Custom Roll End Tuck Top With Dust Flap and Cherry Lock (RETTDFCL) Corrugated Boxes

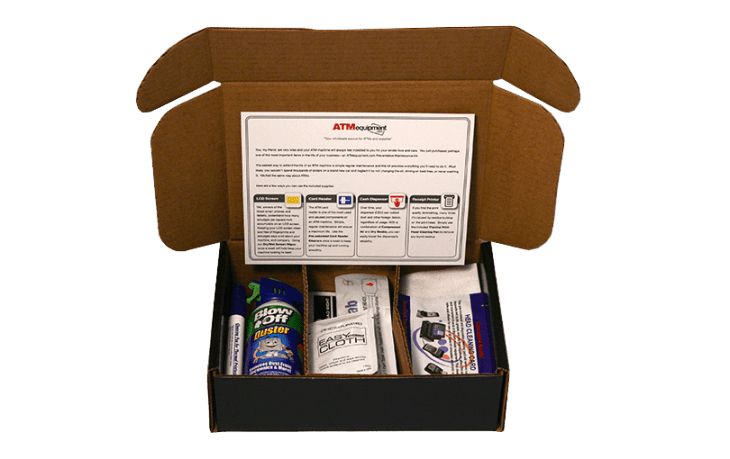

Our Roll End Tuck Top Dust Flap & Cherry Lock (RETTDFCL) corrugated boxes offer secure, sturdy packaging solutions with customizable structural and graphic designs. Ideal for a wide variety of applications, these boxes provide enhanced protection during transit while showcasing your brand with precision-printed visuals. Whether you need custom sizing, unique designs, or eye-catching graphics, our RETTDFCL boxes are tailored to meet your packaging needs.

What is A RETTDFCL Corrugated Box?

The Roll End Tuck Top Dust Flap & Cherry Lock (RETTDFCL) box is a reliable and versatile packaging solution, commonly used in e-commerce, retail, and shipping industries. Designed to safeguard products, it is especially effective for transporting fragile or high-value items that require extra care during transit. These boxes are lightweight yet durable, offering excellent protection against potential damage while maintaining ease of use for both packaging and unpacking. They are also ideal for stacking and storage, making them a practical choice for businesses handling large inventories or frequent shipments.

Customization is a key feature of RETTDFCL boxes, allowing businesses to tailor their packaging to fit specific needs. They can be customized with unique dimensions, printed branding, and vibrant designs to enhance product presentation and strengthen brand identity. Whether used for direct-to-consumer shipments or in retail settings, these boxes provide a professional and polished look, ensuring that your products stand out while arriving safely and in perfect condition.

Structural Design of RETTDFCL

The Roll End Tuck Top Dust Flap & Cherry Lock (RETTDFCL) box is a corrugated packaging style designed for secure closure without the need for additional adhesives. It features a roll-end structure with a tuck-top design, dust flaps for added protection, and a cherry lock mechanism to keep the lid firmly in place. This combination ensures a sturdy, reusable box that protects its contents from dust, dirt, and damage during handling and shipping.

Dust Flap

A dust flap is a structural feature in certain packaging designs, such as corrugated boxes, that adds an extra layer of protection to the contents. Positioned along the edges of the box's lid or opening, dust flaps fold inward to seal gaps and prevent dust, dirt, and debris from entering the package. Commonly used in shipping and storage, dust flaps help maintain product cleanliness and integrity, especially for items that require a pristine presentation or are sensitive to environmental contaminants.

Cherry Lock

A cherry lock is a secure locking mechanism commonly used in corrugated box designs to keep the lid firmly in place. It involves interlocking tabs that fit into corresponding slots, creating a sturdy closure without the need for adhesives or tape. This feature not only enhances the box's durability during transit but also provides easy assembly and reopening, making it a practical choice for reusable or high-frequency packaging applications.

How To Measure a RETTDFCL

Important Note:

The dimensions provided on the dieline are usually in flat format (unassembled). Always consider the material thickness for final internal and external dimensions of the box.

To measure a Roll End Tuck Top Dust Flap and Cherry Lock (RETTDFCL) box using a dieline, follow these steps:

Step 1: Identify the Key Dimensions

The key dimensions of a box are the length (L), width (W), and depth (D). These measurements are typically taken for the internal space of the assembled box:

- Length (L): The longer side of the base.

- Width (W): The shorter side of the base.

- Depth (D): The height of the box from the base to the top edge.

Step 2: Locate the Measurements on the Dieline

Using the dieline, you can calculate these dimensions:

- Measure the main rectangular section in the center of the dieline. This represents the length and width of the box.

- In this dieline, the marked dimensions are as follows: 13 1/4″ is the length, 7 13/16″ is the width, and 2 13/16″ is the depth.

- Measure the side flaps (perpendicular to the base) to confirm the depth if not marked.

Step 3: Add Dust Flap & Cherry Lock Considerations

The dieline includes extra sections for:

- Dust flaps: Measure these smaller panels separately; they are typically extensions of the side walls.

- Cherry locks: These are the tabs designed to snap into place for secure closure. Include their length and placement as part of the overall design.

Step 4: Confirm Total Box Size

- Use the dimensions of the center panel and add the appropriate extensions for all flaps (top, bottom, and sides).

- If unsure, confirm by folding the dieline into its box shape to cross-check measurements.Step 2: Locate the Measurements on the Dieline

Using the dieline, you can calculate these dimensions:

- Measure the main rectangular section in the center of the dieline. This represents the length and width of the box.

- In this dieline, the marked dimensions are as follows: 13 1/4″ is the length, 7 13/16″ is the width, and 2 13/16″ is the depth.

- Measure the side flaps (perpendicular to the base) to confirm the depth if not marked.

RETTDFCL Graphic Design & Printing

Our graphic design services for RETTDFCL boxes ensure your brand stands out with vibrant, high-quality visuals tailored to your specifications. From logos to full-scale artwork, we create engaging designs that enhance the box’s functionality and presentation for retail or shipping purposes.

Digital printing uses electronic files to print images directly onto packaging materials without the need for traditional printing plates. This method is ideal for short runs and custom designs, offering flexibility, quick turnaround times, and cost efficiency for smaller orders. Digital printing excels in producing high-quality, vibrant images, making it perfect for personalized packaging or designs with frequent changes. However, it may not be as cost-effective for large production runs, and its color matching capabilities can be limited compared to other methods.

Flexographic printing, or “flexo,” uses flexible rubber or polymer plates to transfer ink onto various materials, including plastic, paper, and corrugated substrates. It is well-suited for high-volume production and works effectively on uneven surfaces, such as flexible packaging and labels. Flexo offers fast production speeds and is versatile with a wide range of substrates and inks, including water-based options. Its main drawbacks include higher upfront costs for plate creation and less precision in fine detail compared to digital or lithographic printing, making it better suited for simpler designs.

Lithographic printing, also known as offset printing, involves transferring an inked image from a plate to a rubber blanket, which is then pressed onto the final material. This method delivers superior print quality, with sharp details and vibrant colors, making it ideal for high-end packaging like folding cartons or rigid boxes. It is highly efficient for large production runs. Lithographic printing is not as flexible as digital printing for smaller runs or frequent design changes, but its precision and consistency make it a preferred choice for premium packaging.