Custom Corrugated Boxes

Our custom corrugated boxes are designed to meet your specific packaging needs, offering durability and practicality. These boxes not only protect your products during storage and shipping but also serve as effective displays on retail shelves, enhancing product visibility. Suitable for various industries and product types, they ensure safe and secure delivery while making your items stand out in stores.

What Is A Corrugated Box?

Corrugated boxes, also referred to as cardboard boxes, are made up of multilayer fiberboard that consists of a top liner, flute in the middle, and an inner liner. This material is designed to be sturdy and highly durable. Corrugated boxes are used every day by all industries for shipping and product display purposes. Often, many people mistake corrugated material for cardboard, which is not the proper term.

Corrugated boxes can be manufactured using either a machine-run process or a die-cutting process, depending on the specific design and requirements of the box.

In general, machine-run boxes are produced by feeding a continuous roll of corrugated board through a machine that cuts, scores, folds, and glues the material into the desired box shape. This process is often used for standard, simple box designs with straight edges and minimal customization. Examples are RSC, HSC, FOL, and Gaylord boxes.

On the other hand, die-cutting is a process in which a custom-made metal die is used to cut and crease corrugated board into a specific shape or design. This process is ideal for creating complex box designs, such as those with handles, windows, or unique shapes. Die-cutting can be performed using flat or rotary tooling, depending on the complexity and production requirements. Examples are tuck-end, roll-end tuck-top, folders, trays, bin boxes, and others.

Custom Corrugated Box Style Options

Corrugated boxes, often referred as cardboard boxes, are extremely versatile in use, as a result they are one of the most common used packaging product worldwide. Here are some of the most popular corrugated packaging applications we can help you with, but are not limited to:

Custom Corrugated Box Applications & Solutions

Selecting the right custom corrugated box style is crucial for optimizing your packaging solution. Our range includes options like RSC (Regular Slotted Container), RETT (Roll End Tuck Top), FOL (Full Overlap), and more, each designed to suit specific packaging needs. Choosing the appropriate style ensures that your products are not only well-protected during storage and transportation but also efficiently presented, contributing to a seamless packaging experience for both businesses and customers.

Retail businesses rely on versatile packaging solutions to efficiently package and display a wide range of products, ensuring safe storage and attractive presentation for items like clothing, electronics, and home goods. See more retail packaging solutions.

In the world of e-commerce, effective packaging is essential for shipping and delivery. Packaging solutions come in various sizes to accommodate products of different shapes and sizes, ensuring safe and cost-effective shipping to customers. Learn more about our ecommerce packaging solutions.

Food companies rely on dependable packaging solutions to store and transport their products, including fresh produce and canned goods. These solutions adhere to strict food safety standards, preserving product integrity and freshness. Checkout our food packaging solutions.

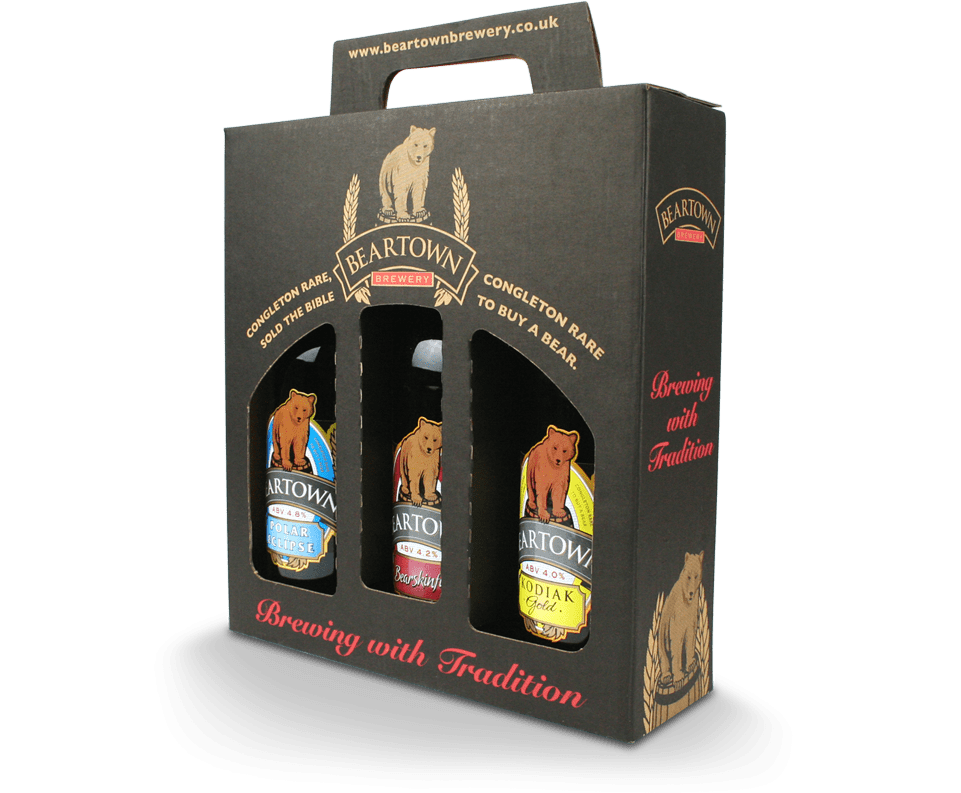

Beverage manufacturers require reliable packaging solutions to store and transport their products, ensuring the safe delivery of beverages while maintaining their quality and appeal. View our beverage packaging solutions.

Industrial applications require sturdy and dependable packaging solutions for storing and transporting heavy machinery parts, tools, and industrial equipment, providing protection against wear and tear. Visit our industrial packaging page.

The electronics industry relies on protective packaging solutions to safeguard delicate electronic components and devices during shipping and storage, minimizing the risk of damage. Learn more about our electronic packaging page.

Toy manufacturers and retailers prioritize packaging solutions that enhance product visibility on store shelves while ensuring toys remain safe and well-presented to potential customers. Learn more about our toy packaging solutions.

The pet industry relies on packaging solutions to provide pet owners with easy access to pet food, toys, and accessories. These solutions maintain the quality and accessibility of pet products. Learn more about our pet packaging products and services.

Cosmetics and personal care products require visually appealing yet protective packaging to ensure safe delivery and strong brand recognition. Custom corrugated boxes can be designed with high-quality printing, inserts, and eco-friendly materials to enhance the unboxing experience. Sturdy construction prevents damage to fragile glass bottles, skincare jars, and makeup products, ensuring they arrive in pristine condition. With customizable sizes, finishes, and coatings, these boxes provide both aesthetic appeal and functional protection.

Aerospace and defense components require extreme protection against impacts, vibrations, and environmental conditions. Custom corrugated boxes with multi-layered protection, anti-static materials, and foam inserts ensure that sensitive equipment remains secure. These boxes are engineered to meet strict industry regulations, providing shock resistance and moisture control for delicate parts. With customized sizing and reinforced structures, they deliver maximum protection for high-value aerospace and defense applications.

Bikes and cycling accessories demand durable, well-structured corrugated boxes to prevent damage during shipping and handling. Custom packaging solutions include double-wall corrugated boxes, protective inserts, and reinforced corners to secure frames, wheels, and accessories. These boxes are designed for ease of assembly, secure closures, and sustainable materials, ensuring safe and eco-friendly packaging. Custom branding and printing enhance brand visibility for direct-to-consumer shipments or retail displays.

Snack packaging requires sturdy, food-safe corrugated boxes that maintain freshness and prevent crushing. Whether for chips, granola bars, or gourmet treats, these boxes offer custom partitions, moisture resistance, and tamper-proof designs to keep products intact. Customizable printing and die-cut windows can enhance branding and consumer appeal for retail displays. Corrugated snack packaging is also optimized for bulk distribution, direct-to-consumer shipments, and sustainable packaging solutions.

Contact Brown Packaging: Custom corrugated boxes serve a wide range of industries, providing durability, protection, and branding for countless applications. From luxury goods and subscription boxes to industrial equipment and electronics, we offer tailored packaging solutions designed to meet your product’s specific needs. Whether you require impact-resistant shipping boxes, eco-friendly alternatives, or retail-ready displays, our team ensures your packaging is both functional and visually appealing. Contact Brown Packaging today to discuss your packaging needs and let us help you create the perfect solution for your business.

Single-print packaging solutions offer cost-effective customization with a single design on the exterior. Ideal for businesses looking to optimize branding while maintaining a consistent look across various products and industries.

Multi-print packaging allows for diverse and eye-catching designs on different panels of the packaging. This versatile solution caters to industries where visual impact and product differentiation are crucial, such as retail, cosmetics, and electronics.

Custom packaging designed specifically for product display helps businesses create enticing in-store presentations. These solutions enhance product visibility and are often used in retail environments to attract and engage customers effectively.

Shipping boxes are engineered for secure and efficient transportation of products. Sturdy and durable, they provide protection during the shipping process and are commonly used in e-commerce, manufacturing, and distribution industries.

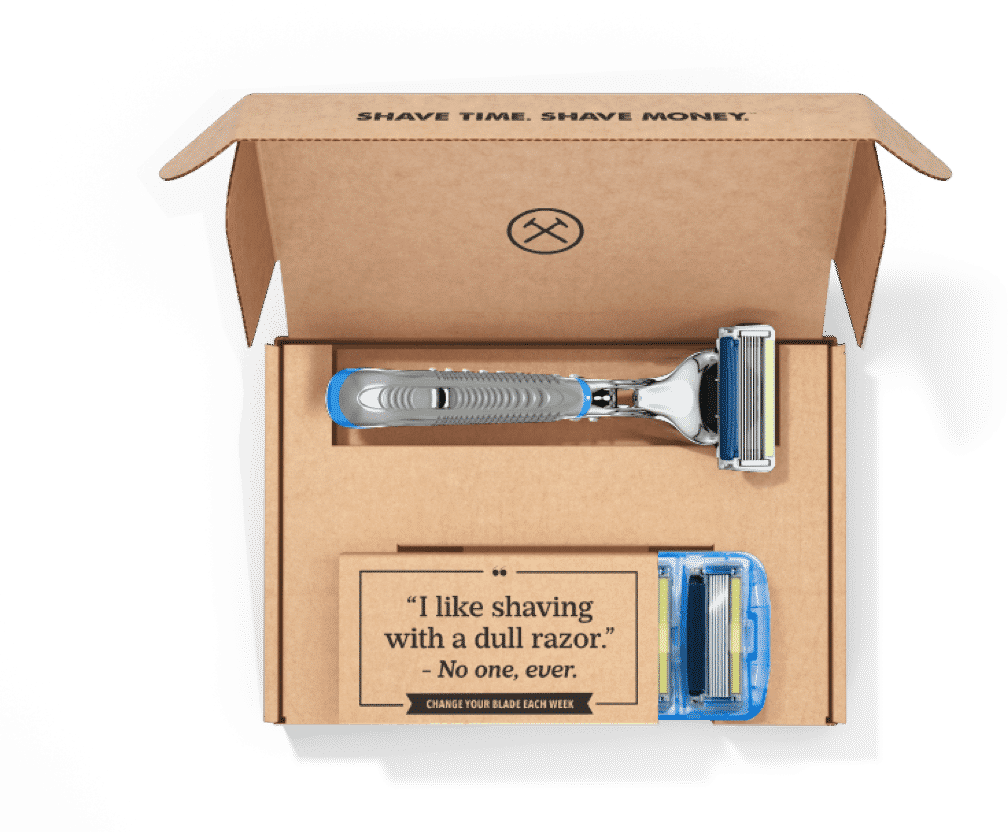

Subscription boxes offer a delightful unboxing experience for customers receiving regular shipments. These customized solutions cater to various subscription services, from cosmetics and snacks to books and lifestyle products. Learn more about our subscription boxes.

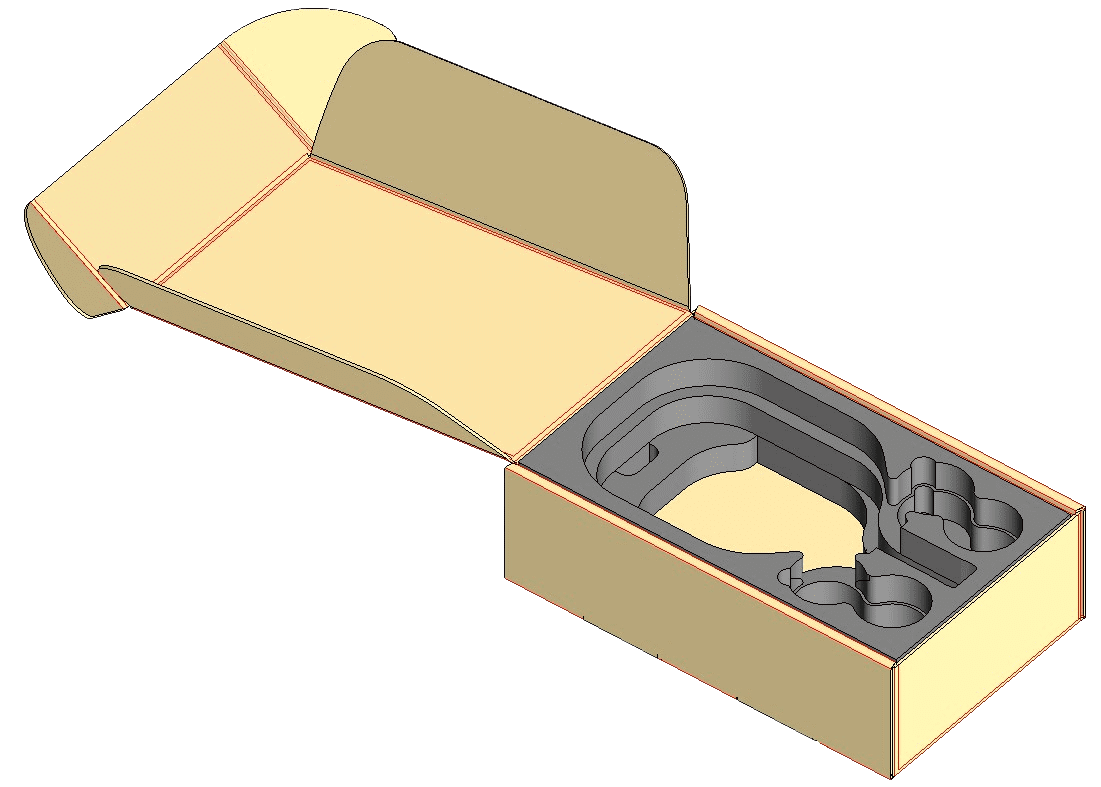

Custom inserts provide precision-fit protection for fragile, irregularly shaped, or high-value products, ensuring they stay secure during transit. Whether made from corrugated board, foam, or molded pulp, inserts prevent movement and minimize damage caused by impacts or vibrations. They are ideal for industries like electronics, auto parts, cosmetics, and food, where maintaining product integrity is essential. Inserts can also enhance the unboxing experience, making products easier to access while reinforcing brand presentation.

Tamper-evident packaging features security seals, locking mechanisms, and breakaway closures to protect against unauthorized access. Industries such as pharmaceuticals, electronics, and food rely on these solutions to ensure product authenticity and consumer safety. Custom tamper-evident designs help deter theft, prevent contamination, and reinforce customer trust. By integrating RFID tracking, perforated seals, and reinforced adhesives, businesses can safeguard their products while complying with industry regulations.

Sensitive electronic components require ESD-safe corrugated packaging to prevent damage from static electricity during shipping and handling. Using conductive or dissipative materials, anti-static coatings, and foam inserts, ESD packaging shields delicate parts like circuit boards, sensors, and automotive electronics from harmful electrical charges. Proper grounding and specialized corrugated designs help reduce the risk of electrostatic buildup, ensuring product integrity. These protective solutions are essential for industries where even minor static discharge can lead to costly malfunctions or failures.

Eco-friendly corrugated packaging solutions help businesses reduce their environmental impact while maintaining durability and functionality. Using recyclable materials, biodegradable coatings, and water-based inks, sustainable packaging supports green initiatives without sacrificing strength. Lightweight and right-sized designs minimize waste and lower shipping costs, creating a more efficient and responsible supply chain. Sustainable corrugated packaging meets consumer expectations for eco-conscious products while complying with industry regulations.

Custom corrugated boxes designed for both retail and eCommerce provide versatility, allowing businesses to streamline their packaging strategy. Retail-ready boxes feature eye-catching branding, die-cut windows, and shelf-ready designs, while eCommerce-friendly packaging prioritizes durability, secure closures, and efficient shipping. Multi-purpose designs ensure products transition smoothly from warehouse to store shelves or direct-to-consumer delivery without compromising quality or presentation. By balancing protective elements with branding and sustainability, these boxes help businesses optimize costs while maintaining a seamless consumer experience.

Choosing the right corrugated material is critical for balancing cost, protection, and performance based on the product’s weight and fragility. Options like single-wall, double-wall, and triple-wall corrugated board provide varying levels of strength for different applications. Specialty coatings and moisture-resistant treatments can enhance durability for products requiring extra protection. The right material selection ensures that packaging meets industry standards while optimizing cost and efficiency.

Corrugated boxes are engineered to withstand rough handling, stacking pressure, and environmental exposure, ensuring products remain intact. Reinforced fluting, custom inserts, and heavy-duty closures provide added strength to protect against damage in transit and storage. Businesses shipping fragile, heavy, or high-value items require durable packaging to prevent costly returns or product loss. By incorporating impact resistance and load-bearing design, durable corrugated boxes deliver maximum protection with minimal waste.

Structural integrity is key for corrugated packaging, especially for heavy, bulk, or oversized products that require superior load-bearing capacity. Double-wall and triple-wall corrugated board provide enhanced stacking strength, preventing crushing during storage and transportation. Reinforced corners, cross-directional fluting, and specialized adhesives further improve the resilience of custom boxes. Strong packaging helps reduce the risk of damage, increases efficiency, and supports a safer supply chain.

Efficient packaging solutions help streamline the supply chain by reducing costs, improving handling, and maximizing storage space. Right-sized corrugated boxes, lightweight materials, and collapsible designs enhance logistics by cutting down on excess packaging and shipping expenses. Features like barcode integration, branding, and pallet optimization simplify inventory management and distribution. Optimized packaging ensures that products move seamlessly from production to retail or eCommerce fulfillment, reducing delays and improving profitability.

Temperature-sensitive products require corrugated packaging with insulated liners, moisture barriers, and thermal protection to maintain quality. Custom cold chain boxes with insulated inserts and gel packs help regulate internal temperatures for pharmaceuticals, food, and perishables. Packaging solutions that provide consistent temperature control ensure compliance with strict storage and transportation regulations. Corrugated cold chain packaging is designed for efficiency, sustainability, and superior product protection throughout distribution.

For additional solutions of corrugated boxes, including specialized or unique packaging needs, contact Brown Packaging. We can provide tailored solutions and guidance based on specific requirements, industry, and product characteristics, ensuring that your packaging needs are met effectively and efficiently.

The Edge Crush Test (ECT) evaluates the stacking strength of corrugated boxes, ensuring they can withstand vertical pressure during storage and transit. ECT-certified boxes are ideal for warehouse stacking, palletized shipments, and high-load packaging applications. Choosing the right ECT rating helps businesses prevent box collapse, product damage, and supply chain inefficiencies. This certification is widely used in eCommerce, automotive, food, and retail industries to ensure cost-effective yet durable packaging solutions.

The Mullen Burst Test measures the force required to rupture corrugated board, ensuring packaging can withstand pressure and rough handling. This certification is essential for shipping boxes, industrial packaging, and high-stress environments, where protection against punctures and bursts is critical. Packaging with high Mullen ratings is ideal for fragile products, heavy loads, and long-distance shipping, reducing the risk of product damage. Meeting Mullen Burst Test standards ensures that corrugated boxes provide maximum strength and durability in demanding supply chains.

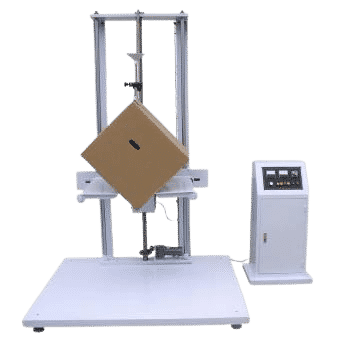

The Drop Test evaluates a corrugated box’s ability to withstand impacts by simulating real-world drops during handling and shipping. Boxes are tested from various heights and angles to assess structural integrity, cushioning, and product protection. This certification is crucial for eCommerce, automotive, electronics, and fragile product shipments to minimize damage. Meeting drop test standards ensures that packaging provides maximum impact resistance and secure product containment.

The Vibration Test measures how packaging performs under continuous movement, shaking, and transportation stress. Simulating road, rail, air, or sea transit, this test ensures that corrugated boxes protect products from shifting, loosening, or breakage over long distances. Industries like automotive, aerospace, and consumer electronics rely on vibration-tested packaging to prevent mechanical failures and structural weaknesses. Compliance with vibration testing reduces product returns and enhances overall supply chain efficiency.

The Compression Test determines a box’s ability to withstand vertical stacking pressure in warehouses, during transit, and in storage. High-compression strength ensures that boxes do not collapse under palletized loads or extended storage periods. Common in retail, eCommerce, and industrial shipping, this certification is essential for multi-box stacking and bulk packaging. Boxes with strong compression ratings improve storage efficiency and reduce product damage.

The Puncture Resistance Test assesses how well a corrugated box can withstand sharp objects, punctures, and accidental impacts. This test is essential for industries handling auto parts, industrial tools, medical devices, and heavy equipment where packaging may encounter sharp edges. Boxes with high puncture resistance prevent tearing, breaches, and exposure to external contaminants. This certification ensures secure transport and enhances product protection in high-risk conditions.

The Moisture Resistance Test evaluates how well a corrugated box resists humidity, condensation, and water absorption. Packaging exposed to coastal shipping, cold chain logistics, and damp storage environments must withstand moisture-related weakening. Boxes with moisture-resistant coatings, wax linings, or specialized adhesives pass this test to maintain structural strength and product safety. Ensuring moisture resistance is crucial for food, pharmaceuticals, and industrial materials.

The Shock Test simulates sudden impacts, drops, or handling mishaps to evaluate how well a box absorbs shock and sudden force. This test is critical for protecting fragile electronics, medical devices, and automotive components from damage. Corrugated packaging with shock-absorbing inserts, reinforced flaps, and multi-layered structures is tested to meet impact protection standards. Meeting shock test requirements ensures products arrive in optimal condition despite handling fluctuations.

The Incline Impact Test measures how well packaging withstands tilting, shifting, and sliding impacts during warehouse movement and loading operations. This test ensures that boxes do not collapse or cause product instability when subjected to angled forces. Commonly used in automotive, aerospace, and industrial supply chains, this certification helps prevent transportation hazards and reduces product damage. Properly tested packaging guarantees safe handling in high-movement environments.

ASTM standards establish strength, durability, and performance benchmarks for corrugated packaging, ensuring it meets burst strength, edge crush resistance (ECT), and impact resistance requirements. These certifications guarantee that shipping and storage boxes can handle real-world conditions, protecting products from damage. Industries like automotive, aerospace, and electronics rely on ASTM-rated packaging to ensure safe transit and regulatory compliance. Meeting these standards helps businesses maintain consistent quality and reduce packaging failures.

Designed by Amazon, Frustration-Free Packaging (FFP) ensures that boxes are easy to open, fully recyclable, and protective for eCommerce shipments. This certification eliminates excess materials, hard-to-remove seals, and unnecessary plastic, improving sustainability. Meeting FFP standards helps brands optimize shipping efficiency, reduce waste, and enhance the customer unboxing experience. Companies that comply with Amazon’s Frustration-Free Packaging Program can benefit from reduced fulfillment costs and improved consumer satisfaction.

FSC-certified packaging guarantees that the corrugated material is sourced from responsibly managed forests, supporting sustainability and environmental conservation. Businesses that use FSC-certified corrugated boxes demonstrate their commitment to eco-friendly and ethical sourcing practices. This certification is widely recognized in retail, food, beauty, and eCommerce industries, appealing to environmentally conscious consumers. FSC-compliant packaging helps reduce deforestation while ensuring high-quality, sustainable packaging solutions.

Similar to FSC, the SFI certification ensures that packaging materials come from forests managed with responsible environmental, social, and economic practices. Companies choosing SFI-certified corrugated boxes demonstrate a commitment to sustainable sourcing, biodiversity conservation, and responsible logging practices. This certification provides a competitive advantage for brands prioritizing eco-friendly supply chain solutions. It also helps businesses comply with green packaging initiatives and consumer sustainability expectations.

ISO 9001 certification ensures that a company follows a rigorous quality management system (QMS) to maintain consistent packaging quality and production standards. Certified corrugated packaging suppliers must meet strict manufacturing, process control, and customer satisfaction criteria. This certification is essential for industries requiring highly regulated packaging, such as pharmaceuticals, electronics, and automotive. It also enhances a company’s reputation, supply chain reliability, and commitment to excellence.

Contact Brown Packaging: Ensuring that your corrugated packaging meets industry standards and compliance regulations is critical for product protection, supply chain efficiency, and customer satisfaction. From drop tests and vibration resistance to moisture protection and thermal stability, our packaging solutions are rigorously tested to meet the highest performance requirements. Whether you need ASTM, FSC, ISO, ISTA, or other compliance certifications, we help you navigate the complexities of packaging regulations to ensure your boxes perform reliably in shipping, storage, and retail environments. Contact Brown Packaging today to discuss your specific packaging requirements and let our experts create a solution that meets industry standards and your business needs.

Corrugated Box Customization

Custom corrugated boxes make a difference by providing superior protection, precise sizing, and structural integrity for a wide range of industries, from automotive and aerospace to food and pharmaceuticals. By tailoring packaging to specific product requirements, businesses can improve durability, efficiency, sustainability, and brand visibility, ensuring products remain secure throughout manufacturing, storage, shipping, and final delivery.

Digital printing is a plate-free process that applies ink directly to corrugated boxes, making it ideal for high-quality graphics, rapid production, and cost-effective short runs. It offers fast turnaround, easy customization for multiple SKUs, and minimal setup costs, making it perfect for prototyping, on-demand printing, and variable designs. Digital print is best suited for small to medium runs requiring flexibility, vibrant visuals, and quick design changes without the high costs of traditional printing methods.

Flexographic printing is a high-speed, cost-effective printing method that uses custom printing plates and fast-drying inks to transfer designs onto corrugated boxes. It is ideal for large production runs, offering consistent quality, Pantone color accuracy, and lower cost per unit at high volumes. Flexo print is best suited for simple to moderately detailed graphics, large-scale packaging, and repeat orders where efficiency and affordability are key.

Lithographic printing is a premium, high-resolution printing method that transfers ink from a plate to a rubber blanket before applying it to corrugated boxes. It delivers photo-quality graphics, sharp details, and vibrant colors, making it ideal for luxury packaging, retail displays, and brand-focused designs. Litho print is best suited for high-end packaging, large format prints, and projects requiring superior image clarity and a polished finish.

Clear and effective design ensures that key messages, product details, and company information are easily understood. Strong visual communication enhances the user experience, reducing confusion and making the packaging more functional.

Graphic design ensures that essential product details, such as specifications, features, and usage guidelines, are clearly presented. Proper layout and organization make it easy for customers and retailers to find the information they need quickly.

Step-by-step assembly, usage, or handling instructions are more effective when designed with clear visuals and easy-to-read text. Well-designed instructions reduce errors, improve customer satisfaction, and enhance product usability.

Packaging must highlight important safety information to prevent misuse, hazards, or regulatory non-compliance. Clear warnings with bold text, icons, or color-coded alerts ensure visibility and user awareness.

Proper color contrast improves readability, visibility, and brand impact, ensuring that text and graphics stand out. Well-balanced color schemes make packaging more visually appealing and easier to understand.

Choosing the right font size and typography ensures that text is legible from different viewing distances. Proper font selection enhances clarity, branding consistency, and accessibility across various packaging formats.

Sharp, high-quality images enhance the overall aesthetic of packaging and provide a professional look. High-resolution graphics help showcase product details, branding elements, and promotional visuals with clarity and precision.

From custom finishes and specialty coatings to interactive QR codes and multi-language printing, we provide tailored graphic design solutions to meet your unique packaging needs. Contact Brown Packaging today to explore design options that enhance branding, functionality, and overall packaging impact.

Using only the necessary amount of corrugated material ensures cost savings while maintaining durability. This approach helps businesses reduce excess packaging and maximize performance without compromising protection.

Structural integrity ensures that boxes withstand weight and pressure when stacked, preventing crushing or damage. Reinforced designs, such as double-wall construction and load-bearing fluting, enhance stability for storage and shipping.

Structural elements such as tamper-evident seals, interlocking flaps, and reinforced closures help prevent theft and unauthorized access. Secure packaging is essential for industries requiring compliance, safety, and product integrity.

Efficient designs help reduce material waste, optimize recyclability, and lower carbon footprints. By using eco-friendly materials and right-sized packaging, businesses can meet sustainability goals while maintaining durability.

Structural design enhances the usability and practicality of packaging, ensuring it meets handling, storage, and transportation needs. Features like easy-open designs, reinforced corners, and custom inserts improve both protection and user experience.

Custom corrugated boxes can include protective inserts, tamper-evident closures, perforations, or resealable designs for added convenience. These features enhance product security, accessibility, and overall packaging effectiveness.

A well-designed structural layout enhances the customer’s first interaction with the product, creating a seamless and memorable unboxing process. Features like easy-open tear strips, custom inserts, and premium interior printing add excitement and reinforce brand identity. Thoughtful unboxing design helps improve customer satisfaction, product presentation, and perceived value. A smooth and engaging experience encourages brand loyalty, social sharing, and repeat purchases.

Every product has unique packaging needs, and our structural design solutions ensure functionality, protection, and efficiency tailored to your requirements. Whether you need custom reinforcements, space-saving designs, or an enhanced unboxing experience, we provide innovative solutions to optimize your packaging. Our team specializes in maximizing durability, sustainability, and cost-effectiveness for a wide range of industries. Contact Brown Packaging today to discuss your packaging goals and let us help you create the perfect solution.

Triple-wall corrugated boxes provide maximum strength, durability, and impact resistance, making them suitable for extremely heavy-duty applications. Used in industrial, automotive, and bulk shipping, these boxes can handle palletized loads, machinery parts, and large equipment. Their rigid structure and high compression resistance ensure that even the heaviest products remain secure in transit and storage.

A-flute corrugated material has the thickest and most cushioned fluting, providing superior shock absorption and stacking strength. It is commonly used for fragile items, industrial packaging, and applications requiring additional padding. With approximately 36 flutes per foot, A-flute is ideal for shipping boxes that prioritize durability and impact protection.

B-flute corrugated has a thinner profile with about 49 flutes per foot, offering a good balance between strength and space efficiency. This flute type is often used for die-cut boxes, retail packaging, and packaging for canned goods, where rigidity is needed but bulkiness is minimized. B-flute is excellent for precision printing and compact packaging without compromising durability.

C-flute is the most commonly used corrugated material, providing a good mix of strength, cushioning, and printability. With about 41 flutes per foot, it offers versatility for shipping, eCommerce, and retail packaging. C-flute is a great choice for general-purpose boxes, balancing durability with cost-effectiveness.

E-flute corrugated is thin and compact, featuring approximately 94 flutes per foot, making it ideal for high-quality printing and retail packaging. It provides a smooth surface for detailed graphics while maintaining good compression strength for lightweight products. E-flute is commonly used for luxury packaging, electronics, and smaller consumer goods that require a premium look.

F-flute is even thinner than E-flute, with about 128 flutes per foot, offering superior printability and a sleek design. Often used for high-end retail, cosmetic, and food packaging, it provides a refined appearance without sacrificing rigidity. F-flute is ideal for branding-focused packaging where aesthetics and structural integrity are both priorities.

Spot UV coating enhances specific areas of a design by adding a glossy, raised effect over selected text, logos, or graphics. This contrast between matte and gloss elements creates a high-end, eye-catching appearance that draws attention to branding details. Spot UV is often used for luxury packaging, promotional displays, and premium retail boxes to add visual and tactile interest.

Litho-lamination applies high-quality, offset-printed sheets to corrugated surfaces, creating photo-quality graphics and vibrant colors. This process is ideal for high-end retail packaging, POP displays, and premium product boxes where detailed, high-resolution printing is essential. Litho-lamination enhances branding with crisp images, rich colors, and a smooth, professional finish.

We offer a range of custom finishes to enhance both the visual appeal and functionality of your corrugated packaging. Whether you need embossing, foil stamping, soft-touch coatings, or specialty textures, we can create the perfect look for your brand. Our team ensures that your packaging is both visually striking and durable, making a lasting impact on customers. Contact Brown Packaging today to discuss your finishing options and create a solution that meets your brand’s needs.

Corrugated Packaging Services

Add more value to your product and packaging experience with our in-house capabilities and services. Work one on one with a project specialist throughout the entire packaging process with services designed to help you meet your goals and maximize your results, while providing you with peace of mind.

Our in-house structural design service provides expertly engineered corrugated packaging solutions, including custom inserts designed for maximum product protection and stability. With a team of experienced engineers, we develop complex, innovative designs that enhance functionality, durability, and efficiency. By optimizing materials, space, and structural integrity, we create cost-effective, high-performance packaging with tailored inserts to secure and protect products during shipping and storage.

Our in-house graphic design services ensure that your custom corrugated boxes are both visually striking and effectively branded. Whether you provide your own artwork or need us to create custom graphics, logos, and layouts, our team ensures high-quality printing with sharp details, vibrant colors, and professional finishes. From product information and branding to eye-catching retail displays, we design packaging that enhances visibility, readability, and customer engagement while maintaining structural integrity.

Our sampling and prototyping services provide both physical and digital samples, allowing you to test and refine your custom corrugated box design before mass production. Physical prototypes help assess structural integrity, material durability, and fit, while digital proofs ensure accurate branding, colors, and print alignment. This process minimizes risks, reduces costs, and ensures that your final packaging meets both functional and aesthetic expectations before full-scale production. Plain and digital printed samples available for our in-house services.

Our product and material testing services ensure that your custom corrugated boxes meet the highest standards for strength, durability, and performance to minimize product loss and damage. We design packaging to pass your desired tests, including drop, vibration, compression, and moisture resistance, ensuring your products remain secure throughout the supply chain. Our team also assists in obtaining industry certifications such as ASTM, ISTA, and FSC, helping you meet regulatory requirements and reinforce customer confidence. By optimizing materials and structure, we help you reduce shipping risks, lower return rates, and enhance overall packaging reliability.

Interested In Custom Corrugated Boxes?

What Clients Say

With over 30+ years experience in the packaging industry, we have helped small to large brands from all different industries with their packaging needs. Learn what our customers say about us, as we strive to deliver our customers exceptional service from concept to completion.