Protective Packaging Solutions

Custom Expanded Polystyrene Foam

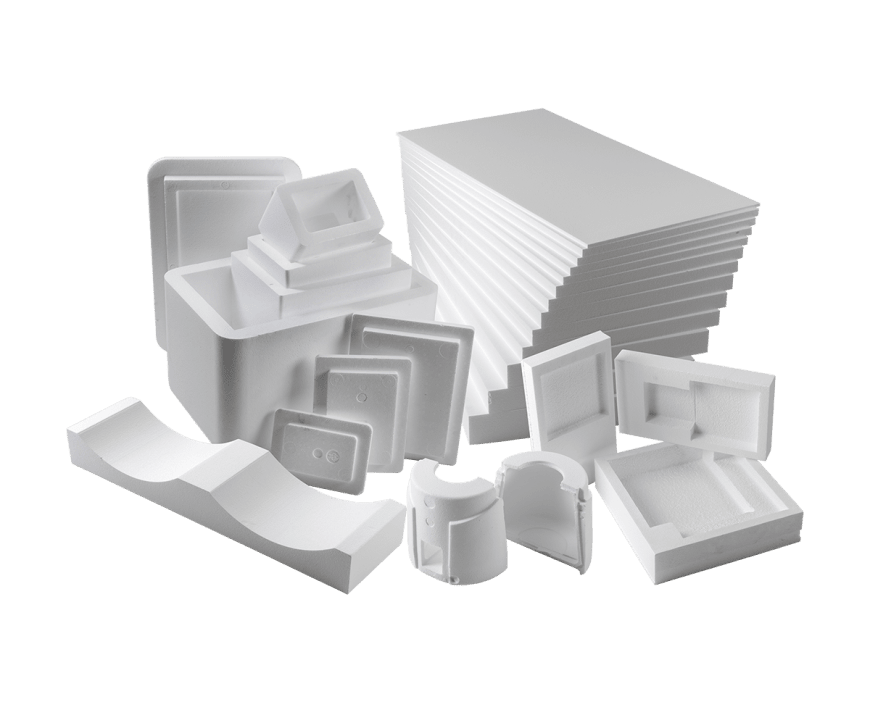

Our custom expanded polystyrene (EPS) foam packaging solutions are the ideal choice for protecting your products during shipping and storage. EPS is a versatile and cost-effective material that offers superior shock absorption and insulation properties, making it a popular choice for packaging delicate items such as electronics, medical devices, and food products.

Protective Packaging Solutions

Custom Expanded Polystyrene Foam

Our custom expanded polystyrene (EPS) foam packaging solutions are the ideal choice for protecting your products during shipping and storage. EPS is a versatile and cost-effective material that offers superior shock absorption and insulation properties, making it a popular choice for packaging delicate items such as electronics, medical devices, and food products.

What is Expanded Polystyrene?

Expanded polystyrene (EPS) is a lightweight foam material that is commonly used in protective packaging applications due to its excellent insulation, low density, high compressive strength, thermal insulation and shock absorption properties.

EPS inserts can be custom-designed to fit the specific product being shipped, ensuring a secure fit that minimizes movement during transit. It can be cut to fit irregularly shaped items, or designed to hold multiple items in place. This flexibility makes it a popular choice for protecting delicate and fragile items such as electronics, medical devices, beverages, and food products.

Additionally, EPS is a durable and long-lasting material that can withstand repeated impacts, making it ideal for items that require frequent shipping and handling. Overall, EPS is a reliable and efficient choice for companies looking to ensure that their products arrive safely and securely at their destination.

EPS Options and Features

Select from a variety of foam options and features such as insert design, density, additives and size.

By altering the amount of polystyrene beads used during manufacturing, the density of the foam can be adjusted. This can impact the compressive strength and shock absorption properties of the foam, allowing it to be tailored to the specific needs of the product being packaged.

EPS can be easily cut and shaped to fit specific products or packaging requirements. This can be done using hot wire cutters or CNC machines, allowing for precise and consistent cuts.

Sizing customization involves cutting and shaping expanded polystyrene (EPS) to fit specific products or packaging requirements. This can be done using hot wire cutters or CNC machines, allowing for precise and consistent cuts. Sizing customization can help to minimize movement within the packaging and reduce the risk of damage or breakage during transit. It is a common customization option for EPS packaging and is widely used across various industries.

Coatings or films can be applied to the surface of the foam to improve its resistance to moisture, abrasion, and other environmental factors. Coatings can also be used to enhance the appearance of the foam, making it more aesthetically pleasing for retail display purposes.

Inserts, such as molded pulp or plastic trays, can be designed to fit specific products and securely hold them in place during transit. Inserts can help to minimize movement within the packaging, reducing the risk of damage or breakage.

EPS can be laminated with other materials, such as corrugated board or plastic, to improve its strength and durability. Lamination can also provide additional protection against moisture and other environmental factors.

Flame retardant chemicals can be added to improve its fire resistance. This is particularly important for products that are being shipped by air, where strict regulations require packaging materials to meet certain safety standards.

Foam can be coated with adhesives to create a strong bond between the foam and other packaging materials, such as cardboard boxes or plastic films. This can help to ensure that the product stays in place during transit, reducing the risk of damage or breakage.

EPS can be customized to provide vibration damping properties, which can help to minimize the impact of vibrations and shocks during shipping and handling. This can be achieved through the use of special coatings or materials that are added during the manufacturing process.

Can be perforated to create tear-away sections or ventilation holes, which can improve the functionality and usability of the packaging. For example, tear-away sections can be used to create easy-to-open packaging for consumers, while ventilation holes can be used to improve the air flow and freshness of perishable products.

Surface texture can be adjusted to provide additional grip or slip resistance, depending on the needs of the product being packaged. This can be achieved through the use of special molds or tooling during the manufacturing process.

EPS can be combined with other materials, such as foam rubber or felt, to create hybrid materials that offer additional functionality or properties. For example, combining EPS with foam rubber can create a material that provides both shock absorption and vibration damping properties.

Interested In Custom Expanded Polystyrene?

Frequently Asked Questions

Yes, we do offer recyclable and other sustainable materials. Contact us and we can go over sustainable options with you that best fit your project.

Order minimums vary from project to project, it usually depends on the type of packaging, design, size and desired materials. Contact us and we will evaluate the best options for your packaging needs.

Lead times can vary depending on your display style, design, quantity, materials and other factors. To get an accurate lead time for your project, contact us and a packaging expert will assist you.

Alternatives to expanded polystyrene, include polyurethane, polyethylene, and many others. Visit our custom foam page to view all styles.

Shipping is free to all Southern California businesses. Fees are generally added to orders outside of Southern California or if you need a rush order.