Stock Packaging

We supply businesses with a wide selection of essential packaging, shipping, and warehouse supplies. Get any standard packaging product by dimension or style from boxes, tubes, tapes, labels, and more. If you are unsure on what type of packaging you will need, then contact us for an expert consultation.

Stock packaging refers to pre-made, ready-to-ship packaging solutions like corrugated boxes, mailers, and protective materials that are designed to meet a wide range of standard needs across shipping, retail, and storage. Unlike custom packaging, stock options offer quick availability and reliable protection without the need for extensive design or production time, making them ideal for businesses needing efficient, high-quality solutions with fast lead times.

At Brown Packaging, we focus on providing durable, performance-driven stock packaging that supports our clients’ operational needs. Our stock products are sourced to ensure consistent quality and cost-effectiveness, offering a practical solution to keep operations running smoothly and on schedule. With an emphasis on reliability, we help our clients quickly access packaging solutions that meet their specific needs while maintaining quality across every order.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about custom packaging by reading our blog posts on new and trending topics.

Corrugated bin boxes are widely used for storage and organization, especially in warehouses and retail settings. When used and stacked properly, they offer an efficient way to store small items, parts, or products. However, if you’re not careful, stacking them haphazardly can lead to instability and potential damage to both the boxes and their contents. Here’s a step-by-step guide to stack corrugated bin boxes safely and efficiently. Step 1. Start with a Strong Foundation Before you begin stacking, ensure you have a firm and level surface. This could be a sturdy table, a shelving unit, or a flat area of the floor. A good foundation ensures the boxes will not tip over or collapse under the weight. Step 2. Inspect Your Boxes Examine each box for signs of wear, tear, or damage. A damaged box might not have the structural integrity to hold weight or stay upright, especially when stacked. Step 3. Choose the Right Size Start with the largest and sturdiest boxes at the bottom. As you build up, the boxes should become progressively smaller. This creates a pyramid-like structure, ensuring stability. Step 4. Mind the Weight Be mindful of the weight you’re putting into each box. A heavier box placed on top of a lighter box can lead to a collapse. Best rule of thumb, is placing the heavier boxes on bottom with the lighter boxes on top. Step 5. Align the Edges When stacking, make sure the edges of the boxes line up as precisely as possible. This ensures that the weight is distributed evenly across the surface of the box below and reduces the risk of tipping. Step 6. Avoid Overloading It’s essential to avoid overstuffing the boxes. An overstuffed box can bulge, making it uneven and unstable when stacked. It can also lead to the contents spilling out or the box tearing. Step 7. Leave Some Space If you’re stacking boxes on a shelf, make sure there’s a little space between the top of the highest box and the shelf above. This not only makes it easier to retrieve boxes but also ensures that there’s adequate airflow, reducing the risk of moisture buildup, which can weaken corrugated boxes. Step 8. Label Clearly Label each box clearly on the front and sides, so you can quickly identify its contents without having to unstack or move multiple boxes. Step9. Regularly Check for Stability Every so often, give your stack of boxes a gentle push to ensure they’re still stable. Over time, the weight distribution inside boxes might change, or the boxes themselves could wear down, impacting their stability. Step 10. Replace Worn Out Boxes If a box shows signs of wear or begins to sag, replace it. Regularly rotating out old or worn boxes ensures the entire stack remains stable and that your items are safe. Step 11. Use Dividers if Needed If you’re storing many small items in one box, use dividers. These can prevent items from shifting too much, which can lead to an uneven distribution of weight. Final Thoughts Corrugated bin boxes are a versatile and eco-friendly solution for storage needs. By following these stacking guidelines, you can ensure the safety and longevity of both your boxes and their contents. Always prioritize stability and avoid the temptation to stack too high – it’s better to have two stable shorter stacks than one towering, unstable one. Safe stacking! If you are interested in corrugated bin boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Corrugated Bin Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

The visual appeal of a product often determines its success in the market. In today’s competitive retail environment, innovative packaging designs have become a crucial aspect of the marketing mix. One of the increasingly popular methods used to enhance product presentation is thermoform packaging. This blog post delves into the world of thermoform packaging, exploring its potential to revolutionize product presentation. What is Thermoform Packaging? Thermoform packaging is a type of packaging that involves heating plastic sheets until they are pliable, then molding them into specific shapes to contain, protect, and display a product. Once the plastic cools, it retains the desired form, providing a durable and aesthetically pleasing package. The Impact of Packaging on Product Presentation The role of packaging extends beyond product protection. It serves as a silent salesperson, speaking volumes about the product’s quality and value. An appealing packaging design can captivate consumers, facilitating brand recognition and fostering customer loyalty. Creating a Unique Product Image Thermoform packaging can enhance the image of a product. Its adaptability allows businesses to create unique, brand-specific designs. This personalization sets products apart, offering a competitive edge in crowded marketplaces. Enhancing Visibility and Accessibility Transparent thermoform packaging enables customers to see the actual product, adding a layer of transparency and trust. By improving product visibility, it boosts consumer confidence and increases the chances of purchase. Thermoform Packaging: A Revolution in Product Presentation Thermoform packaging provides opportunities for manufacturers to reimagine their product presentation and develop packaging designs that truly reflect their brand identity. Here are some ways that thermoform packaging revolutionizes product presentation: Customizable Designs Thermoform packaging is exceptionally customizable, with the ability to conform to virtually any shape or size. This flexibility enables brands to design innovative packaging that aligns with their product and brand image. Unique and intricate designs can be realized through thermoforming, allowing products to stand out on the shelf. Material and Cost Efficiency Thermoform packaging uses plastic efficiently, reducing material waste. It also has a lower tooling cost compared to other types of packaging, such as injection molding. This cost-effectiveness is beneficial for businesses seeking to improve their packaging without significantly increasing their overheads. Environmentally Friendly Options As sustainability becomes a more significant consumer concern, companies can choose eco-friendly materials for thermoform packaging. Some thermoform plastics are recyclable, and biodegradable options are available as well. Enhanced Product Protection Thermoform packaging not only boosts product presentation but also provides robust protection. The molded plastic can cushion products during transport and minimize damage, ensuring the product reaches the customer in pristine condition. Case Studies of Thermoform Packaging Revolutionizing Product Presentation To truly grasp the transformative power of thermoform packaging, let’s look at a couple of case studies: Consumer Electronics The electronics industry is often the front runner in utilizing thermoform packaging. With its ability to create tailored compartments for individual components, thermoform packaging offers unrivaled protection and an impressive unboxing experience, strengthening the brand’s image. Food Industry In the food industry, thermoform packaging enhances product presentation while maintaining freshness and safety. The visual appeal of clear thermoform packages enables consumers to view the product directly, influencing their buying decision positively. The Future of Product Presentation Thermoform packaging has proven itself as a powerful tool for product presentation. As technology advances and more sustainable materials become available, we can expect to see more innovative and eco-friendly thermoform packaging solutions in the future. From boosting brand image to protecting products and providing cost-effective solutions, thermoform packaging is indeed revolutionizing the way products are presented. By embracing this technology, brands can deliver a more engaging and memorable consumer experience, ultimately driving sales and growth. If you are interested in thermoform packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Thermoform Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

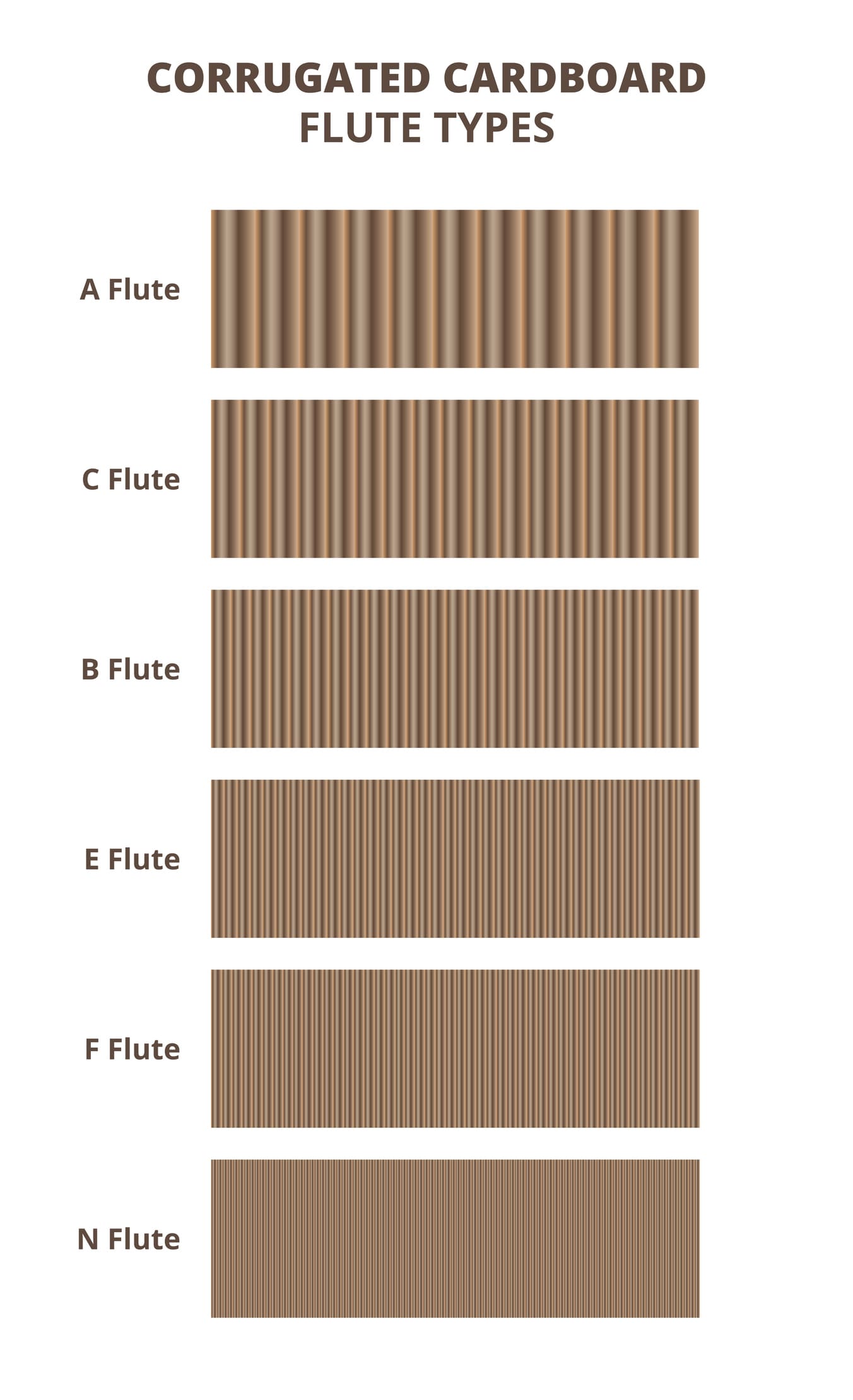

At a cursory glance, the humble cardboard box might seem like a straightforward item, yet it’s far more intricate and sophisticated than it initially appears. Deceptively simple, the construction of these boxes features numerous structural components that provide robustness, protection, and insulation, while offering an invaluable canvas for brand promotion. One of these often-overlooked components is the corrugated flute, a critical aspect of cardboard packaging that plays a vital role in the design and functionality of the box. This comprehensive guide will take a deep dive into corrugated flutes and their role in the packaging industry. Decoding Corrugated Flutes Corrugated flutes might escape the naked eye at first, but these wave-like patterns, nestled between the liner layers, form the very backbone of corrugated packaging. Integral to the composition of cardboard boxes, they turn these packages into sturdy containers, making them some of the most reliable methods for shipping and storage. Key Roles of Corrugated Flutes Corrugated flutes are much more than just layers of corrugated material. They play a central role in providing corrugated packaging with additional insulation and protection layers. Acting as the structural skeleton of the packaging, these flutes make the package crush-proof and puncture-proof, making it possible for boxes to bear the weight of heavy items without giving way or collapsing. To further understand the role of these flutes, let’s examine them in a typical shipping scenario. Packages often undergo considerable stress during transit, such as pressure from other boxes, jostling, or even puncture risks. The flutes within the corrugated box provide a cushioning effect that absorbs these shocks and helps protect the contents of the box. As a result, whether you’re shipping delicate glassware or weighty books, you can be confident that your items are secure within their corrugated packaging. A Detailed Look at the Five Types of Corrugated Flutes Not all corrugated flutes are created equal. The packaging industry employs five primary types of flutes, each serving specific needs and offering different benefits. Let’s explore these types in more detail: A Flutes With a thickness of approximately 5 millimeters or ¼ inch, the A flute is the thickest type available. Around 36 of these flutes can be found within a single linear foot of packaging, resulting in a highly robust structure for heavier items and excellent cushioning for delicate contents. A flute’s larger size provides optimal strength and compression properties, making it an excellent choice for products that require more support or have a higher risk of breakage. It’s no surprise then that A flutes are often used in packaging electronics, appliances, glass items, and other similar products. B Flutes The B flute, about 3.2 millimeters or ⅛ inch thick, falls into the mid-range category. With about 49 flutes per linear foot, it offers considerable crush and puncture resistance. B flutes provide an excellent surface for printing words, graphics, and logos directly onto the corrugated cardboard. Thanks to its combination of stiffness and compactness, the B flute is commonly used in retail packaging for items like canned goods. It is also commonly used in stand-up displays and for smaller boxes requiring a more refined print. Die cut boxes, generally use B – flute, as relatively small flute thickness helps when there a several scores and folds. C Flutes Being the second-thickest, C flutes measure around 3.2 millimeters or 11/64 inches in thickness, and about 41 flutes fit within a single linear foot. These flutes are ideal for shipping boxes due to their excellent resistance to crushing and compression. A C flute’s excellent stacking strength and printing capabilities make it a popular choice for transporting heavier products. Whether you’re moving a kitchen appliance or a batch of fresh produce, C flutes offer the durability and support needed. C- flute is the most popular thickness for general shipping boxes. E Flutes Second in thinness, E flutes are approximately 1.6 millimeters or 1/16 inch thick. As many as 90 flutes fit within a single linear foot, resulting in a lightweight but strong structure. The thinness of E flutes makes them an excellent choice for reducing storage space and costs. Because of its thinness and excellent printing surface, E flutes are commonly used in packaging consumer goods, particularly those requiring a more sophisticated presentation, such as cosmetics and high-end electronics. F Flutes The thinnest of all, F flutes measure around 0.8 millimeters or 1/32 inch in thickness. About 128 flutes can be found within a single linear foot, making them ideal for creating stiff packaging for specific consumer goods. Due to their thinness and smooth printing surface, F flutes are often used in retail packaging for luxury goods and other high-end items. Going Beyond Flutes: Board Types, Box Styles, and Printing Methods Understanding the world of corrugated packaging goes beyond flutes. There are several other critical considerations, such as board type, box style, and printing type. Each of these factors plays a vital role in determining the best packaging solution for specific products and brands. Board Type Corrugated packaging materials consist of a combination of flutes and liners, and this combination can vary depending on the packaging’s intended use. Let’s look at the four primary types of corrugated board: Single-face: As the name suggests, a single-face board consists of one layer of fluting and one liner layer. Although it’s not as durable as other types, its cushioning properties make it ideal for additional inner packaging components. Single-wall: This is the most commonly used board type, comprising one layer of fluting sandwiched between two liners. It offers sufficient insulation and protection, making it a popular choice for shipping cartons. Double-wall: Essentially two boxes in one, a double-wall board has three liner layers surrounding two layers of fluting. This super-durable board type is excellent for packaging heavy industrial items. Triple-wall: The most durable board type available, a triple-wall board has four liner layers and three fluting layers. It’s like having three boxes in one, which makes it ideal for robust applications such as extremely heavy metal pieces, equipment and chemical