Home » Compression Set and Recovery in Foam Cushioning Materials

Compression Set and Recovery in Foam Cushioning Materials

In packaging, foam isn’t just about initial protection — it’s about maintaining performance over the entire shipping or storage cycle. Compression set and recovery characteristics determine whether foam continues to provide shock absorption after being loaded, stacked, or stored for long periods.

What Is Compression Set?

- Definition: The permanent deformation a foam retains after being compressed for a defined time and temperature.

- Why It Matters: A foam that takes a high compression set loses thickness and cushioning capability, leaving products more vulnerable to impact damage.

- Typical Measurement: Reported as a percentage loss of original thickness after the load is removed.

Recovery Rate and Load Retention

- Recovery Rate: How quickly foam returns to its original dimensions after load removal.

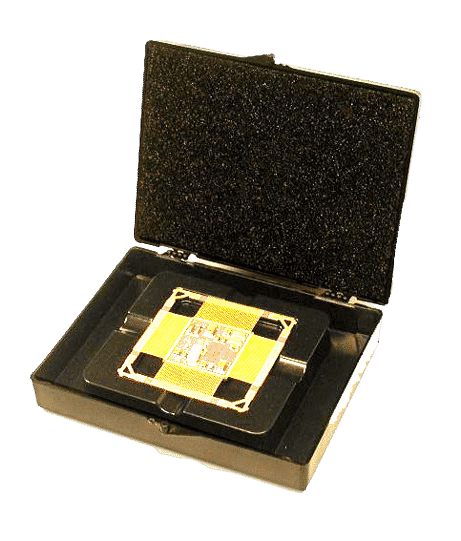

- Load Retention: The ability to maintain performance over repeated load cycles — crucial for returnable and reusable packaging.

- High recovery and load retention mean the foam can be used multiple times without replacement.

Factors Affecting Compression Set

- Foam Chemistry:

- Crosslinked PE typically offers lower compression set than non-crosslinked.

- PU foams may be softer but often exhibit higher permanent deformation under load.

- Density: Higher-density foams resist deformation better but may be heavier and costlier.

- Environmental Conditions: Heat and humidity accelerate compression set in most foam materials.

Testing and Standards

- ASTM D3574 Test D: Measures compression set under specified load and temperature.

- ASTM D3574 Test B1/B2: Evaluates indentation force deflection for load-bearing properties.

- ASTM D1055: For rubber-like cellular materials, often applicable to certain elastomeric foams.

Design Strategies

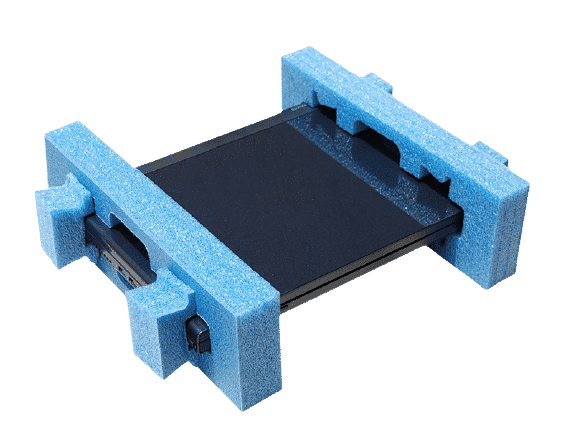

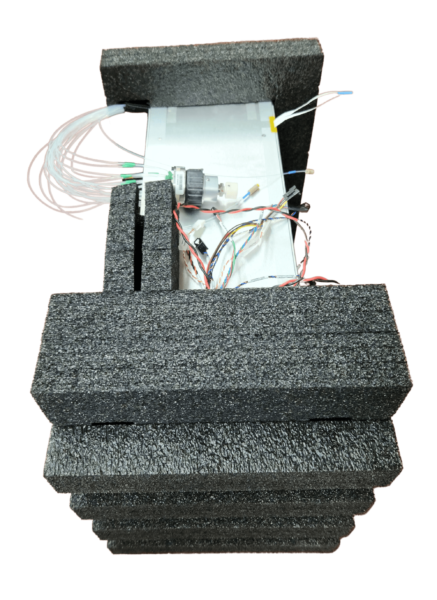

- Load Distribution: Use ribbed or contoured inserts to spread weight across more surface area.

- Material Blends: Combining foams with different recovery characteristics can balance softness and durability.

- Replace on Schedule: In closed-loop systems, track cycle counts and replace foam before performance degradation risks product safety.

References

ASTM International. (2021). ASTM D3574-21: Standard test methods for flexible cellular materials—Slab, bonded, and molded urethane foams. ASTM International. https://www.astm.org/d3574-21.html

ASTM International. (2014). ASTM D1055-14: Standard specification for rubber cellular sheeting—Closed cell. ASTM International. https://www.astm.org/d1055-14.html

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset, review performance, and implement cost-saving

Home » Compression Set and Recovery in Foam Cushioning Materials