Wholesale Corrugated Packaging Supplier

Stock Corrugated Packaging

Discover the convenience of our stock corrugated packaging solutions. As your all-in-one packaging supplier, we offer a wide selection of corrugated products in standard sizes and materials accompanied by customizable pads and inserts. From small delicate items to large bulk goods, our high-quality boxes provide optimal protection during storage and transportation, ensuring customer satisfaction every time.

Wholesale Corrugated Packaging Supplier

Stock Corrugated Packaging

Discover the convenience of our stock corrugated packaging solutions. As your all-in-one packaging supplier, we offer a wide selection of corrugated products in standard sizes and materials accompanied by customizable pads and inserts. From small delicate items to large bulk goods, our high-quality boxes provide optimal protection during storage and transportation, ensuring customer satisfaction every time.

What is Corrugated Material?

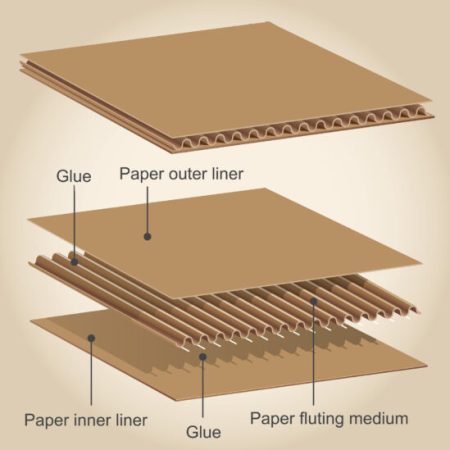

Corrugated material, also known as corrugated cardboard, is a versatile packaging material composed of three layers: two flat outer layers called linerboards and a wavy inner layer known as the corrugating medium. The fluted inner layer provides strength and flexibility, while the outer layers offer rigidity. Corrugated material is valued for its durability, cost-effectiveness, and recyclability. It provides excellent protection, is lightweight for efficient transportation, and is made from renewable sources. It is widely used in various industries due to its strength, versatility, and environmental sustainability.

Our Corrugated Products

Experience the exceptional versatility of corrugated material, a widely recognized and commonly used packaging solution worldwide. Explore our popular range of corrugated packaging supplies, including but not limited to boxes, pads and inserts designed to meet your diverse packaging needs with excellence.

Corrugated Packaging Options

Discover a wide array of corrugated packaging options to suit your specific needs. Explore our range of standard box sizes, edge crush and Mullen’s burst strength ratings, flute sizes, and customizable solutions for a comprehensive selection of packaging solutions that meet your unique requirements.

-

Edge Crush (ECT)

-

Mullens Burst

-

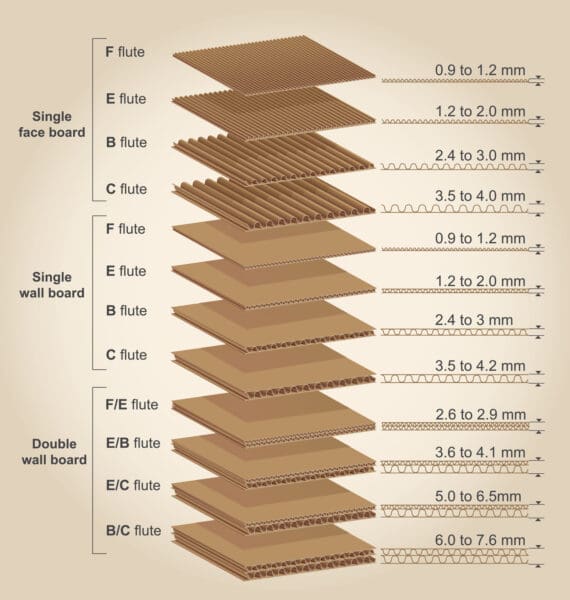

Flutes (A, B, C, E & F)

-

Wall (Single, Double and Triple)

-

Custom Corrugated

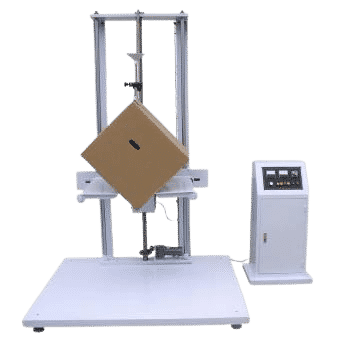

The Edge Crush Test (ECT) is a standardized testing method used to evaluate the edge crush resistance of corrugated cardboard materials. It measures the ability of the material to withstand pressure applied to its edges without collapsing or deforming.

Purpose:

The purpose of the Edge Crush Test (ECT) is to assess the stacking strength and load-bearing capacity of corrugated cardboard. By subjecting the material to controlled pressure, the test determines its resistance to compression along the edges, providing valuable information about its ability to protect packaged goods during transportation and storage.

Application:

The Edge Crush Test (ECT) is widely employed in the packaging industry to ensure the strength and reliability of corrugated materials. It is particularly important when packaging goods that require stacking or are subject to heavy loads. By conducting the ECT, packaging professionals can make informed decisions about material selection, packaging design, and load-bearing capabilities. The ECT value obtained from the test helps meet industry standards, comply with regulations, and ensure the packaging’s ability to withstand external forces encountered throughout the supply chain.

Corrugated Board Strength Equivalencies: Single Wall Corrugated

Corrugated Board Strength Equivalencies: Double Wall Corrugated

The Mullen Burst Test is a standardized testing method used to assess the burst strength of corrugated. It measures the ability of the material to withstand internal pressure without bursting or breaking.

Purpose:

The primary purpose of the Mullen Burst Test is to evaluate the strength and durability of corrugated for packaging applications. The test determines the maximum pressure a material can withstand before bursting, providing valuable information about its resistance to external forces and the ability to protect the contents during transportation and storage.

Application:

The Mullen Burst Test is widely utilized in industries such as manufacturing, distribution, and logistics to ensure the quality and reliability of packaging materials. By conducting this test, packaging engineers and designers can select appropriate materials, optimize packaging designs, and ensure the integrity and safety of packaged goods. The burst strength value obtained from the test helps determine compliance with industry standards and regulations, ensuring that packaging meets the necessary requirements for strength and performance.

Corrugated Board Strength Equivalencies: Single Wall Corrugated

Corrugated Board Strength Equivalencies: Double Wall Corrugated

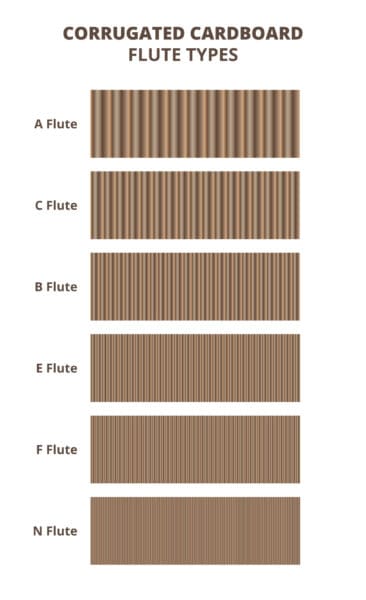

Corrugated flute A is an extra-large flute size, specifically designed for heavy-duty and specialized applications. With the largest wave height, it offers maximum strength and crush resistance. Corrugated Flute A is commonly used in industries such as automotive, aerospace, and industrial manufacturing, where large and heavyweight items require superior protection. It provides exceptional durability and can withstand extreme handling and transportation conditions. Corrugated Flute A is typically available as a custom option tailored to specific requirements, ensuring optimal performance for challenging packaging needs.

Corrugated flute B is one of the most commonly used flute sizes, offering a versatile balance between strength and thickness. With medium-sized waves, it provides reliable cushioning, protection, and stacking strength. Corrugated Flute B is well-suited for a wide range of applications, including shipping boxes, retail packaging, e-commerce packaging, and point-of-purchase displays. It can handle a variety of products, from lightweight items to moderately heavy products, making it a popular choice across various industries. B Flute is used for die cut boxes such as tuck top mailers, bin boxes and folders.

Corrugated flute C is a medium-sized flute, known for its strength and versatility. With larger waves compared to flute B, it offers excellent crush resistance and structural stability. Corrugated Flute C is commonly used for heavy-duty packaging applications that require enhanced stacking strength and protection. It is suitable for shipping boxes, industrial packaging, bulk storage, and applications where items may undergo rigorous handling or face challenging transportation conditions. C Flutes are used for stock corrugated boxes such as RSC, HSC and FOL.

Corrugated flute E is an small flute size, known for its exceptional rigidity and crush resistance. It offers outstanding stacking strength and structural stability. Corrugated Flute E is commonly used for heavy-duty packaging requirements, including bulk containers, furniture, industrial equipment, and other applications where added strength and durability are essential. It provides excellent protection against compression, making it suitable for demanding transportation and storage conditions.

Corrugated flute F, also known as Micro Flute or Mini Flute, is a fine flute size characterized by its small, dense waves. It offers excellent printability, making it ideal for packaging designs that require high-quality graphics and detailed printing. Corrugated Flute F provides a smooth surface, allowing for vibrant colors and sharp images. While less common in standard offerings, Corrugated Flute F is available for custom applications where a premium appearance and superior printability are desired. It is often used for retail packaging, point-of-sale displays, and specialty packaging where aesthetics and visual appeal are crucial.

It’s important to note that the selection of the appropriate flute type depends on various factors, including the weight and fragility of the packaged product, transportation conditions, and specific packaging requirements. Consulting with us can help you determine the most suitable flute type for your specific application.

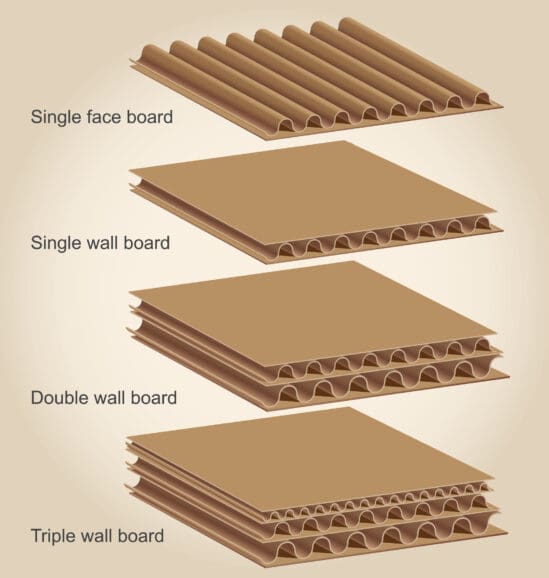

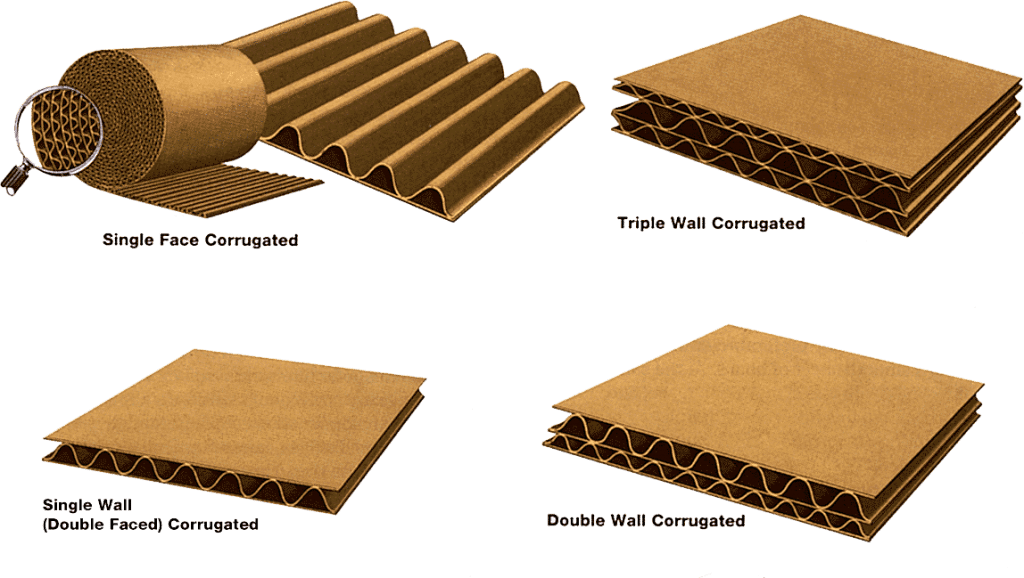

Single wall corrugated consists of a single flute sandwiched between two flat linerboards. It is the most common and versatile type of corrugated material. Single wall corrugated offers lightweight yet sturdy protection for a wide range of products. It provides cushioning, structural integrity, and some resistance to external forces. Single wall corrugated is commonly used in various industries for shipping boxes, retail packaging, e-commerce packaging, displays, and other applications where moderate strength and cost-effectiveness are required.

Double wall corrugated consists of two layers of flutes separated by three flat linerboards. This construction provides enhanced strength and durability compared to single wall corrugated. Double wall corrugated offers superior cushioning, stacking strength, and resistance to impacts and compression. It is suitable for heavier products, fragile items, and applications that require extra protection. Double wall corrugated is commonly used in industrial packaging, bulk shipping, heavy-duty retail packaging, and applications where added strength and rigidity are necessary.

Not available in stock, triple wall corrugated consists of three layers of flutes separated by four flat linerboards. This construction offers the highest level of strength and protection among the standard corrugated options. Triple wall corrugated provides excellent cushioning, stacking strength, and resistance to heavy loads and rough handling. It is ideal for large and heavy products, machinery, equipment, and other applications that demand maximum strength and durability. Triple wall corrugated is commonly used in industrial packaging, export shipping, and specialized applications requiring exceptional performance.

Single face corrugated features one flat linerboard and a layer of flutes on one side. This construction provides a lightweight yet flexible packaging material. Single face corrugated offers cushioning, protection, and versatility. It is commonly used as an inner packaging material, dividers, protective wrap, and as a surface protector for fragile items. Single face corrugated is also utilized for creative applications such as signage, temporary displays, and artistic projects due to its easy manipulation and printable surface.

These categories of corrugated materials offer a range of options to accommodate different packaging requirements, providing varying levels of strength, protection, and versatility. Selecting the appropriate corrugated type depends on factors such as product characteristics, weight, fragility, transportation conditions, and specific packaging needs. For assistance please contact Brown Packaging.