Computer Hardware & Accessory Packaging

Protecting sensitive electronics takes more than a standard box—it takes precision, performance, and packaging built around your product. From laptops and keyboards to cables, drives, and displays, our solutions are engineered to ship smarter, protect better, and present cleaner. Get the packaging that works as hard as your hardware.

Why Computer Hardware & Accessory Packaging Matters

Effective packaging is essential for protecting sensitive components like keyboards, internal parts, and cables from damage during shipping, handling, and storage. These items are often fragile or electrostatically sensitive, which means even minor impacts or static exposure can cause performance issues or total failure. Using antistatic foam, custom-fitted inserts, and protective polybags helps ensure each product arrives intact and ready for use.

Packaging also plays a strategic role in customer experience and brand perception. For buyers, especially in the tech space, clean presentation and well-structured internal layout communicate professionalism and quality. A thoughtful unboxing experience adds credibility and reinforces trust in the product. Whether you’re shipping through retail, eCommerce, or B2B distribution, the right packaging enhances product value, reduces return rates, and supports long-term customer loyalty.

Computer Packaging Products & Customization

Our computer hardware and accessory packaging is designed to protect sensitive components while enhancing functionality, efficiency, and brand impact. With a wide range of structural options, foam materials, print methods, and custom features, each solution is tailored to meet your exact product and shipping requirements.

Corrugated boxes are the standard for safely shipping computer hardware and accessories at scale. Their durability and customizability make them ideal for protecting products like keyboards, power supplies, and cable kits. They’re cost-effective, stackable, and ready for both eCommerce and bulk distribution.

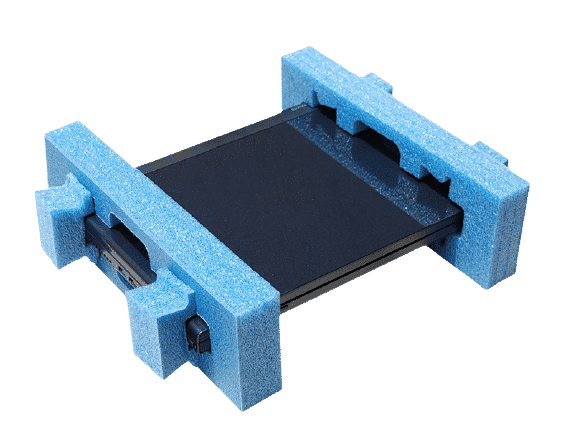

Fabricated foam provides custom-fit protection for fragile and high-value components like hard drives, graphics cards, and CPUs. Each insert is engineered to minimize movement and absorb impact during transit. Perfect for businesses that need secure, professional presentation with high-performance cushioning.

Polybags are ideal for organizing and protecting non-fragile items like cords, manuals, and accessories. Lightweight and efficient, they prevent scratches and keep components clean and contained. Great for kit assembly and warehousing where speed and simplicity matter.

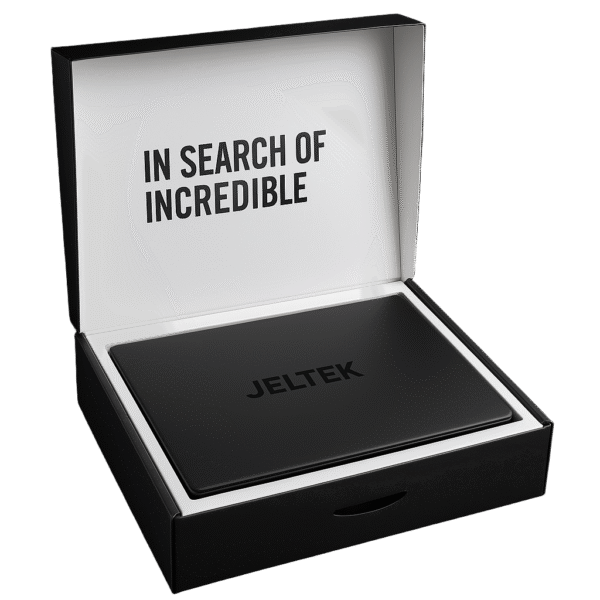

Rigid boxes bring a premium look and feel to packaging for high-end peripherals, gift sets, or product launches. Their solid structure enhances both protection and unboxing experience. Ideal for companies looking to impress customers and reinforce brand value.

Antistatic foam is critical for protecting static-sensitive electronics such as memory modules, PCBs, and internal components. It dissipates static buildup while offering shock absorption. For electronics manufacturers, it’s an essential part of safe, compliant packaging.

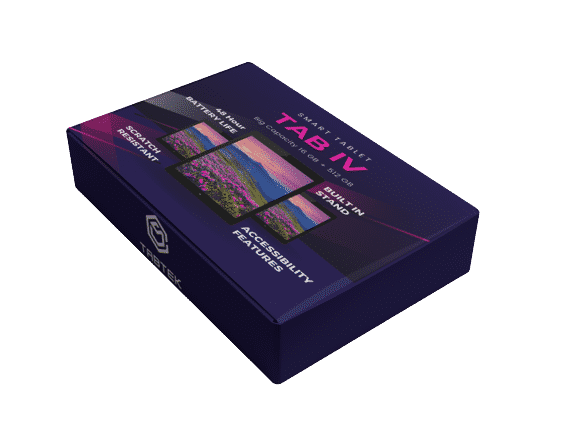

Folding cartons are perfect for retail display of accessories like webcams, USB hubs, or software add-ons. With full-color print and custom shapes, they deliver both protection and shelf-ready branding. Lightweight and versatile, they’re easy to assemble and efficient to store.

Anti static poly bags provide a protective barrier against electrostatic discharge during handling and shipping. Commonly used for small electronics, cables, and exposed connectors, they’re reliable and easy to use. An essential tool for safe, organized component packaging.

Conductive boxes combine physical protection with built-in static shielding, perfect for shipping exposed hardware like processors and boards. They help prevent ESD damage while maintaining a clean, branded appearance. Excellent for B2B shipments or OEM fulfillment.

Thermoformed trays provide precision-molded protection and organization for smaller accessories like USB drives, mice, or adapters. They keep items neatly in place, reducing handling damage and improving kitting speed. A smart solution for bundle packaging or retail kits.

Dissipative foam helps protect static-sensitive components by safely channeling charges away from the product. It’s ideal for internal device components, repair kits, or integrated systems requiring both cushioning and ESD control. A must for brands shipping high-end or fragile devices.

POP displays showcase computer hardware and accessories at the point of sale, drawing attention to featured products or promotions. Designed to hold mice, headphones, or bundled items, they enhance in-store visibility and drive last-minute purchases. Fully customizable for branding and layout needs.

In addition to our core offerings, we provide a wide range of specialty packaging products to meet the diverse needs of computer hardware and accessory brands. Whether you need crates, in-store signage, pallet sheets, edge protectors, or other custom solutions, we can help source and design what fits your operation. Contact Brown Packaging to explore tailored options for your application.

Whether you're producing packaging in small batches or at scale, selecting the right print method makes all the difference. Digital printing allows for fast updates and lower quantities, while flexographic and lithographic printing provide excellent quality for larger runs with consistent branding. Matching the method to your needs helps you balance cost, turnaround, and visual impact.

Protecting sensitive electronics starts with choosing the right foam for the job. PE and EPS provide firm support for heavier hardware, while PU and EPE offer softer cushioning for delicate parts. The right material ensures products stay secure during transit without adding unnecessary bulk or cost.

Efficient packaging starts with a structure that’s built around your product—not the other way around. Whether you’re shipping single units or complete kits, smart structural design ensures protection, reduces waste, and improves packing speed. It also helps control freight costs by optimizing space and stacking strength.

Great packaging doesn’t just protect—it communicates. Clear, purposeful graphic design strengthens your brand, guides the end user, and elevates the perceived value of your product. Consistent visuals across boxes, cartons, and inserts help reinforce trust and recognition in both retail and B2B channels.

Well-designed inserts keep everything in place—preventing product damage, improving organization, and creating a cleaner unboxing experience. Whether foam, paperboard, or thermoformed, inserts ensure that keyboards, mice, chargers, and accessories arrive exactly as intended. They also make kitting, co-packing, and repackaging more efficient.

Functional details like auto-lock bottoms, tear strips, dust flaps, or reinforced handles can transform packaging into a more user-friendly and secure solution. These small enhancements improve how your packaging performs in warehouses, during shipping, and on the shelf. The right features make handling faster, safer, and more intuitive for everyone involved.

Additional Customization

Beyond standard options, many packaging programs benefit from specialty add-ons or tailored solutions designed around specific product, shipping, or user experience needs. Whether it’s unique coatings, layered materials, or integrated branding features, the right custom touches can elevate both protection and presentation. Contact Brown Packaging to explore advanced customization options for your hardware and accessory packaging.

Computer Packaging Applications & Solutions

Our computer hardware and accessories packaging solutions are built to meet the demands of fragile, high-value, and static-sensitive products. With options tailored to specific applications—like laptops, monitors, keyboards, and wiring—we help ensure protection, compliance, and efficient handling across every stage of your supply chain.

Laptop shipping boxes are designed to protect devices from impact, vibration, and pressure during transit. With options like custom inserts, corner protection, and anti-static liners, these boxes ensure safe delivery for everything from consumer models to enterprise fleets.

Desktop computers require durable, form-fitting packaging that accounts for internal weight and delicate components. Reinforced corrugated structures, foam blocking, and double-wall panels help reduce shock and protect against damage in shipping and storage.

Keyboards and mice benefit from custom foam inserts or molded trays that hold them securely in place without scratching or shifting. Whether shipping individually or as part of a bundle, packaging is designed to enhance both protection and unboxing experience.

Monitors are fragile and bulky, making precision foam framing, reinforced corners, and ESD-safe materials essential for protection. Packaging is optimized to minimize screen movement and absorb impact without adding unnecessary bulk.

Cables and wires are best packaged using polybags, coiled trays, or organized compartments to avoid tangling and damage. Clear labeling and segmented inserts streamline kitting, while antistatic options help protect signal-sensitive products.

Compact and delicate, webcams need small-scale custom inserts that balance product visibility with secure cushioning. Folding cartons or rigid boxes with thermoformed trays are ideal for retail display and safe transport.

Internal components like drives, RAM, and power supplies require antistatic protection, form-fitted foam, and conductive packaging. These solutions are built for both OEM and aftermarket distribution where product integrity and compliance matter.

Speakers and microphones vary widely in shape and sensitivity, making custom foam and rigid inserts critical for secure placement. Packaging focuses on vibration control and presentation, particularly for premium audio products or bundled kits.

From accessories like docking stations and external drives to niche components or bundled kits, many packaging needs fall outside standard categories. Specialized solutions are available for unique shapes, sensitive materials, or multi-part assemblies. Contact Brown Packaging to discuss packaging options tailored to your specific application.

Sensitive electronics like motherboards, memory, and internal components are vulnerable to static damage during handling and transit. Packaging with antistatic, conductive, or dissipative materials helps neutralize charges and protect product integrity. Implementing ESD-safe solutions is critical for quality control and warranty cost reduction.

Hardware and accessories often require tamper-evident features to ensure product authenticity, safety, and customer confidence. Options like security seals, locking flaps, and perforated tear strips help prevent unauthorized access and show clear signs of interference. These features are especially valuable in retail, regulated, or high-value shipments.

Computer hardware packaging must withstand drops, compression, and environmental stress without compromising product safety. Reinforced corrugated boxes, foam interiors, and edge protection offer reliable defense against damage. Durable packaging reduces returns, improves brand reputation, and supports safe long-distance shipping.

Well-designed packaging can significantly streamline the manufacturing, warehousing, and fulfillment process. From flat-packed materials to optimized cube efficiency and palletization, smart packaging helps reduce storage costs and speed up handling. The result is better control over inventory, logistics, and total landed cost.

For tech products sold in retail environments, packaging must do more than protect—it must attract attention and drive sales. Packaging can be designed to integrate directly into POP displays, peg hooks, or shelf-ready trays, making restocking faster and more efficient. This enhances visibility and ensures a seamless transition from warehouse to retail floor.

Many hardware products are sold in bundles or require multiple components to be packed together efficiently. Custom inserts, trays, and multi-compartment packaging help keep everything organized and protected throughout the kitting process. This approach improves packing speed, reduces labor errors, and ensures a clean, professional presentation for the end user.

Packaging is often the first physical touchpoint with your brand—especially in DTC and retail environments. Thoughtfully designed graphics, textures, and structural elements elevate perceived value and strengthen brand recognition. For hardware and accessories, premium presentation helps create a lasting impression and supports customer loyalty and repeat purchases.

Not every packaging challenge fits in a box—literally or figuratively. From custom configurations to unique product demands, there are countless ways to enhance protection, efficiency, or brand experience. Contact Brown Packaging to explore additional solutions designed around your specific goals.

ISTA testing ensures your packaging can withstand real-world shipping hazards like drops, vibration, compression, and environmental stress. For computer hardware and accessories, ISTA-certified packaging helps prevent damage in transit and reduces returns. Meeting these standards gives you and your customers confidence in shipping performance and product protection.

ISO standards provide global benchmarks for quality, consistency, and safety in packaging design and production. For electronics packaging, relevant certifications—such as ISO 9001—support traceability, process control, and material compliance. Aligning with ISO standards ensures your packaging meets industry expectations and procurement requirements across markets.

RoHS compliance ensures packaging and components are free from restricted hazardous materials like lead and mercury. While originally a European directive, many U.S. companies adopt RoHS to align with retail and OEM requirements. It’s especially relevant for electronics packaging used near circuitry or sensitive components.

Many computer hardware shipments require clear country of origin labeling for import/export, retail compliance, or customs clearance. Proper labeling supports traceability and transparency across the supply chain. Accurate labeling also reduces the risk of shipment delays or regulatory issues.

Using “Made in USA” on packaging requires compliance with FTC guidelines, which mandate that products be “all or virtually all” made domestically. This applies not only to the product, but often to the packaging materials and production as well. Accurate claims help build trust and avoid regulatory risk.

Any environmental claims made on packaging—like “recyclable,” “biodegradable,” or “eco-friendly”—must comply with FTC Green Guides. These guidelines prevent misleading marketing and require clarity on what claims mean. Staying compliant ensures honest communication with customers and reduces legal exposure.

If you're shipping lithium batteries, power banks, or other hazardous computer hardware, your packaging may need to meet UN/DOT regulations. These include specific requirements for structure, labeling, and testing. Using compliant packaging helps avoid penalties, delays, and rejected shipments.

For hardware or accessories sold in California, packaging must comply with Prop 65 warning label requirements if certain chemicals are present. Even in small amounts, materials in cables, plastics, or coatings may trigger labeling obligations. Compliance helps avoid fines and retail pushback in one of the largest U.S. markets.

Computer Packaging Services

Add more value to your product and packaging experience with our in-house capabilities and services. Work one on one with a project specialist throughout the entire packaging process with services designed to help you meet your goals and maximize your results, while providing you with peace of mind.

We provide custom-engineered packaging structures designed specifically for computer hardware and accessories—no templates, no guesswork. Our solutions prioritize product protection, efficient palletization, and optimized material use, helping reduce damage and lower freight costs. It's how we help you avoid one-size-fits-all packaging and stay ahead of costly inefficiencies.

Our team combines retail-ready design expertise with technical packaging knowledge to bring your brand to life—without compromising production or compliance. From clean B2B visuals to high-impact retail graphics, we ensure your packaging makes the right impression. We don’t just add logos—we help you elevate your brand through packaging.

We offer rapid prototyping and sample development so you can see exactly how your packaging performs before scaling up. Whether you're validating fit, functionality, or shelf presence, we give you the tools to move forward with confidence. It’s a hands-on process that reduces risk and shortens decision cycles—a level of responsiveness many providers can’t match.

Our solutions are backed by rigorous in-house testing—including ISTA drop, compression, and vibration simulation—to ensure your packaging holds up in the real world. We also test foam types, static control materials, and other protective elements specific to electronics. When your products require performance you can prove, we deliver tested, validated results.

We offer packaging systems designed for streamlined kitting and assembly, helping you reduce labor costs and prevent packing errors. From internal trays to multi-compartment boxes, our designs support faster throughput and cleaner organization. Whether for direct shipping or co-packing operations, we help you save time while improving presentation.

Beyond the box, we support your entire packaging process—from low-volume production runs and UX sampling to regulatory guidance and fulfillment integration. Our flexibility, industry knowledge, and responsiveness set us apart from transactional vendors. If you're looking for a true packaging partner—not just a supplier—Brown Packaging is ready to support your next move.