Auto Parts & Accessories

Our custom auto parts and accessories packaging solutions are designed to protect and showcase products with options like corrugated boxes, folding cartons, blister packs, and more. We provide tailored packaging for both retail and eCommerce, ensuring durability during shipping and an eye-catching presentation on shelves. With our comprehensive packaging services, we help businesses create secure, high-quality packaging that enhances brand visibility and meets industry standards.

What is Auto Parts & Accessories Packaging

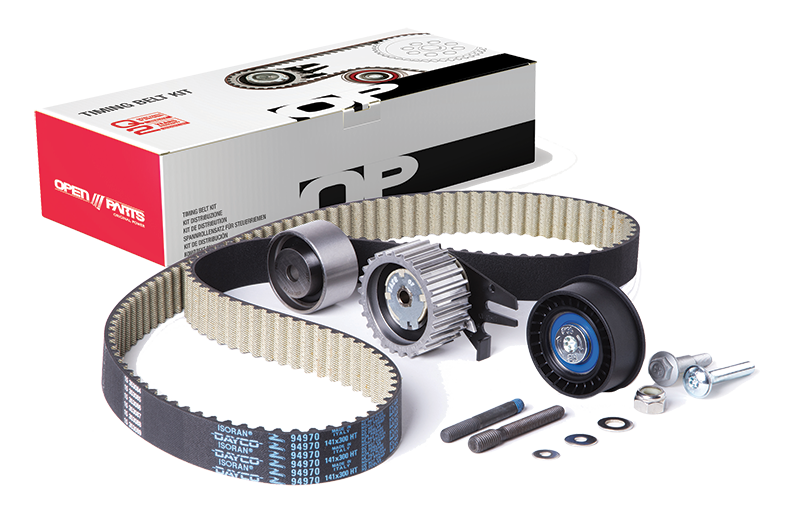

Our auto parts and accessories packaging is designed to provide superior protection and presentation for products of all sizes. We offer a range of solutions, including corrugated boxes, folding cartons, blister packs, and more, ensuring durability for shipping and an attractive display for retail. Whether for delicate components or heavy-duty parts, our packaging solutions safeguard items while enhancing brand recognition.

We cater to both retail and eCommerce markets, delivering packaging that meets industry standards and withstands transit challenges. Our custom packaging services allow businesses to create secure, high-quality designs that align with their branding and product needs, ensuring a professional and reliable packaging solution.

Auto Parts & Accessories Packaging Applications & Solutions

Our auto parts and accessories packaging applications include secure solutions for brake pads, car batteries, performance parts, and automotive fluids, designed to prevent damage and ensure safe transit. We offer custom packaging solutions like reinforced structures, moisture protection, tamper-evident designs, and sustainable materials to meet the needs of both retail and eCommerce businesses.

Applications

Brake pads and rotors require sturdy, impact-resistant packaging to prevent damage during shipping and storage. Reinforced corrugated boxes with protective inserts help secure these heavy components, reducing movement and ensuring they arrive in perfect condition. Custom branding and high-quality printing also enhance the professional presentation of these essential automotive parts.

Automotive fluids like motor oil, coolant, and transmission fluid demand secure, spill-proof packaging to prevent leaks. Corrugated boxes with inner compartments help stabilize fluid containers, reducing the risk of breakage in transit. Tamper-evident seals and regulatory labeling ensure product integrity and compliance with industry safety standards.

Wrenches, socket sets, and diagnostic tools require sturdy, wear-resistant packaging to protect against damage. Corrugated boxes with foam inserts or durable plastic cases offer long-term storage and protection. Clear labeling and instructional guides help customers quickly identify and use the right tools.

These fragile auto parts require secure, cushioned packaging to prevent cracks, scratches, or shattering. Corrugated boxes with custom inserts keep headlights and taillights stable, minimizing movement in transit. High-quality retail packaging also enhances shelf appeal and provides essential product details for buyers.

Products like wax, polish, and sprays need functional yet visually appealing packaging for both retail and eCommerce sales. Folding cartons and blister packs work well for smaller items, while corrugated boxes offer durability for bulk products. Custom branding and vibrant graphics help attract customers and improve shelf presence.

Turbochargers, exhaust components, and suspension kits require strong, protective packaging that withstands impacts and rough handling. Heavy-duty corrugated boxes with custom inserts ensure these high-performance parts remain secure during transit. Premium finishes and branded packaging also add value and elevate product presentation.

Car stereos, dash cams, and GPS devices require secure, theft-resistant packaging for retail and shipping. Rigid folding cartons and blister packs provide both product visibility and protection, ensuring electronics remain intact. Foam or molded inserts help absorb shocks and prevent internal movement during transit.

Floor mats, seat covers, and steering wheel covers need protective yet lightweight packaging for retail and eCommerce. Folding cartons, poly bags, or corrugated mailers help keep these items clean and neatly organized. Clear product descriptions and branding ensure customers easily identify the right fit for their vehicles.

Solutions

Buyers prioritize packaging that ensures auto parts remain intact during transit and storage. Reinforced corrugated boxes, shock-absorbing inserts, and heavy-duty materials help prevent damage from impacts, vibrations, and rough handling.

Custom inserts, dividers, and die-cut designs secure irregularly shaped or fragile components. Optimized packaging reduces movement, improving product safety while enhancing storage and display efficiency.

Auto parts, especially metal components, need protection against humidity and corrosion. Buyers look for moisture-barrier coatings, VCI (Volatile Corrosion Inhibitor) bags, and vacuum-sealed pouches to extend product lifespan.

With sustainability gaining importance, businesses seek recyclable, biodegradable, and FSC-certified packaging. Kraft corrugated boxes, minimalistic designs, and soy-based inks help reduce environmental impact while maintaining product integrity.

For products sold in stores, packaging must be visually appealing and easy to display. Buyers need options like high-quality printed folding cartons, hanging blister packs, and shelf-ready corrugated displays to enhance brand visibility.

To prevent theft and contamination, businesses require packaging with security seals, reinforced closures, and RFID or QR code tracking. This is especially crucial for high-value auto parts and aftermarket electronics.

Buyers look for packaging solutions that maximize storage and minimize shipping costs. Compact, right-sized, and collapsible designs help reduce waste while ensuring efficient warehouse management.

Online sales require packaging that balances durability and cost-effectiveness. Corrugated mailers, padded shipping boxes, and return-friendly designs protect products while optimizing the customer experience.

Auto Parts & Accessories Packaging Products

Choosing the right packaging product for your auto parts and accessories is essential to ensure protection, durability, and proper product presentation in both shipping and retail environments. The right packaging—whether corrugated boxes for heavy parts, folding cartons for retail items, or blister packs for small accessories—helps prevent damage, enhances brand visibility, and improves customer experience.

Auto Parts & Accessories Packaging Services

With a dedicated packaging specialist, you will receive personalized support throughout the entire packaging process, ensuring a seamless experience from concept to completion. Your account manager will oversee every detail—from design and prototyping to production and delivery—providing expert guidance, timely updates, and tailored solutions to meet your specific needs.

Our structural design services for auto parts and accessories packaging ensure that every package is engineered for maximum protection, efficiency, and visual appeal. We create custom inserts, dividers, and reinforced structures to secure products like brake pads, car batteries, and performance parts, preventing damage during transit. Our team optimizes packaging for both retail and eCommerce, balancing durability with space efficiency to reduce material waste and shipping costs. Whether you need shock-resistant packaging, moisture protection, or tamper-evident features, our structural designs provide a tailored solution for your product’s unique needs.

Our graphic design services for auto parts and accessories packaging ensure that your brand stands out with high-quality visuals, bold branding, and clear product information. We create custom graphics, logos, and detailed product labeling for packaging solutions like corrugated boxes, folding cartons, blister packs, and retail displays. Whether for retail shelves or eCommerce shipments, our designs enhance brand recognition, attract customers, and communicate key product details effectively. With options like high-resolution printing, eye-catching finishes, and strategic layouts, we help you create packaging that is both visually appealing and functional.

Our sampling and prototyping services for auto parts and accessories packaging allow businesses to test and refine their packaging before full-scale production. We provide custom prototypes for corrugated boxes, folding cartons, blister packs, and displays, ensuring the perfect fit, durability, and visual appeal for your products. By evaluating structural integrity, material performance, and print quality, our sampling process helps identify potential improvements and ensures optimal protection and branding. This approach minimizes risk, reduces costs, and guarantees that your final packaging solution meets both functional and aesthetic requirements.

Our product and material testing services ensure that packaging provides the necessary strength, protection, and reliability for various auto parts and accessories. We evaluate materials for impact resistance, compression strength, moisture control, and overall durability to ensure they can handle the demands of shipping and storage. By testing different packaging solutions under real-world conditions, we help businesses optimize their designs for cost efficiency, sustainability, and performance. This process ensures that your packaging not only protects your products but also maintains its integrity throughout the supply chain.

Our auto parts and accessories packaging is designed for maximum durability and protection, ensuring that products remain secure during shipping, storage, and handling. With reinforced materials, shock-absorbing inserts, moisture barriers, and tamper-evident features, our packaging solutions prevent damage, reduce returns, and keep products in optimal condition.

Packaging durability starts with choosing the right materials, whether it’s corrugated board for heavy-duty parts, folding cartons for retail displays, or blister packs for small accessories. High-quality materials provide strength, flexibility, and protection against external elements like moisture, dust, and impact. Auto parts packaging often requires multi-layered or reinforced materials to support weight and prevent damage. Selecting the appropriate material ensures cost-efficiency, sustainability, and product safety throughout the supply chain.

The thickness and strength of packaging materials directly impact the level of protection auto parts receive. Heavier components, like brake pads and batteries, require double-wall or triple-wall corrugated boxes for added durability. Proper thickness prevents crushing, punctures, and deformation during transit and storage. Custom-engineered packaging solutions ensure that each product has the right balance of protection and cost-effectiveness.

Protection: Sensitive electronic components, such as ECUs, sensors, and wiring harnesses, require ESD-safe packaging to prevent damage from static electricity. Conductive and dissipative materials help shield delicate parts from electrostatic buildup, ensuring they remain fully functional upon delivery. ESD foam inserts and anti-static bags add an extra layer of protection by neutralizing harmful charges. Implementing ESD-safe packaging reduces failure rates, warranty claims, and costly product returns.

Custom inserts provide critical protection by securing parts in place and minimizing movement during transit. Foam, corrugated, or molded pulp inserts are commonly used for delicate or high-value auto parts like headlights, performance parts, and electronics. Inserts help prevent scratches, breakage, and component shifting, reducing the risk of damage. They also enhance the unboxing experience, making the product easier to access and display in retail settings.

Auto parts packaging must be engineered for maximum durability and load-bearing capacity to withstand the rigors of shipping and storage. Reinforced corners, multi-layered walls, and strategic cutouts enhance the strength of packaging without adding excessive weight. Structural design plays a crucial role in protecting fragile, heavy, or oddly shaped parts from crushing or impact. Proper engineering ensures that the packaging maintains its integrity under pressure while keeping the product secure.

Auto parts often experience rough handling, drops, and stacking pressure throughout the supply chain, making impact resistance essential. Cushioned materials, reinforced box flaps, and shock-absorbing layers help mitigate damage from sudden impacts. Protective packaging solutions, such as double-wall corrugated boxes and foam-lined inserts, absorb shocks and vibrations effectively. A well-designed packaging system ensures that even the most fragile parts arrive undamaged and ready for use.

Humidity, condensation, and environmental exposure can cause metal components to rust or degrade during storage and transit. Moisture-resistant coatings, VCI (Volatile Corrosion Inhibitor) bags, and sealed packaging help prevent corrosion and extend product lifespan. Corrugated boxes with water-resistant treatments add another layer of defense against external conditions. Proper moisture control ensures that auto parts maintain their integrity from the warehouse to the customer’s hands.

Ensuring product authenticity and security is crucial in the auto parts industry, where counterfeit or tampered goods can lead to safety issues. Tamper-evident seals, breakaway closures, and RFID tracking provide an added layer of protection against unauthorized access. These security features help prevent theft, contamination, and warranty fraud, giving customers confidence in the product’s integrity. Secure packaging solutions also reinforce brand trust and compliance with industry regulations.

Modern packaging solutions balance durability with eco-friendly materials, reducing environmental impact without compromising strength. Recyclable corrugated boxes, biodegradable inserts, and water-based inks ensure that packaging remains both robust and sustainable. Reinforced paper-based materials and reusable designs offer long-term durability while minimizing waste. By incorporating sustainability into packaging, businesses can meet eco-conscious consumer demands while maintaining top-tier protection.

ecure closures are essential for keeping packaging intact throughout handling, transit, and storage. Tuck-top designs, reinforced flaps, and heavy-duty adhesives prevent packaging from opening unintentionally. For heavier auto parts, locking tabs, cherry locks, and industrial-strength tape offer added security. Well-designed closure mechanisms help protect contents from external elements while ensuring ease of use for customers.

Finding the right auto parts and accessories packaging requires expertise, high-quality materials, and tailored solutions to ensure maximum durability and protection. At Brown Packaging, we specialize in custom packaging design, structural engineering, material selection, and secure packaging solutions for all types of automotive products. Whether you need heavy-duty shipping boxes, retail-ready displays, moisture-resistant packaging, or tamper-evident solutions, our team is here to help. Contact us today to discuss your packaging needs and let our experts create the perfect solution for your business.