Protective Packaging Solutions

Custom Expanded Polyethylene Foam

Our custom expanded polyethylene (EPE) foam products are engineered to meet your unique requirements. With exceptional shock absorption and impact resistance, our EPE foam products are suitable for a variety of applications, including protective packaging, cushioning, and insulation.

Protective Packaging Solutions

Custom Expanded Polyethylene Foam

Our custom expanded polyethylene (EPE) foam products are engineered to meet your unique requirements. With exceptional shock absorption and impact resistance, our EPE foam products are suitable for a variety of applications, including protective packaging, cushioning, and insulation.

What is Expanded Polyethylene?

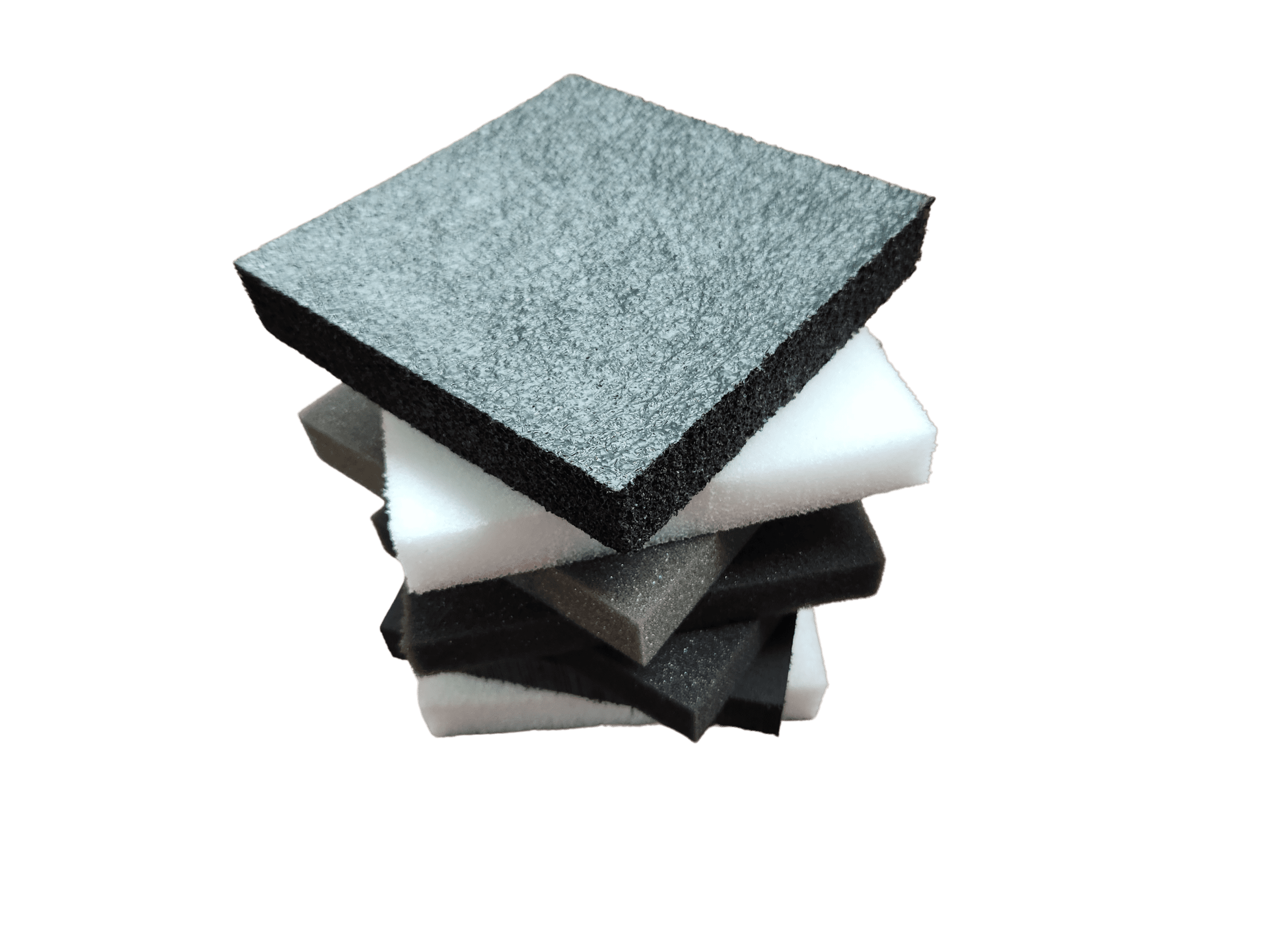

Expanded polyethylene (EPE) foam is a lightweight and flexible material that is commonly used for a variety of applications. It is made by expanding polyethylene through a controlled heating and cooling process. The result is a foam material that has a soft and cushioned texture, providing excellent shock absorption and impact resistance.

EPE foam is known for its versatility, as it can be easily molded and shaped to fit various applications. It is also a widely used material in the packaging industry, as it provides excellent protection for fragile items during shipping and handling. Additionally, EPE foam is commonly used in the construction industry, in automotive parts, sports equipment, and even in orthopedic devices

One of the most significant benefits of EPE foam is its durability. It is resistant to moisture, chemicals, and UV radiation, making it an ideal material for use in outdoor environments. EPE foam is also widely recyclable, making it an eco-friendly choice for many businesses. Overall, expanded polyethylene foam is a reliable and cost-effective material that can be tailored to meet specific needs and requirements.

EPE Options and Features

Select from a variety of foam options and features such as insert design, density, additives and size.

EPE can be easily cut and shaped into various sizes and shapes, making it an adaptable material for multiple uses such as cushioning, packaging, and insulation. The process involves using cutting tools such as knives, saws, or hot wires.

To improve its functionality and properties, the foam can be combined with other materials like adhesives, fabrics, or films. This technique, known as laminating, allows for the creation of water-resistant or thermally insulated foam products.

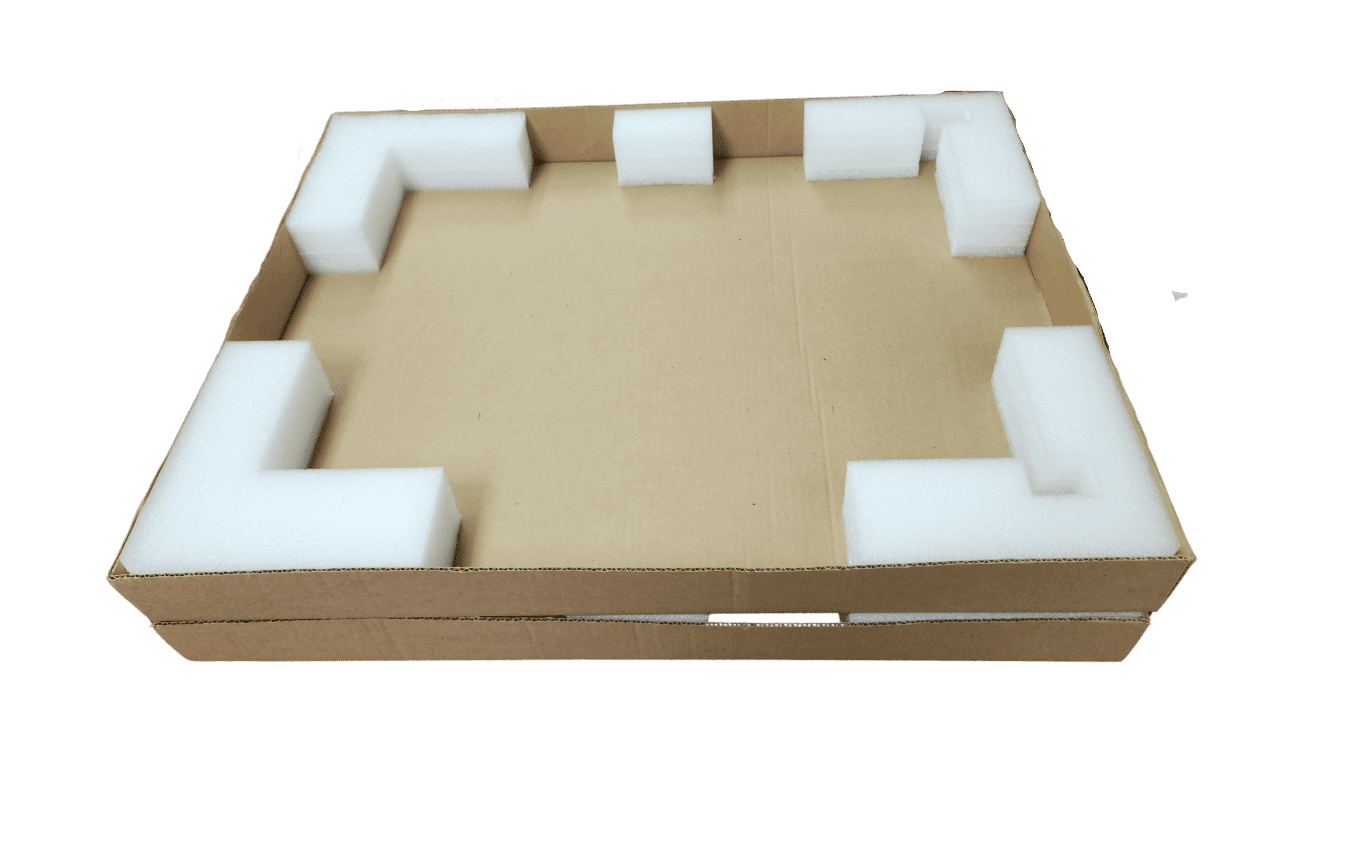

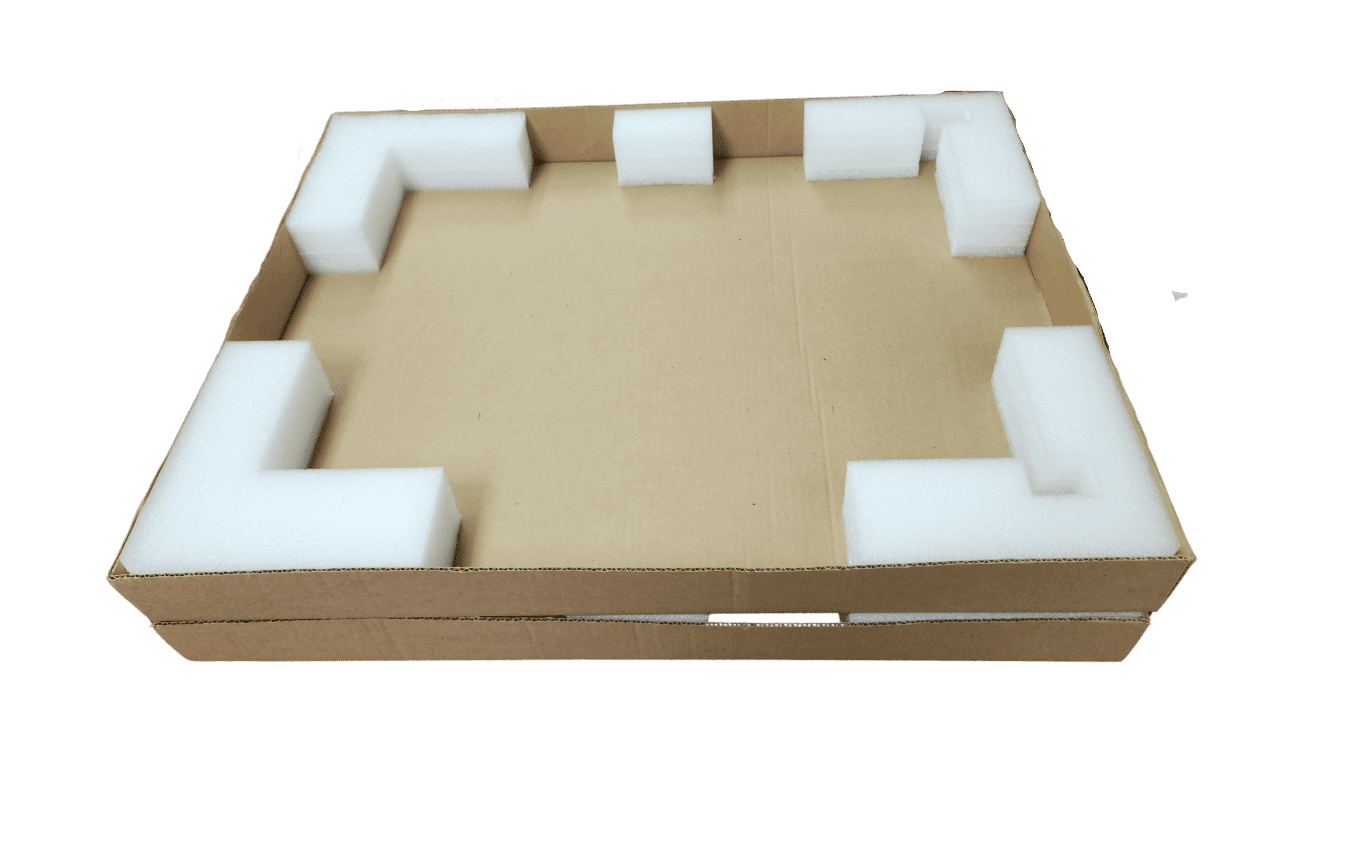

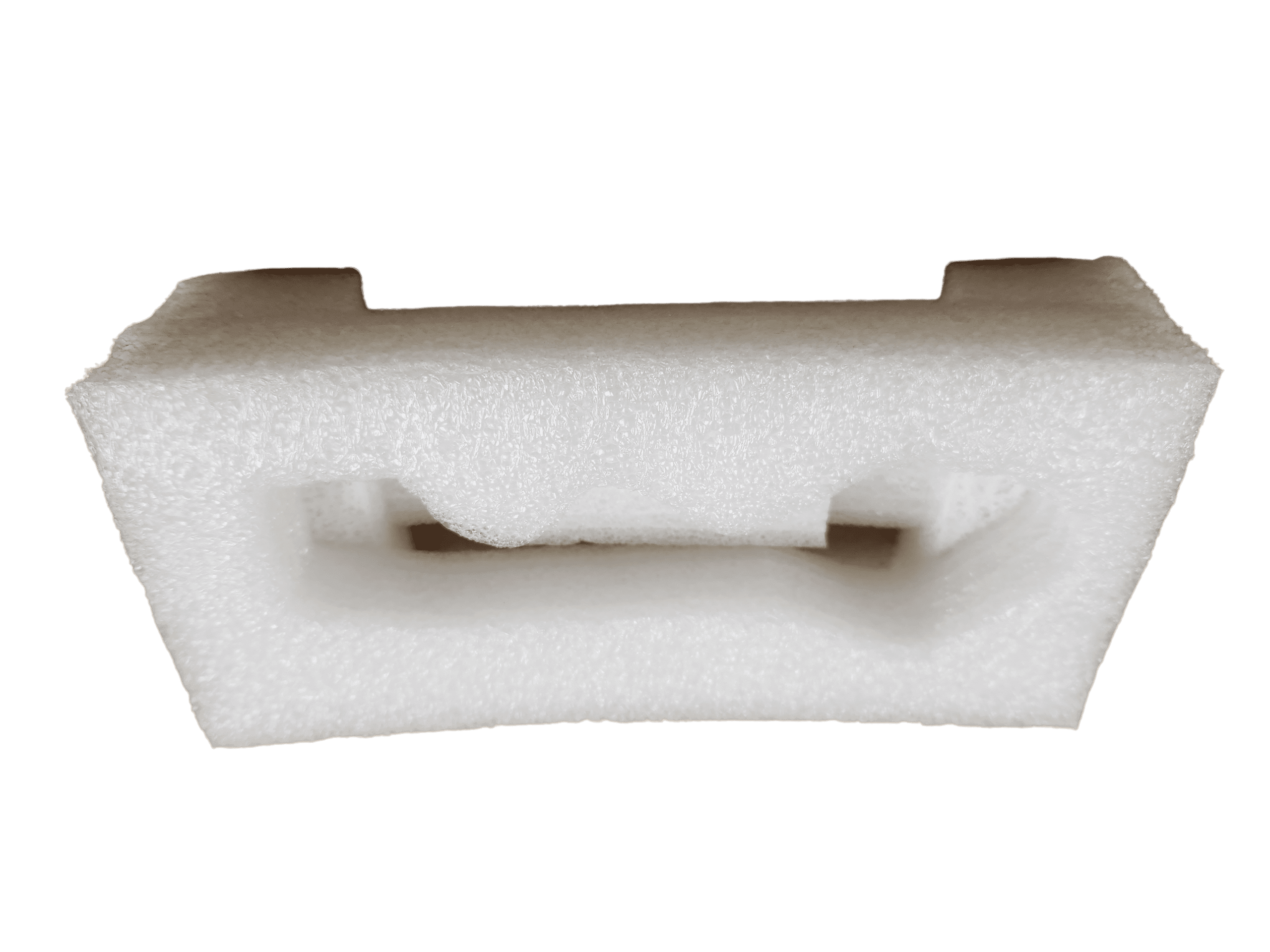

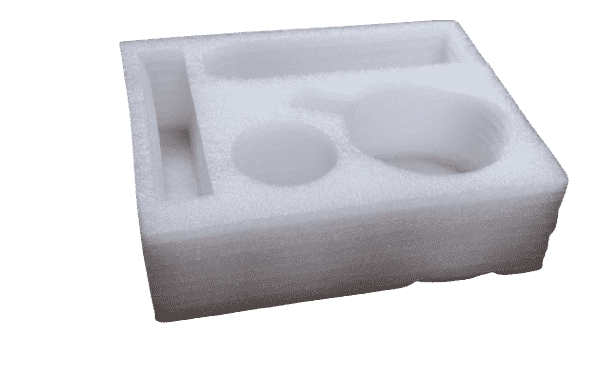

EPE can be designed to fit specific products by creating custom inserts. The inserts can be designed to provide protection, support, or organization for the product. This customization option is useful for creating foam inserts for toolboxes, cases, or packaging. The inserts can also be designed with specific shapes or cutouts to accommodate the product’s shape or accessories.

The foam can be printed with logos, designs, and labels using different printing methods like digital printing or screen printing. Printing on the foam surface provides an opportunity to promote brands or products, giving them a professional appearance.

To fit specific branding or product requirements, the foam can be customized with different colors. Coloring agents are used to achieve a uniform color throughout the material, making it a suitable option for creating packaging, displays, and other products.

Patterns or designs can be added to the foam surface using embossing techniques, which add a decorative touch to products. Embossing can also create textures and patterns, improving the product’s visual appeal while providing a tactile experience for users.

The foam can be cut into specific shapes and sizes using a die-cutting machine. Die cutting is useful for creating foam inserts or padding that fits a specific product or application. Additionally, it can be used to create custom shapes and sizes for packaging or displays.

One way to customize the foam is through adhesive bonding, which involves bonding it to different surfaces. This creates a permanent or temporary bond and is useful for creating customized products like foam gaskets or foam tapes.

CNC routing allows the foam to be precisely cut and shaped, making it suitable for creating intricate designs and shapes. CNC routing is useful for creating foam inserts or parts for various industries like automotive or aerospace.

The foam can be customized using compression molding. This method involves compressing the foam into a mold under high pressure and temperature, creating complex shapes and parts. Compression molding is ideal for creating protective padding for sports equipment or medical devices.

To enhance the foam’s properties, its surface can be treated with coatings such as flame retardants or anti-static agents. Surface treatment can also improve the foam’s durability, making it suitable for harsh environments.

Another way to customize the foam is through welding. The foam can be welded together using hot air, ultrasonic, or radio frequency welding. This technique is useful for creating customized foam products such as bags, cases, or covers.

EPE can be customized using thermoforming. This process involves heating the foam and molding it into different shapes using a vacuum or pressure. Thermoforming is ideal for creating foam products such as trays, containers, or displays.

Expanded polyethylene can be co-extruded with other materials, such as plastics or rubbers, to create multi-layered products with improved functionality and properties. This customization option is useful for creating products such as weather-stripping or seals.

This foam can be cut with a high-pressure water jet, which provides a precise and clean cut. This technique is useful for creating foam products with intricate shapes and designs, such as foam inserts for toolboxes or cases.

The surface of the foam can be engraved with designs, logos, or other markings using laser engraving or other techniques. This customization option is useful for creating customized products such as foam displays or signage.

antimicrobial agents can be added to prevent the growth of bacteria, mold, or other microorganisms. This technique is useful for creating foam products for healthcare or food-related industries.

The foam can be treated with flame retardants to make it less flammable or self-extinguishing. This customization option is useful for creating foam products for industries such as transportation or construction, where fire safety is critical

Interested In Custom Expanded Polyethylene?

Frequently Asked Questions

Yes, we do offer recyclable and other sustainable materials. Contact us and we can go over sustainable options with you that best fit your project.

Order minimums vary from project to project, it usually depends on the type of packaging, design, size and desired materials. Contact us and we will evaluate the best options for your packaging needs.

Lead times can vary depending on your display style, design, quantity, materials and other factors. To get an accurate lead time for your project, contact us and a packaging expert will assist you.

Alternatives to expanded polyethylene, include polyurethane, polyethylene, and many others. Visit our custom foam page to view all styles.

Shipping is free to all Southern California businesses. Fees are generally added to orders outside of Southern California or if you need a rush order.