Stock Packaging

We supply businesses with a wide selection of essential packaging, shipping, and warehouse supplies. Get any standard packaging product by dimension or style from boxes, tubes, tapes, labels, and more. If you are unsure on what type of packaging you will need, then contact us for an expert consultation.

Stock packaging refers to pre-made, ready-to-ship packaging solutions like corrugated boxes, mailers, and protective materials that are designed to meet a wide range of standard needs across shipping, retail, and storage. Unlike custom packaging, stock options offer quick availability and reliable protection without the need for extensive design or production time, making them ideal for businesses needing efficient, high-quality solutions with fast lead times.

At Brown Packaging, we focus on providing durable, performance-driven stock packaging that supports our clients’ operational needs. Our stock products are sourced to ensure consistent quality and cost-effectiveness, offering a practical solution to keep operations running smoothly and on schedule. With an emphasis on reliability, we help our clients quickly access packaging solutions that meet their specific needs while maintaining quality across every order.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about custom packaging by reading our blog posts on new and trending topics.

Packaging is more than just a means to protect and transport products. It is a powerful tool for brand recognition, customer engagement, and conveying product information. One of the foundational elements of effective packaging design is the packaging dieline. What is a Packaging Dieline? A packaging dieline is a two-dimensional blueprint or template that outlines the structure and dimensions of a product’s packaging. It serves as a guide for designers, manufacturers, and printers, ensuring that the packaging design aligns with the intended dimensions and specifications. Think of it as the architectural blueprint for your product’s packaging, offering precise measurements, cut lines, and folding instructions. Why is a Packaging Dieline Important? Accuracy: A packaging dieline ensures that the final product matches the intended design. It provides exact measurements and cut lines, reducing the risk of errors during production. Cost-Efficiency: By providing precise specifications, dielines help reduce material wastage and production costs. Efficient designs also enable easier assembly, saving time and labor costs. Consistency: Dielines establish a consistent design framework, making it easier to maintain brand identity across various products and packaging formats. Communication: It acts as a visual communication tool between designers, manufacturers, and printers, ensuring that everyone is on the same page regarding the packaging’s design and structure. What Should be Included in a Packaging Dieline? Product Dimensions: Start by specifying the dimensions of your packaging – length, width, and height. This information is critical for ensuring that the packaging fits the product snugly. Bleed and Trim Lines: Include bleed and trim lines to account for any design elements that extend beyond the final cut. Bleed ensures that the ink goes right to the edge of the printed material, while trim lines indicate where the packaging should be cut. Cut Lines and Perforations: Clearly mark where the packaging should be cut, folded, or perforated. This guides the manufacturer in the production process. Folding Instructions: If your packaging involves complex folds or assembly, provide clear folding instructions. This helps the assembly team understand how to put the packaging together correctly. Die Cut Indications: If your packaging requires die cutting (custom-shaped openings or designs), indicate these areas on the dieline. Die cut lines are essential for ensuring that the cutting process aligns with your design. Safety and Legal Information: Reserve space for essential legal and safety information, such as barcodes, nutritional labels, and warning labels. Ensure these elements are accurately placed within the dieline. Brand Elements: Include space for brand logos, taglines, and other brand-specific elements. Consistency in brand placement is crucial for brand recognition. Color Specifications: Specify color codes, ideally in Pantone or CMYK, to ensure color accuracy in printing. Include color swatches for reference. Font Styles and Sizes: Indicate the fonts, font sizes, and text placement within the dieline. This helps maintain consistency in typography. Finish and Coating Instructions: If your packaging requires specific finishes like gloss, matte, or special coatings, note these instructions on the dieline. Clear Zones: Designate areas where important information or design elements should not be placed to prevent interference with barcodes or legal text. Fold and Closure Types: If your packaging involves unique folding or closure mechanisms, provide detailed illustrations or descriptions to guide assembly. Conclusion A well-prepared packaging dieline is the cornerstone of a successful packaging design project. It ensures accuracy, cost-efficiency, and consistency throughout the production process. By including all the necessary elements, such as dimensions, cut lines, branding elements, and safety information, in your dieline, you pave the way for a visually appealing, functional, and on-brand packaging solution. Packaging dielines are the unsung heroes behind every attractive product on the retail shelf, and mastering their use is a crucial skill for any packaging designer. If you are interested in custom packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce Design Display Foam Folding Carton Packaging Plastic Packaging Printing Protection Retail Rigid Box Thermoform Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Corrugated boxes have been a staple in packaging and shipping for decades, and they continue to play a crucial role in various industries. As we look ahead to 2024, it’s essential to anticipate the top trends and innovations that will shape the corrugated box industry in the coming year. From sustainability and digitalization to customization and automation, this blog will explore the five key trends to expect in 2024 for corrugated boxes. Sustainability Takes Center Customization and Personalization Digitalization and Automation Improved Durability and Performance Smart Packaging Solutions Sustainability Takes Center Stage One of the most significant trends in the corrugated box industry in recent years has been a growing emphasis on sustainability. In 2024, this trend is expected to gain even more momentum. Consumers are increasingly conscious of environmental issues, and they demand eco-friendly packaging solutions. Corrugated boxes, being recyclable and biodegradable, align well with these consumer preferences. In 2024, we can expect to see: Increased use of recycled materials: Corrugated box manufacturers will likely source a higher percentage of recycled paper to reduce their environmental footprint. Eco-friendly printing inks: Printing on corrugated boxes will involve the use of environmentally friendly inks, reducing the use of harmful chemicals. Reduced packaging waste: Innovative designs and reduced material usage will contribute to less waste and more sustainable packaging solutions. Customization and Personalization In the age of e-commerce and online shopping, businesses are looking for ways to stand out from the competition. Corrugated boxes offer an excellent canvas for customization and personalization. In 2024, we can expect to see a surge in tailored packaging solutions: Branded packaging: Companies will invest in branded boxes that align with their brand identity, creating a memorable unboxing experience for customers. Variable data printing: Advanced printing technology will enable businesses to print unique information, such as customer names or personalized messages, on corrugated boxes. Custom shapes and sizes: Corrugated boxes will be designed to fit products perfectly, reducing excess packaging and improving aesthetics. Digitalization and Automation Digital technology and automation are revolutionizing the corrugated box industry. In 2024, we can anticipate: Digital printing advancements: Digital printing will continue to improve in terms of speed and quality, allowing for more intricate and colorful designs. Supply chain integration: Enhanced digital systems will enable better supply chain management and real-time tracking of corrugated box production and delivery. Automated packaging lines: Packaging companies will invest in automated production lines that streamline the manufacturing process, reduce labor costs, and increase efficiency. Improved Durability and Performance Corrugated boxes will become even more durable and capable of protecting products during transportation. Innovations in materials and designs will lead to: Enhanced strength-to-weight ratio: Corrugated boxes will be lighter yet stronger, reducing shipping costs and improving product protection. Advanced cushioning materials: Innovative cushioning materials will offer superior protection for fragile items. Water-resistant coatings: Corrugated boxes with water-resistant coatings will ensure that products remain undamaged even in adverse weather conditions. Smart Packaging Solutions In the ever-evolving world of packaging, 2024 will witness the rise of Smart Packaging Solutions, where technology meets corrugated boxes to enhance functionality and engagement. These innovative packaging solutions leverage digital advancements to provide real-time tracking, interactive experiences, and anti-counterfeiting measures, adding a new dimension to the corrugated box industry. Integration of smart technology: Corrugated boxes will incorporate technologies such as RFID tags, QR codes, or sensors to provide real-time tracking and monitoring of products during transit, enhancing supply chain visibility. Interactive packaging: Smart packaging will engage consumers with features like augmented reality (AR) experiences, providing additional information or entertainment when scanning the box with a mobile device. Anti-counterfeiting measures: Corrugated boxes may include security features to combat counterfeit products, ensuring product authenticity and consumer trust. This trend reflects the increasing adoption of technology and connectivity in packaging solutions to improve functionality and consumer engagement. Conclusion As we look ahead to 2024, the corrugated box industry is poised for significant developments. Sustainability, customization, digitalization, and improved performance will be at the forefront of these changes. Businesses that stay ahead of these five trends and embrace innovative solutions will not only reduce their environmental impact but also create memorable customer experiences and improve their bottom line. Corrugated boxes will continue to be a vital part of the packaging landscape, adapting to the evolving needs of businesses and consumers alike. If you are interested in corrugated packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

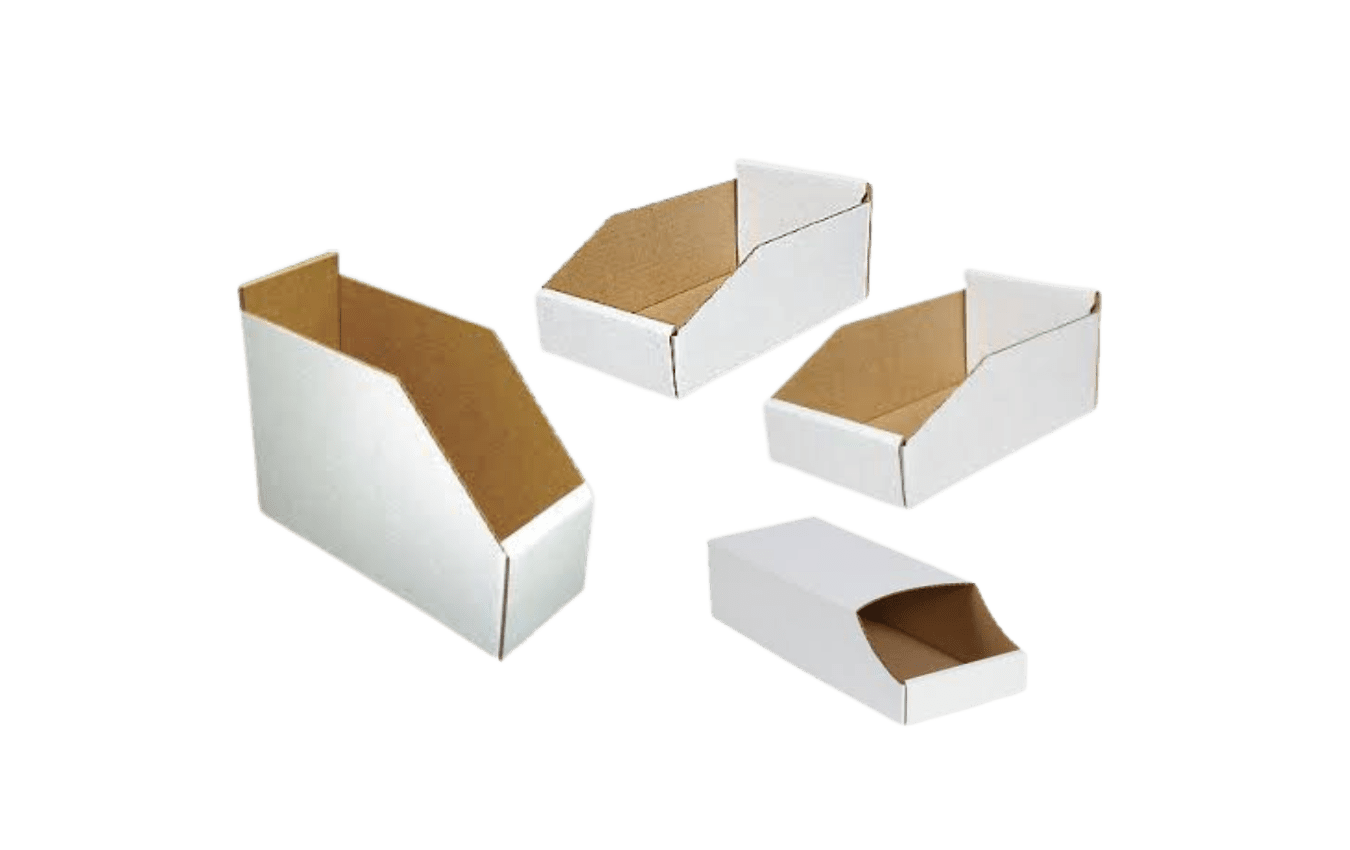

In the sprawling universe of storage solutions, corrugated bin boxes often go unnoticed. These unsung heroes of organization have a lot to offer when it comes to keeping products organized, safe, and easily accessible. Whether you’re running a business or just looking for ways to declutter your space, corrugated bin boxes might just be the answer to your organizational needs. What are Corrugated Bin Boxes? Before diving into their benefits, let’s understand what they are. Corrugated bin boxes, often made from corrugated fiberboard, are storage containers designed for storing, organizing, and categorizing small to medium-sized items. You might have seen them in workshops, warehouses, or even craft rooms. Benefits of Using Corrugated Bin Boxes Durability and Strength: Made from corrugated fiberboard, these boxes have a unique fluted structure that offers strength and resilience. They can hold heavy items without collapsing, and their durability ensures they last a long time. Customizable: These boxes come in various sizes and can be tailored to fit specific spaces or needs. Some suppliers even offer custom printing, so businesses can brand their storage solutions or add labels for better organization. Eco-friendly: Since they are primarily made from recycled materials, corrugated bin boxes are a green choice. And when they’ve reached the end of their lifespan, they’re 100% recyclable! Cost-effective: In comparison to plastic bins or metal storage systems, corrugated bin boxes tend to be more affordable. This makes them an ideal choice for businesses that need bulk storage solutions. Space-efficient: Their design allows for easy stacking, saving floor space. When labeled properly, products can be found and accessed quickly, increasing efficiency and productivity. Protection: Corrugated boxes provide a buffer against external forces. Their structure allows for some cushioning which can protect the contents from minor impacts. Applications and Uses Retailers: Corrugated bin boxes can keep backstock organized, making inventory management a breeze. Warehouses: These boxes are perfect for categorizing parts or products, making it easy for workers to locate and pick items. Craft rooms: Artists and crafters can store beads, buttons, threads, and other small items, keeping their workspace tidy and their materials easily accessible. Garages: These boxes can be used to organize tools, nuts, bolts, and other small parts, ensuring that everything has its place. Tips for Effective Use Labeling is Key: Always label your boxes. It helps in quick identification and retrieval of items. Consider using large, clear labels and possibly color-coding for different categories. Regularly Review Contents: Periodically check the contents of your boxes. Remove any items that are no longer needed, and make sure everything in the box belongs there. Keep Like Items Together: Group similar items or those that are used together. For instance, if you’re using boxes in a workshop, keep all screws in one box and nails in another. Consider Shelving: To maximize the benefits of these boxes, consider using shelving units. This elevates the boxes, making them easier to access and saving floor space. In conclusion, corrugated bin boxes are an exceptional organizational tool. Their versatility, durability, and cost-effectiveness make them a top choice for both businesses and individuals. The next time you find yourself drowning in clutter or struggling to streamline your inventory, consider the humble corrugated bin box. It might just be the organizational magic you’ve been searching for. If you are interested in corrugated bin boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce Design Foam Folding Carton Packaging Plastic Packaging Pouch Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Corrugated Bin Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts