demands of the product and the environmental considerations of the market. In the ever-evolving world of packaging, the right material and finish can make all the difference in capturing and retaining consumer interest. If you are interested in pouch packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Subscribe To Our Newsletter Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability By submitting your information, you agree to our terms and conditions and privacy policy. Custom Pouches Facebook Twitter LinkedIn Pinterest Relevant Posts

With tariffs set to reshape the U.S. packaging industry in 2025, packaging buyers must understand their potential benefits and challenges. Tariffs aim to encourage domestic sourcing and manufacturing, but their effects can be complex. This blog examines the pros and cons of tariffs for packaging buyers, offering a neutral and informative perspective to help navigate the changing landscape. What Are Tariffs and How Do They Affect Packaging? Tariffs are taxes imposed on imported goods, designed to incentivize businesses to source domestically. For the packaging industry, this can lead to increased costs for materials and finished products sourced internationally. At the same time, tariffs may promote local manufacturing and strengthen domestic supply chains. The Pros of Tariffs on Packaging Encourages Domestic Manufacturing Tariffs make imported goods more expensive, driving demand for U.S.-produced materials and packaging products. Benefits for Buyers: Strengthened local supply chains reduce dependency on international markets. Shorter transportation distances can improve delivery reliability and speed. Opportunities to work with domestic suppliers who align with sustainability and quality standards. Reduces Exposure to Global Disruptions The COVID-19 pandemic and other global events highlighted vulnerabilities in international supply chains. Tariffs encourage buyers to source locally, mitigating risks from international shipping delays or geopolitical tensions. Drives Investment in Innovation As demand for domestic packaging grows, U.S. manufacturers may invest in new technologies and materials to remain competitive. Examples of Innovation: Development of cost-effective, eco-friendly packaging options. Automation to improve production efficiency and reduce lead times. Potential Environmental Benefits Local sourcing reduces the need for long-distance shipping, which can lower carbon emissions associated with packaging production and transportation. The Cons of Tariffs on Packaging Increased Costs The most immediate impact of tariffs is higher prices for imported materials and products. These costs can affect buyers in several ways: Material Price Increases: Tariffs on imported paperboard, plastics, or aluminum can drive up the cost of packaging solutions like corrugated boxes, flexible films, and beverage cans. Pass-Through Costs: Suppliers may pass tariff-related expenses onto buyers, increasing procurement costs. Supply Chain Bottlenecks The shift to domestic sourcing can create short-term challenges as manufacturers ramp up to meet increased demand. Potential Issues: Limited production capacity among domestic suppliers. Longer lead times due to initial supply shortages. Limited Supplier Options In some cases, buyers may struggle to find domestic suppliers offering the same quality, pricing, or product variety as their international counterparts. Complexity in Procurement Tariffs add an extra layer of complexity to procurement processes, requiring buyers to: Monitor tariff changes and their impacts. Evaluate the cost-benefit of domestic vs. international sourcing. Navigate customs regulations and compliance requirements for any remaining imports. Balancing the Pros and Cons Packaging buyers can weigh the benefits and drawbacks of tariffs by aligning their sourcing strategies with business goals. Consider these key factors: When Tariffs Can Be a Positive Change: Your business values a resilient, local supply chain. Sustainability is a priority, and reducing transportation emissions aligns with your goals. You’re looking to foster long-term partnerships with domestic manufacturers. When Tariffs May Pose Challenges: Your packaging relies on specialized materials or products not widely available in the U.S. Cost increases would significantly impact your pricing or profitability. You operate in an industry where margins are already tight. Preparing for Tariffs in the Packaging Industry To navigate the impact of tariffs effectively, packaging buyers can take proactive steps to mitigate challenges while capitalizing on opportunities: Evaluate Supplier Relationships: Build partnerships with domestic manufacturers to ensure reliable sourcing. Invest in Cost Management: Optimize packaging designs and explore alternative materials to reduce expenses. Stay Updated: Monitor tariff policies and industry trends to make informed decisions. Leverage Technology: Use supply chain management tools to enhance forecasting, inventory management, and sourcing strategies. Final Thoughts Tariffs on packaging present a mixed picture for buyers, offering both opportunities and obstacles. While they can drive innovation and strengthen domestic supply chains, they also introduce cost pressures and logistical challenges. By understanding the pros and cons of tariffs and preparing strategically, packaging buyers can adapt to these changes while maintaining operational efficiency. If you are interested in maximizing the benefits of tariffs on your packaging and limiting the challenges, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In the competitive landscape of product marketing, packaging is not just a vessel for your products; it’s a crucial communication channel. The way a brand utilizes messaging and communication on packaging can significantly influence consumer perception, brand recall, and ultimately, purchasing decisions. This blog post explores how brands can effectively leverage the power of messaging and communication on their packaging to engage customers and enhance brand identity. The Role of Messaging in Packaging Packaging is often the first point of physical contact between a consumer and a product. The messages conveyed through packaging can range from brand values and product benefits to user instructions and sustainability claims. Effective messaging on packaging can educate, persuade, and create an emotional connection with the consumer. Crafting Effective Messaging Clarity and Conciseness: Packaging has limited space, so messages should be clear and to the point. Overcrowding the package with too much text can overwhelm the consumer and dilute key messages. Relevance and Resonance: The messaging should resonate with the target audience. Understanding consumer needs, preferences, and pain points is crucial in crafting messages that connect and engage. Brand Voice Consistency: The tone, style, and language used on packaging should be consistent with the overall brand voice. This consistency reinforces brand identity and aids in building brand trust. Strategic Placement of Messages Front and Center: Key messages, like the product name, unique selling proposition (USP), or a call to action, should be prominently placed on the front of the package. This is what consumers see first and what captures their attention. Secondary Information: Other important information, such as product details, ingredients, and usage instructions, can be placed on the sides or back of the package. This placement allows interested consumers to learn more without cluttering the primary display area. Leveraging Visual Elements for Communication Typography and Color: The choice of fonts and colors can significantly impact the readability and emotional impact of your messages. Bold fonts and contrasting colors can make key messages stand out. Graphics and Icons: Visuals can often communicate messages more effectively than words. Using icons, infographics, or illustrations can help convey complex information in an easily digestible format. Incorporating Interactive Elements QR Codes and AR: Modern packaging often includes QR codes or augmented reality (AR) elements. These can link consumers to digital content, providing a deeper engagement with the brand and detailed product information. Social Media Prompts: Encouraging consumers to engage with the brand on social media through packaging can build a community and foster brand loyalty. Sustainability Messaging Eco-friendly Claims: As consumers become more environmentally conscious, including messages about the sustainability of the packaging and product can be a significant selling point. Transparency: Be transparent about your environmental claims. Misleading or vague claims can lead to consumer mistrust. Regulatory Compliance and Legal Considerations Compliance: Ensure that all messaging on packaging complies with industry-specific regulations, especially in sectors like food, beverages, and pharmaceuticals. Truthfulness: All claims made on packaging should be accurate and verifiable to maintain credibility and avoid legal issues. Testing and Feedback Consumer Testing: Conducting market research and consumer testing can provide valuable insights into how effective your packaging messaging is and what improvements can be made. Iterative Process: Continuously refine your packaging messages based on consumer feedback and market trends. Conclusion Effective messaging and communication on packaging are about striking the right balance between informing, engaging, and persuading your target audience. It’s an integral part of the marketing strategy that can significantly influence the consumer’s journey from awareness to purchase. In an era where consumers are bombarded with choices, packaging that communicates effectively can make your product stand out and resonate with the intended audience. Remember, in the world of packaging, a message well conveyed is a product well perceived. If you are interested custom packaging solutions to communicate effectively with your audience, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts