Custom Full Overlap Corrugated Boxes

Our Full Overlap (FOL) corrugated boxes are designed for maximum durability, ideal for protecting heavy, oversized, or high-value items during transit. With overlapping flaps that reinforce the structure, these boxes offer enhanced crush resistance, edge protection, and stacking strength. FOL boxes are fully customizable in size, board grade, and print, making them a versatile solution for industrial shipping, ecommerce fulfillment, and specialized packaging needs.

What Is A Full Overlap (FOL) Corrugated Box?

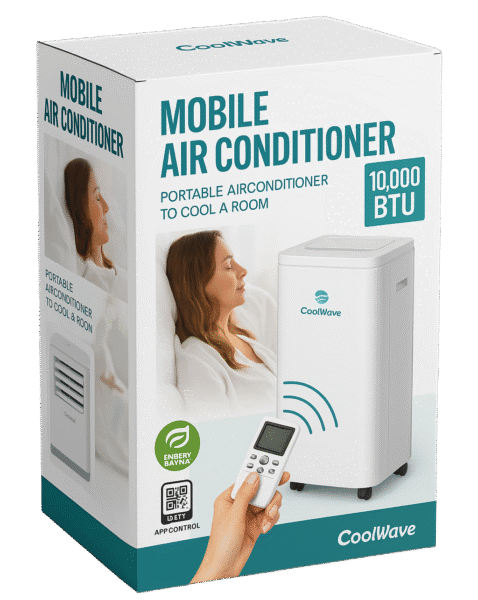

A Full Overlap (FOL) box, also known as a fully overlap box, is a style of corrugated packaging where the top and bottom flaps completely overlap, providing added crush resistance, puncture protection, and overall strength. This makes them ideal for heavier or fragile products—such as electronics, glassware, ceramics, or machinery parts—that need reliable packaging through rough handling or long-distance transit.

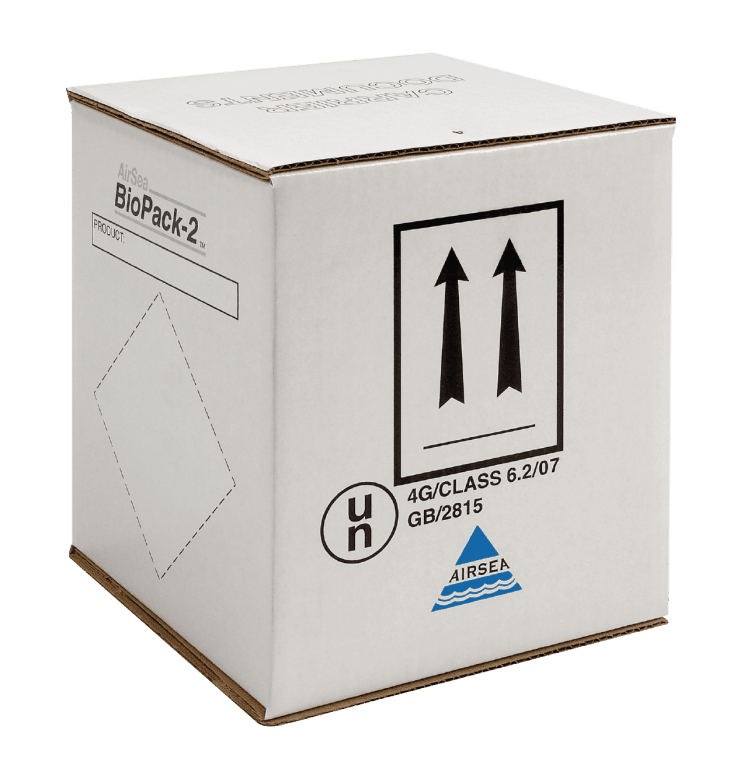

The overlapping flaps reinforce the box’s structure and edges, making it especially well-suited for industrial shipments and ecommerce fulfillment. FOL boxes are also fully customizable in size and print, giving companies the flexibility to incorporate branding, handling instructions, or compliance markings. With their durability and adaptability, FOL boxes are a dependable solution for a wide range of shipping, storage, and display applications.

Full Overlap Box Customization

Choosing the right features, materials, and print options for your Fully Overlap (FOL) box is essential to aligning performance with your business goals. A well-optimized FOL box not only protects your product—it also maximizes efficiency, enhances branding, and helps control costs across your packaging operation.

Structural design for Full Overlap (FOL) corrugated boxes prioritizes edge strength, stacking durability, and impact resistance. The fully overlapping flaps provide reinforced protection for heavy or fragile items, making them ideal for industrial shipping and storage.

The defining feature of FOL boxes is the full overlap of the flaps, which reinforces the top and bottom edges of the box. This added thickness provides superior crush resistance, especially during stacking or impact. It’s a crucial benefit for industries shipping heavy machinery, dense items, or delicate components, where edge damage is a leading cause of in-transit failure.

Buyers must match the corrugated board grade—such as single-wall, double-wall, or triple-wall—to the product’s weight and fragility. FOL boxes perform best when paired with the right ECT (Edge Crush Test) or burst strength rating to withstand high pressure. Selecting the correct wall strength ensures durability during loading, handling, and warehousing without unnecessary cost or excess material.

A key reason for choosing FOL boxes is their excellent load-bearing performance. The overlapping flaps provide a solid base and top for stacking stability, reducing the risk of collapse or deformation in warehouses or freight trucks. When designed properly, FOL boxes help optimize pallet patterns and reduce product damage in vertical storage environments.

FOL boxes pair well with custom inserts, foam, or dividers that secure contents inside. Structural design must ensure a tight, tailored fit between the product and the box to prevent shifting during transit. Whether using engineered foam for fragile items or corrugated partitions for organized parts, FOL construction complements internal protection systems.

FOL boxes are often used in manual or semi-automated packaging environments, so ease of sealing, opening, and handling is important. The extended flaps can accommodate heavy-duty tape, staples, or glue for a secure closure. Structural design should also account for hand holes, lift tabs, or labeling panels to make the box more functional in real-world conditions.

Graphic design for Full Overlap (FOL) corrugated boxes plays a key role in both branding and usability. With their broad overlapping flaps, FOL boxes offer ample surface area for clear logos, handling instructions, and visual hierarchy that supports fast identification and proper orientation during transit. Whether for industrial equipment or retail display, well-executed graphic design enhances brand visibility while reinforcing professionalism. Smart layout choices also help optimize multi-panel designs, ensuring that your messaging remains consistent from packing line to delivery. Effective design isn’t just aesthetic—it improves functionality and strengthens trust with every shipment.

Print options for Full Overlap (FOL) corrugated boxes allow businesses to combine rugged protection with impactful branding. Whether you’re shipping heavy equipment or fragile goods, your packaging can still serve as a powerful visual tool. FOL boxes can be printed using digital, flexographic, or lithographic methods—each offering different advantages in detail, volume, and cost efficiency. From bold logos to handling instructions and product visuals, custom print enhances both functionality and brand recognition in every shipment.

Best for short runs and high-variation designs, digital printing allows fast turnaround with crisp detail and full-color graphics. It's ideal for businesses looking to test new designs, personalize shipments, or maintain flexibility without committing to large print plates. Digital is also excellent for ecommerce or specialty packaging where visual appeal matters at low to mid volumes.

A go-to method for high-volume production, flexographic printing uses custom plates to deliver cost-effective, repeatable print across thousands of boxes. It's suited for single-color to multi-color prints, especially when speed and consistency are key. Flexo is commonly chosen for logistics, industrial, and branded shipping applications where clear, bold labeling is needed at scale.

For brands seeking premium visual presentation, lithographic (or litho-laminate) printing offers photo-quality finishes and high-end polish. It’s typically used when sharp graphics and vibrant colors are critical—such as in retail-ready packaging or high-value product shipments. Litho provides a top-tier appearance without compromising the protective strength of FOL construction.

Integrated die-cut handles make FOL boxes easier to lift and maneuver, especially for bulky or heavy contents. This feature is ideal for manual handling environments or retail-ready formats where customer convenience matters.

For added durability, reinforced corners provide extra support during stacking and impact. This customization is popular in industrial and ecommerce applications where packaging may face rough handling.

Whether made of foam, corrugated, or molded pulp, custom inserts help secure internal contents and prevent shifting. This is especially useful for fragile, high-value, or multi-component items.

For added strength, FOL boxes can be manufactured using double-wall or triple-wall corrugated board. These options improve compression resistance and are well suited for heavy-duty shipments.

FOL boxes can be customized to work with staples, heavy-duty tape, glue, or strapping, depending on your shipping method. The right closure ensures load stability and tamper resistance during transport.

Beyond standard sizes, FOL boxes can be optimized to match unique product dimensions, reducing wasted space and improving palletization. Precise sizing also contributes to shipping efficiency and lower costs.

Space for compliance information, handling instructions, or barcodes can be built into the design. This ensures packages are ready for regulated distribution, especially in industries like automotive, electronics, or hazmat logistics.

Additional customization options allow your Full Overlap (FOL) boxes to meet highly specific operational, branding, or regulatory needs. From ventilation holes for moisture-sensitive items to interior print for elevated unboxing experiences, we help you go beyond standard features. You can integrate lot coding, branded closures, or RFID tagging for better traceability and inventory control. Whether you need unique opening mechanisms, stack indicators, or enhanced pallet integration, we tailor solutions to your product and supply chain demands. Contact Brown Packaging to explore what’s possible—our team will help you build a box that works harder for your business.

Custom Corrugated Box Applications & Solutions

Understanding the applications, solutions, and compliance standards for Full Overlap (FOL) boxes ensures your packaging meets both performance and regulatory demands. From specialized industry use to strict testing protocols, each factor plays a role in delivering functional, cost-efficient, and reliable packaging tailored to your business needs.

Full Overlap boxes offer rigid protection and clean presentation for retail supply chains handling heavier or bulkier products. Their structure minimizes damage in transit, which is critical for preserving shelf-ready appearance. FOL boxes are often customized with branding and barcodes to streamline retail operations. They're a practical choice for retailers needing both strength and visual consistency.

Ecommerce shipments face harsh handling, and FOL boxes provide the durability and puncture resistance needed to protect contents door to door. Their overlapping flaps shield products from drops, compression, and improper stacking. Combined with branded print and secure sealing, FOL boxes enhance both delivery protection and unboxing experience. This makes them ideal for shipping high-value or fragile items in online retail.

Furniture often has irregular shapes, weight, and delicate finishes—FOL boxes solve these challenges with enhanced crush resistance and custom sizing. They're used to package everything from flat-pack pieces to small accent furniture, protecting against corner and surface damage. Reinforced edges keep the packaging intact during handling, especially when palletized. This packaging format offers peace of mind for both bulk deliveries and single-piece shipments.

From microwaves to refrigerators, FOL boxes offer essential protection for appliance manufacturers and distributors. Their double flap construction supports large, heavy products while limiting vibration, corner impact, and shifting. These boxes often integrate foam inserts, edge protectors, or ESD-safe packaging for electronic components. It’s a packaging solution built for heavy-duty logistics and high-value contents.

FOL boxes are a staple in industrial shipping due to their strength, stacking performance, and custom fit potential. They handle everything from heavy machine parts to fragile assemblies, often paired with internal bracing or foam dunnage. Their design protects valuable inventory from load crush and warehousing hazards. This makes them ideal for manufacturing supply chains with demanding conditions.

Electronics require packaging that controls movement and minimizes impact—FOL boxes deliver both through tight enclosures and reliable crush resistance. When combined with antistatic liners or ESD foam, they support the safe transport of circuit boards, modules, and sensitive devices. Their box structure supports clean stacking and labeling, ideal for warehouses and distribution centers. This is a go-to option when damage mitigation is non-negotiable.

Beverage shipments—especially in bulk—demand structural integrity and moisture resistance, which Full Overlap boxes provide with ease. Their reinforced design helps prevent sidewall collapse, critical when handling cans, bottles, or multi-pack units. When combined with dividers or inserts, they protect against breakage and shifting during transport. It’s a strong solution for brewers, distributors, or retailers needing safe, high-volume delivery.

For Aerospace and defense applications, FOL boxes are engineered to meet strict durability standards and withstand harsh conditions. Their overlapping panels provide redundancy in protection, particularly for high-value components or tools. Combined with cushioning materials, FOL packaging ensures mission-critical items are safeguarded through handling, storage, and transit. This level of reliability is essential in defense and aviation logistics.

Bicycles benefit from the rigid structure and secure closure of FOL boxes, which protect frames and components during transit. These boxes can be custom-sized to hold full bikes or parts with protective inserts to prevent shifting and scratching. Outer print customization helps maintain brand visibility and compliance with shipping standards. They're an efficient option for manufacturers, distributors, and DTC bike brands.

From fitness gear to team equipment, sporting goods often vary in size, weight, and shape—making FOL boxes a reliable choice. The overlapping flaps provide added edge protection, while the design accommodates internal foam or corrugated inserts to secure items in place. Ideal for both ecommerce and retail channels, they reduce returns by minimizing damage in transit. Sporting goods brands benefit from a protective box that also supports strong branding.

Computer components are sensitive to both impact and static, and FOL boxes can be customized to manage both risks. Whether it’s a desktop tower or peripheral gear, their rigid design resists compression and pairs well with ESD foam, edge protection, and custom inserts. The flat surfaces offer space for technical labeling, branding, or handling instructions. It's a protective solution trusted for industrial shipments and ecommerce fulfillment alike.

Contact Brown Packaging: Custom corrugated boxes serve a wide range of industries, providing durability, protection, and branding for countless applications. From luxury goods and subscription boxes to industrial equipment and electronics, we offer tailored packaging solutions designed to meet your product’s specific needs. Whether you require impact-resistant shipping boxes, eco-friendly alternatives, or retail-ready displays, our team ensures your packaging is both functional and visually appealing. Contact Brown Packaging today to discuss your packaging needs and let us help you create the perfect solution for your business.

For cost-effective branding, FOL boxes with single-color print offer a clean, professional appearance while keeping production budgets in check. Ideal for bulk shipments or internal logistics, this option delivers clarity and consistency across all packaging. It's a reliable solution for companies that want brand recognition without added complexity.

Multi-color print expands visual impact with vibrant graphics, branding elements, or handling instructions. This option is perfect for companies prioritizing shelf presence, presentation, or detailed messaging. Whether using flexographic or digital print, it allows for more creative control across panels while retaining the FOL’s protective design.

FOL boxes can be engineered to convert into temporary displays, combining structural integrity with presentation value. Tear-away panels or custom die-cuts transform your box into a point-of-sale solution, streamlining transit-to-shelf transitions. It’s a great fit for retail promotions, seasonal displays, or wholesale environments where packaging must do more than just protect.

At their core, Full Overlap boxes are built for durable shipping performance. The overlapping flaps reinforce the box against crushing and edge damage, making them ideal for heavy or high-value shipments. From industrial to ecommerce applications, they’re a reliable workhorse for secure transit across tough supply chains.

Tamper-evident features such as security tape, locking tabs, or special closures can be integrated into FOL box designs. These additions protect contents from unauthorized access and build consumer trust in transit or on shelf. Especially critical for regulated products or high-value goods, this solution boosts both compliance and peace of mind.

FOL boxes can be lined or fitted with ESD-safe foam and materials to protect sensitive electronics from static damage. When paired with ESD bags or inserts, they create a complete anti-static packaging system ideal for shipping computer components or medical devices. It’s a trusted solution for clients with high-tech or static-sensitive products.

FOL boxes can be lined or fitted with ESD-safe foam and materials to protect sensitive electronics from static damage. When paired with ESD bags or inserts, they create a complete anti-static packaging system ideal for shipping computer components or medical devices. It’s a trusted solution for clients with high-tech or static-sensitive products.

With a reinforced structure and adaptable panel layout, FOL boxes are ideal for multi-purpose use—from shipping to storage to retail display. Custom inserts or adjustable partitions allow one box to handle a variety of SKUs or product types. It’s a smart choice for operations that value flexibility and long-term utility.

FOL boxes can be manufactured using double-wall, triple-wall, or high-performance corrugated board based on the weight, fragility, or handling needs of your product. You can also choose finishes like kraft, white-top, or coated stock to meet both visual and structural requirements. This level of customization ensures your box meets specific load and performance standards.

Smart sizing, CAPE-optimized layouts, and reinforced corners make FOL boxes ideal for reducing freight costs and improving stacking during transit. Their strength supports pallet efficiency and reduces product damage, helping streamline both outbound and return logistics. The result is a more efficient supply chain and lower total cost per shipment.

FOL boxes can be tailored for cold chain logistics with moisture-resistant coatings, inner insulation, or sealed liners. Their structural integrity holds up under refrigeration, freezing, or climate-controlled transit, making them suitable for perishable goods or medical equipment. A critical solution when temperature control and external durability are both required.

Looking for something more specific? Contact Brown Packaging for custom-engineered FOL solutions tailored to your product, supply chain, or compliance needs. We’ll help you build the right box—from print to performance.

The Edge Crush Test measures a box’s ability to withstand crushing along its edges—critical for maintaining structural strength in stacked or palletized loads. This is a key indicator of how well a box will perform in warehouse storage and transit environments.

The Mullen Test evaluates resistance to internal pressure by measuring how much force the corrugated board can withstand before bursting. It’s often used to assess puncture resistance and toughness, especially for items that might shift or press outward during shipment.

Drop testing simulates real-world handling by evaluating a box’s ability to protect contents from impact when dropped from various heights and orientations. It helps ensure that your packaging can withstand mishandling without compromising product integrity.

The Vibration Test replicates the conditions of trucks or conveyors to determine how a box holds up under continuous movement and jostling. It validates whether packaging can protect its contents throughout long-distance or high-volume distribution.

Compression testing determines how much vertical force a box can handle before collapsing. It’s crucial for palletized loads or stacking in warehouses, where lower-performing boxes may buckle under weight.

This test measures a corrugated box’s ability to resist sharp object penetration—useful for packaging products with pointed edges or when shipping alongside mixed freight. A strong score here minimizes risk of tears, holes, and product exposure.

Moisture resistance is assessed through a variety of tests that determine how well a box maintains strength when exposed to humidity, condensation, or temperature shifts. It’s especially relevant for cold chain logistics or damp shipping environments.

Shock testing evaluates how well packaging protects contents from sudden impacts, such as during drops, bumps, or hard landings. It’s essential for fragile or sensitive goods like electronics or glassware.

This test simulates the effect of a sliding impact—where a box hits a surface or another object at an angle. It’s used to verify structural durability in transit situations where collisions or shifting pallets may occur.

ASTM International sets globally recognized benchmarks for corrugated packaging performance, including tests for strength, durability, and environmental resistance. Using materials and packaging designs that meet ASTM standards ensures consistency, reliability, and compliance across all phases of your supply chain.

Frustration-Free Packaging, developed by Amazon, focuses on packaging that’s easy to open, recyclable, and protective enough for direct shipping. Meeting FFP guidelines can reduce damage claims, lower returns, and streamline your products’ integration into major e-commerce platforms.

The Forest Stewardship Council (FSC) certification verifies that the paper materials used in your packaging are sourced from responsibly managed forests. FSC-labeled corrugated packaging supports your brand’s sustainability goals and appeals to eco-conscious buyers.

Sustainable Forestry Initiative (SFI) certification ensures fiber materials are sourced with a focus on forest conservation, biodiversity, and responsible harvesting practices. Choosing SFI-certified packaging can reinforce corporate responsibility and align with environmental compliance programs.

Our ISO 9001 certification reflects our commitment to consistent quality management systems in packaging design, sourcing, and manufacturing. It ensures that every corrugated box you receive meets defined performance, compliance, and customer satisfaction benchmarks.

For specialized compliance needs—such as industry-specific regulations, export requirements, or custom audit standards—contact Brown Packaging. We’ll work with you to ensure your corrugated packaging meets the exact standards and specifications required for your application.

Full Overlap Packaging Services

Add more value to your product and packaging experience with our in-house capabilities and services. Work one on one with a project specialist throughout the entire packaging process with services designed to help you meet your goals and maximize your results, while providing you with peace of mind.

- Structural Design

- Graphic Design

- Samples and Prototyping

- Product and Material Testing

- Fulfillment and Assembly

Our structural design services ensure your Full Overlap (FOL) box performs under real-world conditions. We focus on maximizing load-bearing strength, crush resistance, and dimensional precision for your product’s weight and fragility. Every design is tailored to your application—whether you’re shipping bulky equipment or fragile components. Optimized geometry, flap orientation, and board selection are all engineered to minimize failure during transit and storage.

Professional graphic design for FOL boxes does more than brand your packaging—it communicates function, care, and quality. We can apply your existing artwork or create original graphics that align with your branding and packaging needs. Our team enhances readability, shelf appeal, and regulatory clarity through clean layout and purposeful visuals. Whether you’re aiming for minimal or bold, we help your box stand out and support your brand identity.

With our sampling and prototyping service, you can validate your packaging before full production. We produce true-to-spec samples using the actual materials, print methods, and cuts—so you can confirm performance, fit, and visual impact. This reduces risk and ensures everyone from procurement to fulfillment is aligned. It’s your opportunity to test and refine without costly errors.

We offer product and material testing to make sure your FOL box meets the demands of your supply chain. Tests include edge crush, drop, moisture resistance, and more—ensuring structural integrity and regulatory compliance. Our team helps interpret the results and advises improvements when needed. Whether you’re packaging electronics or heavy machinery, we make sure your packaging holds up.

Streamline your operation with our fulfillment and assembly capabilities. We can handle kit packing, insert placement, and palletization, reducing your labor burden and improving supply chain speed. Pre-assembled or partially assembled solutions ensure quick deployment and product protection from the outset. This service helps you scale efficiently and meet tight delivery windows.

Interested In Fully Overlap Corrugated Boxes?

Frequently Asked Questions

Yes, we do offer recyclable and other sustainable materials. Contact us and we can go over sustainable options with you that best fit your project.

Order minimums vary from project to project, it usually depends on the type of packaging, design, size and desired materials. Contact us and we will evaluate the best options for your packaging needs.

Lead times can vary depending on your display style, design, quantity, materials and other factors. To get an accurate lead time for your project, contact us and a packaging expert will assist you.

Alternatives to FOL, include HSC, RSC, STE, RTE, RETT, and many others. Visit our corrugated box page to view all styles.

Shipping is free to all Southern California businesses. Fees are generally added to orders outside of Southern California or if you need a rush order.

Yes, we have the most common and standard sizes boxes for sale. Contact us to see whether your desired size is available in standard or custom.