Stock Packaging

We supply businesses with a wide selection of essential packaging, shipping, and warehouse supplies. Get any standard packaging product by dimension or style from boxes, tubes, tapes, labels, and more. If you are unsure on what type of packaging you will need, then contact us for an expert consultation.

Stock packaging refers to pre-made, ready-to-ship packaging solutions like corrugated boxes, mailers, and protective materials that are designed to meet a wide range of standard needs across shipping, retail, and storage. Unlike custom packaging, stock options offer quick availability and reliable protection without the need for extensive design or production time, making them ideal for businesses needing efficient, high-quality solutions with fast lead times.

At Brown Packaging, we focus on providing durable, performance-driven stock packaging that supports our clients’ operational needs. Our stock products are sourced to ensure consistent quality and cost-effectiveness, offering a practical solution to keep operations running smoothly and on schedule. With an emphasis on reliability, we help our clients quickly access packaging solutions that meet their specific needs while maintaining quality across every order.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about custom packaging by reading our blog posts on new and trending topics.

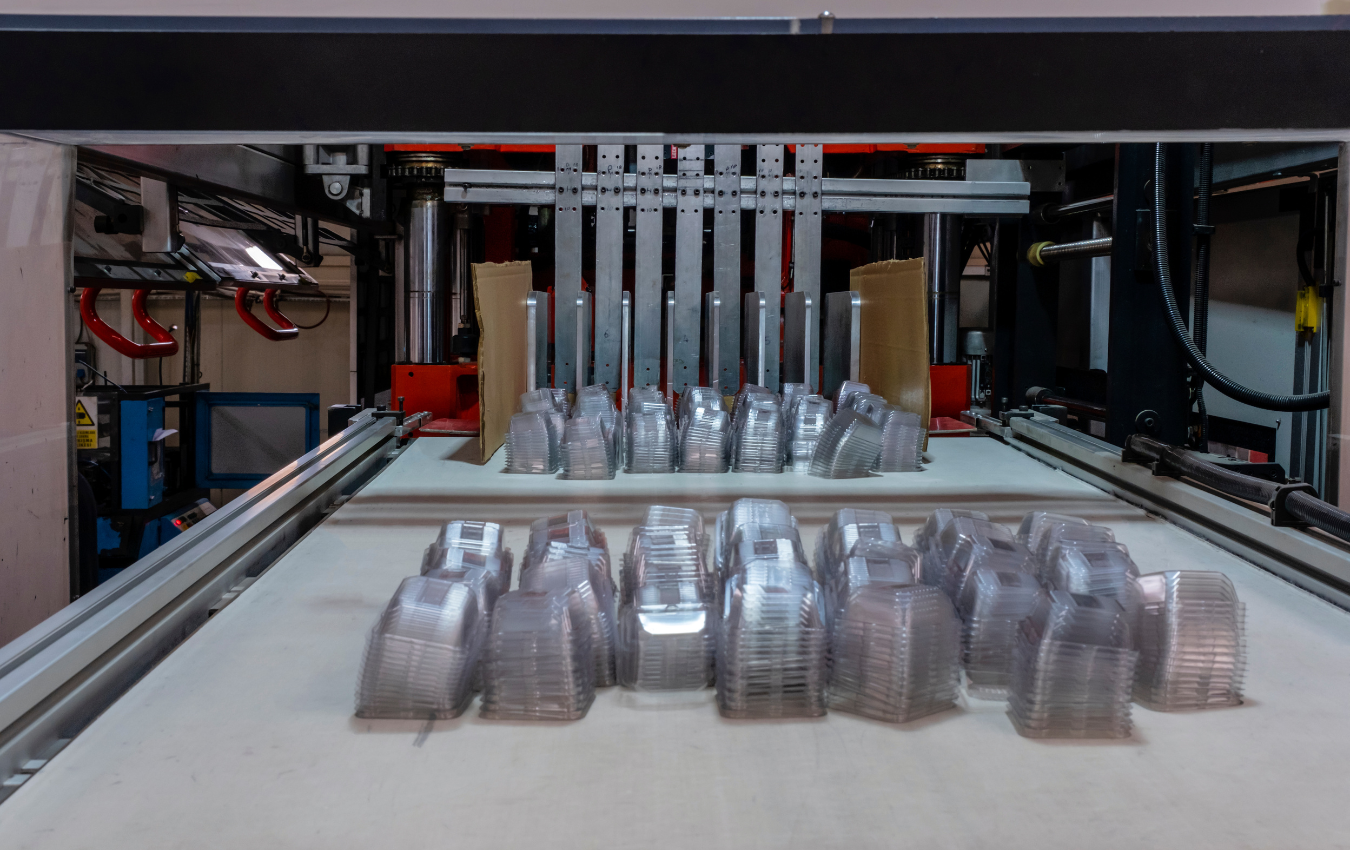

Thermoform packaging is the backbone of numerous sectors including food, pharmaceutical, electronics, cosmetics, and consumer goods, to name a few. Its high adaptability and customizability make it an unparalleled choice for businesses around the globe. This blog post seeks to dive deeper into the world of this unique process, exploring its labyrinthine facets. Thermoform Packaging: A Basic Overview Before we delve deeper, let’s first understand what thermoform packaging is. This process involves heating plastic sheets until they reach a pliable forming temperature. Once the material is pliable, it’s then formed into a specific shape using a mold. After the forming process, the plastic is trimmed and converted into finished packages. Common examples of thermoform packaging that you might encounter in your daily life include blister packs, clamshells, trays, and even innovative designs like trap packs. A Closer Look at the Types of Thermoform Packaging There are various types of thermoform packaging, each fulfilling a unique role in different industries. The most common types include blister packs, clamshells, trays, and the emerging trend of trap packs. Blister Packs: The Pharmaceutical Industry’s Favorite Blister packs are a ubiquitous sight in the pharmaceutical sector. They are most commonly used for packaging pills, capsules, or lozenges. A blister pack is made from a formable web, typically a thermoformed plastic, which is shaped into a cavity or pocket designed to securely hold the product. Clamshells: Versatile and Secure Clamshells, as the name suggests, are a type of packaging that resembles a clam in its structure. This form of packaging features two halves, which are connected through a hinge area. This design allows the packaging to open and close in a manner similar to a clamshell. Trays: A Jack of All Trades Trays represent another versatile form of thermoform packaging. These are extensively used to hold a plethora of items ranging from ready-to-eat meals in the food industry to various components in the electronics industry. Trap Packs: Innovative Consumer Goods Packaging Trap packs are an emerging trend in consumer goods packaging. They combine the advantages of thermoform packaging with innovative design elements, often featuring traps or compartments that enhance product organization and presentation. Trap packs are gaining popularity in industries where product visibility, organization, and aesthetics are crucial. The Detailed Thermoform Packaging Process Thermoforming packaging might seem straightforward, but it’s a complex process involving multiple stages. Each stage plays an integral role in crafting the final product. The Salient Advantages of Thermoform Packaging Thermoform packaging boasts numerous advantages. One of its most striking benefits is its high degree of customization. The process allows for virtually any shape to be achieved, making it apt for a wide variety of products, including the consumer goods sector. Another notable advantage of thermoform packaging is its cost-effectiveness. The materials utilized in this process are relatively inexpensive, and the production process is highly efficient. The packaging’s lightweight nature also contributes to a decrease in shipping costs. Transparency is yet another critical benefit. The clear nature of thermoform packaging allows potential consumers to view the product without needing to open the packaging. This quality makes thermoform packaging particularly appealing in the retail sector, especially for consumer goods where product visibility is a key selling point. Wrapping It Up Thermoform packaging is a multifaceted and versatile process that plays an indispensable role across a wide array of industries, including consumer goods. Understanding its intricate process and myriad benefits allows businesses to utilize this technology optimally, improving their product presentation, ensuring product safety, and boosting their profitability. As we continue to witness an evolution in the world of packaging, thermoform packaging stands firm as a reliable and efficient solution, adapting to the ever-changing demands of the consumer goods market. If you are interested in thermoform packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Thermoform Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Storage solutions are essential for any business who wants to organize their space efficiently. One of the most effective and economical options are corrugated bin boxes. These handy boxes can be an excellent way to declutter, systematize, and streamline storage areas. Let’s dive deep into what corrugated bin boxes are and how to maximize storage efficiency with them. What are Corrugated Bin Boxes? Corrugated bin boxes are storage boxes made from corrugated cardboard. They are durable, lightweight, and come in various sizes. Their unique design, which usually comprises a single sheet of cardboard folded and assembled in place, makes them especially suitable for stacking and organizing small items. Benefits of Using Corrugated Bin Boxes Cost-Effective: Compared to plastic or metal storage bins, corrugated bin boxes are much more affordable. This means you can buy more boxes for your budget, increasing your overall storage capacity. Eco-Friendly: Being made of cardboard, they are recyclable and biodegradable. This is a great way to reduce your carbon footprint while organizing your space. Customizable: You can easily label them, paint them, or even get them in custom sizes. Versatile: They can be used in various settings like warehouses, offices, homes, and retail stores. How to Maximize Your Storage Efficiency with Corrugated Bin Boxes Sort and Categorize: Before you start placing items into the boxes, sort and categorize everything. This step will help you determine the number and sizes of the boxes you need. Label Everything: Labeling each box with its contents will save you a lot of time and hassle. You can use permanent markers or printed labels. Consider using a color-coding system for even quicker identification. Optimal Box Size: Always choose the box size that closely fits the items you are storing. This reduces wasted space and ensures that items are snug and protected. Stack Smartly: Corrugated bin boxes are designed for stacking. However, ensure you stack heavier boxes at the bottom and lighter ones on top to prevent crushing and maintain stability. Regular Maintenance: Periodically go through your boxes to remove items that you no longer need. This will free up space and ensure that your storage remains efficient. Use Dividers: If you’re storing smaller items, consider using dividers within the boxes. This will keep items separate and more organized. Keep Accessibility in Mind: Store frequently used items towards the front and less frequently used items towards the back. Protect Against Moisture: While corrugated boxes are sturdy, they can be damaged by moisture. If you’re storing in a damp place, consider using pallets or shelving to keep them off the ground. Also, think about using silica gel packets inside the boxes to absorb any moisture. Reuse and Recycle: Instead of discarding boxes when you’re done with them, consider flattening them for reuse. If they’re no longer usable, ensure they’re recycled appropriately. Conclusion Corrugated bin boxes are a fantastic solution for those looking for affordable and efficient storage. With proper organization, labeling, and maintenance, these boxes can help you optimize your space, whether in a business setting or at home. Their eco-friendly nature, combined with their versatility, makes them an excellent choice for various storage needs. By following the above tips, you can make the most of these storage wonders and maintain an organized, clutter-free environment. If you are interested in corrugated bin boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce Design Foam Folding Carton Packaging Plastic Packaging Pouch Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Corrugated Bin Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

In the current competitive retail landscape, the packaging of a product plays an increasingly significant role in customer decision-making. Brands are progressively realizing the power of packaging as a communication tool. Among the many forms of packaging available, blister packs stand out as a popular choice for several reasons. They strike a balance between product visibility, protection, and cost-effectiveness, hence the growing demand across various industries. Defining Blister Packs: A Quick Overview Blister packs, also mistaken as clamshell packaging, are pre-formed plastic packaging solutions that seal the product against a cardboard backing or another plastic component. This type of packaging is widely used for small consumer goods, pharmaceuticals, and medical devices. Their design is purposefully transparent to showcase the product within, offering potential buyers a clear view of what they’re about to purchase. Increased Product Visibility: The Window to Purchase Decision Showcasing Product Quality One of the most significant advantages of blister packs is the transparency that allows customers to view the product directly. With the rise of informed consumers, the ‘see before you buy’ concept has never been more crucial. By providing an unobstructed view, blister packs instill confidence in the product, as consumers can verify the product’s condition and quality firsthand. Highlighting Product Features Through a blister pack’s clear plastic cover, brands have the opportunity to highlight the most critical product features. This visual promotion can be a game-changer, particularly for products with unique design elements or accessories that the company wants to emphasize. Deterring Product Tampering Product visibility also plays a vital role in preventing tampering. With blister packs, any signs of interference are easily recognizable, thus providing an additional layer of assurance to customers about the product’s integrity. Superior Product Protection: Ensuring Safety and Longevity Resistance to External Factors Blister packs provide superior protection against numerous external factors such as moisture, light, and temperature changes, making them suitable for products sensitive to such conditions, like pharmaceuticals and electronics. Enhancing Product Life Blister packs are designed to be tough and durable. The rigid plastic housing protects the product from mechanical damage during transport or in-store handling, thereby extending the product’s shelf life and ensuring it reaches the consumer in its best state. Improved Tamper Evident Packaging As previously mentioned, blister packs deter tampering. However, they also serve as excellent tamper-evident packaging. If the package is opened or damaged, it is immediately noticeable, allowing both the seller and the buyer to be assured of the product’s untouched condition. Balancing Cost-effectiveness and Environmental Concerns While the benefits of product visibility and protection are undeniable, it’s essential to highlight that blister packs are also cost-effective and can be designed with environmental concerns in mind. Economical Production and Versatility The production process for blister packs is relatively economical, making them an affordable option for many businesses. The versatility of blister packaging, fitting a wide range of products, also contributes to its cost-effectiveness. Eco-friendly Options In addition to traditional blister packs, some companies are now offering eco-friendly alternatives known as “trap packs.” Trap packs are designed with sustainability in mind, using recycled materials or materials that are easier to recycle. PET (Polyethylene Terephthalate) and RPET (Recycled Polyethylene Terephthalate) are commonly used due to their high recyclability. These eco-conscious trap packs provide the same level of visibility and protection while minimizing their environmental impact. Conclusion: The All-Round Packaging Solution Blister packs have proven their value in the world of product packaging. By boosting visibility and offering superior protection, these packs are instrumental in driving purchase decisions while ensuring products reach consumers in optimal condition. As eco-friendly options like trap packs become more widely available, blister packs are positioned to remain a popular choice for packaging needs in the foreseeable future. If you are interested in blister packs, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Blister Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts