Custom Appliance Packaging

Our appliance packaging solutions are engineered to protect products ranging from small countertop devices to full-size refrigerators. We offer custom corrugated boxes, foam inserts, edge protectors, and ESD-safe materials to ensure secure transit and compliance for sensitive or heavy-duty equipment. Whether you’re shipping blenders, microwaves, stoves, or refrigerators, we tailor every element to your product’s size, fragility, and logistics needs.

How Packaging Impacts Appliance Delivery & Customer Experience

For appliances, packaging isn’t just a protective shell—it’s a critical part of the product journey. Whether it’s a large refrigerator or a small countertop blender, the right packaging must account for weight, fragility, and handling logistics. A well-designed system minimizes risk during storage, palletization, and delivery, ensuring the appliance arrives undamaged and ready for use. This reduces returns, warranty claims, and downtime for your customers.

Just as important is the customer experience. In both ecommerce and retail, buyers expect packaging that reflects the product’s value. Clean presentation, minimal waste, and easy unpacking all play a role in how the appliance—and your brand—is perceived. Effective packaging not only protects but reinforces reliability, professionalism, and attention to detail.

Appliance Packaging Options

Selecting the right packaging for your appliance is critical to ensuring product integrity, brand presentation, and safe delivery. From material strength to internal protection and shipment method, every detail should align with your product’s size, fragility, and route to market.

Corrugated boxes are the backbone of appliance packaging, trusted across industrial and ecommerce channels for their strength and versatility. Whether you're shipping a refrigerator or a countertop microwave, double-wall or triple-wall corrugated structures deliver serious durability without unnecessary weight. These boxes protect against crushing, shifting, and punctures in transit—critical for reducing returns and damaged deliveries. Custom sizing, printing, and load-bearing options make them ideal for everything from bulk shipping to branded unboxing.

Folding cartons are perfect for smaller appliances and accessories—like blenders, irons, or electric kettles—where presentation matters just as much as protection. Lightweight, compact, and cost-effective, they help your product stand out in retail and ecommerce with crisp graphics and structural precision. They’re also easy to assemble and customize, offering a scalable option for fast-moving consumer appliances or bundled items. Ideal for brands balancing performance with visual impact.

When appliances need to arrive in flawless condition, foam is the go-to protective solution. Custom PE, EPE, or PU foam inserts absorb shocks, prevent movement, and cradle fragile surfaces—making them essential for everything from induction cooktops to high-end espresso machines. Foam fills in the protection gaps where corrugated alone isn't enough, especially for items with glass, metal, or complex wiring. It’s not just protection—it’s peace of mind in transit.

Edge protectors safeguard the most vulnerable part of your packaging—corners and edges where impact damage is most likely. They’re critical when shipping large, heavy appliances like stoves or dishwashers, especially in palletized or stacked formats. By reinforcing box integrity and absorbing compression, they help reduce claims and boost customer satisfaction. If you’re shipping bulk or dealing with high freight volumes, this is the cost-effective barrier your products need.

Poly bags are a versatile and lightweight packaging solution ideal for cords, manuals, hardware, or accessory components that ship with appliances. They keep contents clean, organized, and protected from dust, moisture, and abrasion. Great for both internal packaging and final presentation, poly bags enhance both shipping efficiency and customer experience. Whether it's a power cord or a parts kit, they help you deliver a clean, complete product.

Stretch film provides a tight, secure wrap around appliances during palletization or transit, preventing movement and exposure to dust, moisture, and abrasion. It’s especially useful for securing irregularly shaped or stacked loads while keeping branding visible and barcodes scannable. Whether you're shipping boxed microwaves or shrink-wrapped washer-dryer sets, stretch film is a must-have for clean, controlled containment.

For appliances with sensitive electronics—like smart ovens, induction ranges, or built-in digital interfaces—ESD bags and foam offer vital electrostatic protection. They prevent damage from static discharge during shipping and handling, especially in dry or high-friction environments. This packaging is essential for preserving function and ensuring full performance upon arrival.

Protective films and appliance covers shield finished surfaces from scratches, scuffs, and handling damage throughout the supply chain. Commonly used for glass panels, polished metal, and touchscreens, they preserve visual quality until the moment of installation. Peel-away films also enhance the customer’s unboxing experience by revealing a pristine, untouched product.

Custom inserts—made from corrugated, foam, or molded materials—stabilize appliances inside outer packaging to eliminate internal movement. They protect delicate components like control panels, knobs, and display screens from impact or pressure. Inserts are especially valuable for multi-part products or accessories, keeping everything organized and intact from warehouse to end user.

Looking for something specific to your product line or supply chain? Contact Brown Packaging to explore custom solutions tailored to your performance, compliance, and branding requirements. Whether it's engineered cushioning, thermal protection, or unique form factors, we’ll help you get it right.

Appliance Packaging Applications & Solutions

Our appliance packaging solutions are built to meet the demands of industrial, ecommerce, and retail buyers, offering reliable protection, streamlined handling, and strong brand presentation. From custom-fit corrugated boxes and foam inserts to edge protection and retail-ready cartons, we help ensure every appliance—large or small—arrives intact and ready for sale.

Refrigerators and freezers demand heavy-duty corrugated boxes, custom foam inserts, and edge protectors to withstand the rigors of freight and last-mile delivery. These high-value units are bulky, fragile, and frequently shipped upright, so structural stability and shock absorption are critical. For manufacturers and distributors, durable packaging reduces transit damage and returns—protecting both product and brand reputation.

Large kitchen appliances like stoves and ovens require reinforced corrugated packaging, corner guards, and optional protective films to shield delicate surfaces from scratches and dents. Heat-resistant finishes and glass elements need extra care in transit. Engineered packaging ensures safe transport, efficient warehousing, and proper orientation handling for these high-weight appliances.

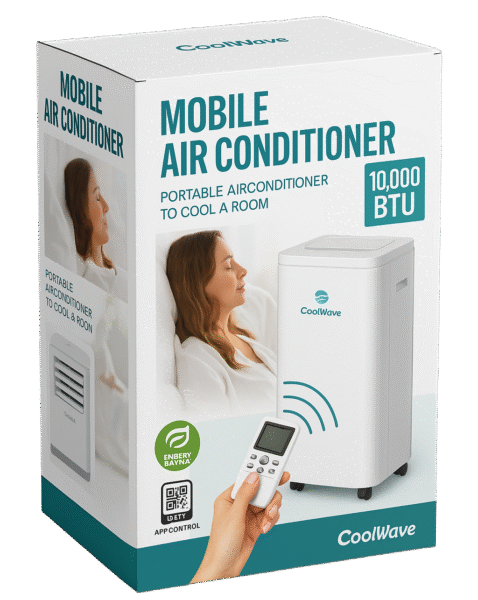

With varying unit sizes, air conditioners and heaters benefit from custom foam blocking, poly bag covers, and multi-panel corrugated containers. These products often include coils, vents, and digital panels that need targeted protection. Proper packaging also helps maintain airflow for storage and avoids cosmetic or functional damage during distribution.

Microwaves are compact but include sensitive components like digital interfaces and rotating plates. Die-cut inserts, folding cartons, and shock-absorbing foam provide compact, secure packaging that maximizes pallet density while minimizing movement. Whether sold in-store or online, secure packaging ensures it arrives shelf-ready or customer-ready with no cosmetic flaws.

Blenders are often shipped in folding cartons with molded inserts to protect glass jars, motors, and blades. These items benefit from poly bags to contain accessories and foam padding to prevent internal damage. Packaging needs to balance aesthetics for retail with durability for e-commerce shipments.

Toasters are typically packed using folding cartons with lightweight foam or corrugated inserts. Their metal exteriors are vulnerable to dings, so snug internal fit and scuff-resistant packaging is important. Packaging must also accommodate multiple plug types or accessories depending on the distribution region.

Water heaters are tall, heavy, and vulnerable to tipping or base damage, requiring vertical corrugated shippers, bottom cushions, and strap-compatible wraps. Foam collars and reinforced skids are often used to distribute weight evenly. This packaging ensures safe handling from warehouse to job site.

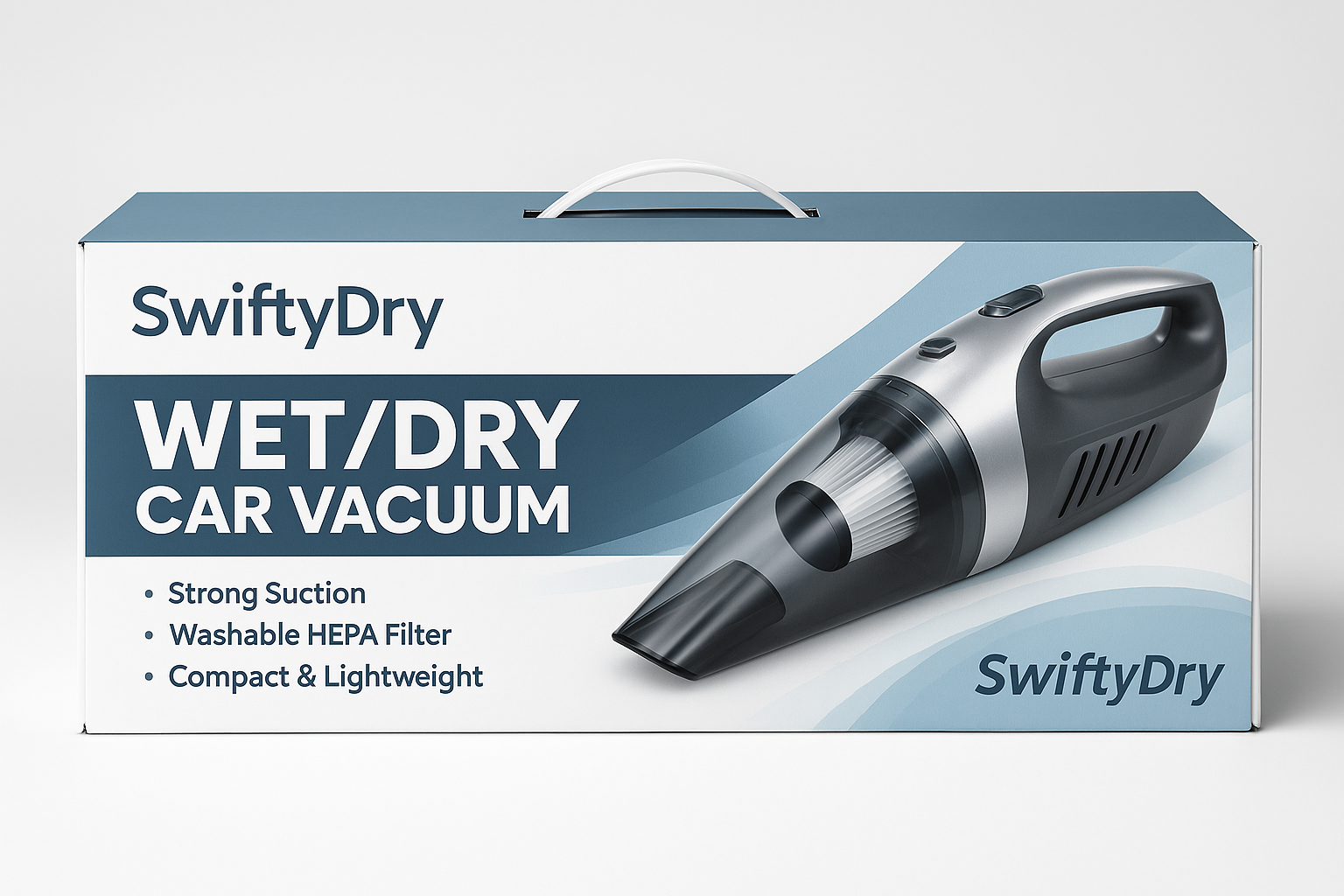

Vacuum packaging must secure motors, handles, and attachments using multi-component inserts, folding cartons, and internal dividers. Whether upright, canister, or handheld, proper packaging ensures compact layout and protection for delicate electronics. Especially in e-commerce, clean presentation and durability are equally important.

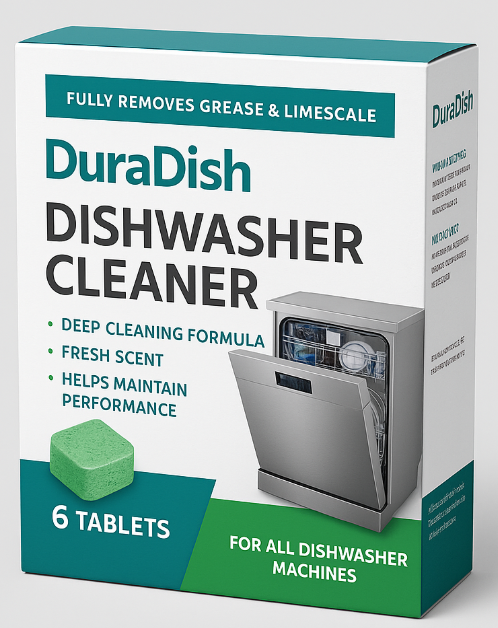

Appliance accessories and cleaning products require protective yet compact packaging that accommodates varied shapes and materials. From inserts for small attachments to poly bags and folding cartons for liquids, pads, or filters, the right packaging keeps items organized and spill-free. Whether bundled with the appliance or sold separately, well-designed packaging ensures a clean, secure presentation across retail and ecommerce channels.

Dishwashers require reinforced corrugated packaging, edge protection, and foam bracing to protect their internal racks, pumps, and stainless-steel panels during transit. With multiple moving components and a high moisture sensitivity, they benefit from secure, fitted packaging that maintains stability. For industrial and e-commerce delivery, this ensures units arrive clean, intact, and customer-ready.

Due to their size and weight, washers and dryers are shipped in double-wall corrugated boxes with corner foam, stretch film, and shock-absorbing inserts. These appliances often face long hauls and warehouse stacking—packaging must prevent shifting and absorb vertical and lateral impacts. Proper packaging minimizes costly handling damage and aligns with freight standards.

From compact brewers to commercial espresso units, coffee machines require folding cartons, foam inserts, and poly bag wrapping to protect delicate components like carafes, valves, and electronics. Precise packaging ensures a strong brand presence in retail and an intact product for direct-to-consumer shipments. For e-commerce, unboxing experience is key.

Edge protectors safeguard the most vulnerable part of your packaging—corners and edges where impact damage is most likely. They’re critical when shipping large, heavy appliances like stoves or dishwashers, especially in palletized or stacked formats. By reinforcing box integrity and absorbing compression, they help reduce claims and boost customer satisfaction. If you’re shipping bulk or dealing with high freight volumes, this is the cost-effective barrier your products need.

Range hoods include sharp edges, electrical parts, and often delicate filters, which need custom corrugated boxes, corner padding, and internal dividers. These components are lightweight but damage-prone, so packaging must keep parts organized and cushioned. Well-structured packaging simplifies installation and reduces returns.

Ice makers—whether freestanding or under-counter—contain electrical components, stainless exteriors, and water hookups. These need protective film, foam cradles, and compact corrugated packaging with inserts to hold accessories in place. Effective packaging prevents moisture exposure and ensures damage-free delivery.

Electric griddles and countertop cookware often feature nonstick surfaces, control knobs, and plug-in components that require careful protection. Packaging typically includes custom foam inserts, folding cartons, and poly bags to prevent surface abrasion and damage to electrical connections. Whether sold in bulk or direct-to-consumer, secure and presentable packaging ensures the product arrives ready for use and display.

If your appliance product doesn’t fall within these categories or has unique handling needs, contact Brown Packaging for fully customized solutions that meet your protection, compliance, and brand requirements.

Appliances—especially large or high-value units—require packaging that can withstand vibration, impact, and pressure throughout transit. We offer heavy-duty corrugated boxes, foam blocking, edge protectors, and more to ensure structural integrity from warehouse to installation site. Protective packaging prevents costly damage, returns, and warranty claims while maintaining the product's finish and functionality.

Appliance packaging should streamline every step of the logistics chain. We offer stackable designs, pallet optimization, and SKU-specific configurations to reduce storage footprint and simplify fulfillment. Improved handling efficiency and reduced material waste lead to real savings across distribution, warehousing, and delivery.

For appliances sold in retail settings, packaging must deliver both presentation and protection. We provide custom-printed boxes, UPC labeling, and clear assembly instructions to improve shelf appeal and consumer confidence. Whether it's a countertop blender or compact microwave, retail-ready solutions enhance visibility and simplify stocking.

Packaging for direct-to-consumer shipments must perform under tough conditions. We design compact, secure packaging that resists drops, moisture, and rough handling, while still being lightweight to minimize shipping costs. Internal inserts and foam cradling ensure that even smaller appliances arrive intact and branded for the unboxing experience.

We offer eco-conscious packaging alternatives to meet growing customer and regulatory demands. From recyclable corrugated to reusable inserts and low-impact coatings, our solutions balance sustainability with protection. Environmentally friendly choices don’t mean compromise—they mean added value to both brand and buyer.

Appliance packaging is not one-size-fits-all. We provide access to a full range of materials including single-wall, double-wall, and triple-wall corrugated, as well as PE and PU foams, plastic films, and recyclable fill. Whether the goal is cost reduction, premium branding, or maximum durability, we match the material to your performance needs.

Appliance packaging must often withstand climate-controlled storage and last-mile delivery challenges. We offer coated corrugated, moisture-barrier films, and sealed poly bagging for appliances vulnerable to rust, swelling, or mold. These upgrades protect your investment when standard cardboard isn’t enough.

A key factor in preventing appliance damage is ensuring a tailored fit. We design precision inserts, foam cradles, and tight structural cavities to eliminate shifting and absorb shock. Proper cushioning is especially critical for sensitive electronics, glass components, and custom hardware.

Heavy appliances demand structural packaging capable of safe stacking during transit and storage. We provide reinforced corners, crush-resistant designs, and palletization support to maintain load integrity and reduce damage from collapse or shifting. The result: safer shipping and fewer losses.

Appliance customers want packaging that’s intuitive and frustration-free. We include tear strips, easy-open tabs, printed guides, and even color-coded components to speed up unboxing and installation. That final touchpoint improves user satisfaction and reduces service calls.

Have a unique challenge or specialized requirement? Contact Brown Packaging to explore custom appliance packaging solutions tailored to your product’s size, weight, materials, and market. We’re here to help you meet performance, compliance, and cost-efficiency goals with confidence.

Packaging Services For Your Appliance

Our appliance packaging services are built to deliver precision, protection, and performance at every stage—from concept to shipment. With tailored support in design, print, testing, and prototyping, we help ensure your packaging works exactly as needed for appliances of any size or category.

Our structural design services ensure your appliance packaging is engineered for real-world demands. Whether it’s a refrigerator, microwave, or blender, we develop tailored box styles, inserts, and protection elements for maximum performance. Designs account for weight distribution, stackability, and transit handling. Every solution is built to reduce damage, optimize space, and improve product delivery.

We help you deliver a better brand experience through clear, professional packaging design. Our team can lay out warning icons, handling instructions, and product visuals to enhance both functionality and visual appeal. Whether you’re in industrial B2B or ecommerce, clean graphics support compliance, customer expectations, and presentation. You get packaging that looks sharp and works hard.

We help you deliver a better brand experience through clear, professional packaging design. Our team can lay out warning icons, handling instructions, and product visuals to enhance both functionality and visual appeal. Whether you’re in industrial B2B or ecommerce, clean graphics support compliance, customer expectations, and presentation. You get packaging that looks sharp and works hard.

Before we run full production, we offer custom prototypes and pre-production samples for review and testing. This lets you validate structure, branding, and product fit—so there are no surprises when it ships. It’s ideal for new appliance lines, product launches, or packaging updates. You get peace of mind and precision before committing to volume.

We conduct in-house material testing to ensure strength, protection, and compliance standards are met. Packaging is evaluated for burst strength, impact resistance, and stack compression, depending on the appliance’s size and risk factors. This service helps prevent transit damage and improves downstream reliability. You know your packaging will perform before it ever leaves your dock.